Occupational Health and Safety

JSC NC “KazMunayGas” and its subsidiaries and dependent entities prioritise the lives and health of employees over the production performance, prevention of occupational health and safety hazards. KMG Group’s Health and Safety Policy is based on the commitment of top management to health and safety, aiming to involve every employee in development of safety culture. Management of the Company and its SDEs exercise zero tolerance to losses and damage due to accidents and incidents, abuse of alcohol, drugs, psychotropic substances and their equivalents, road traffic accidents. The Company’s commits to follow the national law alongside requirements of international and national standards.

Key Figures of 2021

Protecting the lives and health of employees and safe working conditions are the top priorities for the company. One of KMG’s strategic initiatives is Sustainable Development of All Business Areas, so the company pays particular attention to maintaining a high level of occupational safety in line with global standards and best practices.

At the end of 2021, the number of work-related accidents in KMG has decreased by 7% compared to last year (from 30 in 2020 to 28 in 2021), the number of injured workers is at the same level as in 2020.

In 2021, there was one work-related fatal accident where 3 employees died (due to fire at Petromidia Refinery, Romania).

|

Key OHS indicators* |

UoM |

2019 |

2020 |

2021 |

D2021/2020 |

% |

|

Accidents |

Case |

41 |

30 |

28 |

-2 |

-7 |

|

Injured in accidents |

Person |

48 |

32 |

32 |

0 |

– |

|

Road traffic accidents |

Incident |

44 |

15 |

22 |

+7 |

47 |

|

Fires |

Incident |

10 |

6 |

6 |

– |

– |

The number of road traffic accidents increased by 47% (from 15 accidents in 2020 to 22 in 2021). However, of the 22 accidents that occurred in 2021, 10 were caused by a third party. Number of fires in 2021 – 6 incidents.

About the Fire at Petromidia Refinery, Romania

On 2 July 2021, at 12:15, 122V8 feed tank exploded and a fire broke out at Petromidia Refinery. The fire was extinguished at 15.10. Five people were injured in the incident, of whom: 3 workers died; 2 workers fully recovered. Affected workers and their families received financial, medical and psychological support from the Company.

Resumption of Petromidia Refinery Operation

The refinery was restarted on 24 September 2021 – the crude oil refining process started at the oil unit after being shut down for 83 days (from 2 July 2021 to 24 September 2021) and also after the proper approvals for restart were obtained. Between 24 and 28 September 2021, the main refining units (soft hydrocracker, naphtha hydrotreater, catalytic cracker (FCC), delayed coker) were successfully started up. The only non-functional unit is DHT, which was most affected by the 2 July 2021 incident and, according to the updated plan, will be restarted after the planned shutdown of the refinery in April 2022.

Actions

More than 20 companies were involved in the work and the total number of people who restarted the units was around 1000 (employees of Rompetrol Rafinare, Rominserv and specialists from contracting companies). Inspections, repairs and significant replacement of pipes have been carried out, and necessary equipment has been restored. Instrumentation and electrical cables were also replaced, all elements and equipment related to operational safety were checked at each unit, and refinery personnel were retrained and recertified.

HSE Measures

KMGI and Petromidia Refinery management has taken additional training measures with amendments to HSE-ES convention, risk analysis for operational personnel and subcontractors, additional training on HSE plan, waste management plan, environmental protection for operational personnel and subcontractors, a centralised safety meeting was held with HSE representatives and management of KMGI, contractor and subcontractors. KMGI is cooperating with the official authorities to investigate the accident under Romanian law.

Expert Review

- The Romanian authorised body INSEMEX and KMGI are investigating the cause of the fire at the request of the Romanian Prosecutor’s Office: the report is due in the first half of this year.

- A report has been received from Omniasis Vienna Insurance on status of damage and cause of fire;

- As instructed by NC KMG’s Board of Directors, KMGI received an Independent Investigation Report from GEXCON on the causes of the fire and recommendations for safety measures.

Preventive Actions

Based on the recommendation of GEXCON, KMGI has developed a corrective action plan. Actions are currently taken in the following areas:

- Safety enhancement measures at Petromidia Refinery hydrotreaters (implementation of additional protection for high-pressure systems);

- Fire-fighting system restoration programme (improvement of reliability and integrity of the firefighting system and off-site utility networks);

- Centralised warning system actions (upgrade and automation of the emergency warning system as planned);

- Personal protective equipment (PPE) actions (stricter requirements for the standard of protective clothing for workers).

To prevent similar incidents in the future and improve process safety management, KMGI has developed information materials for hazard studies and personnel informing of past and potential incidents in the workplace.

KMGI’s corrective action plan has been sent to KMG, AR and POCR occupational safety management departments.

Lessons learned from previous incidents were also sent to KMG, AR and POCR as part of the on-site process safety management.

ACCIDENT AND FATALITY RATE IN KMG

|

Indicator* |

2019 |

2020 |

2021 |

IOGP |

|

Lost Time Accident Rate per mln man-hours |

0.31 |

0.25 |

0.31 |

0.20 |

|

Fatal Accident Rate per 100 mln man-hours |

1.28 |

0 |

2.93 |

0.56 |

Production Process Safety Management

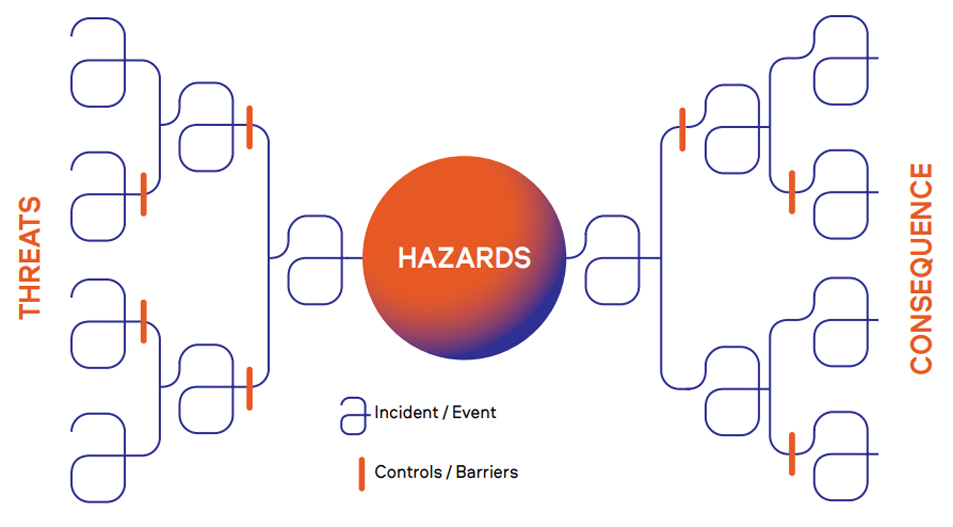

Since 2021, the Company has been gradually implementing a Process Safety Management System (PSM) at KMG’s production facilities, which aims to prevent major catastrophic incidents (emergencies, incidents, fires and accidents), including:

-

Maintaining integrity of assets and process equipment;

- Establishing safe operational rules, standards and procedures in accordance with Statutory Requirements of the Republic of Kazakhstan, industry standards, best international PSM practices and approaches (IOGP, OSHA);

- Identifying process risks and employing relevant measures to prevent or mitigate them;

- Avoiding damage to and loss of life and health of the Company’s employees and population, environment, financial and legal implications, property and assets, reputation and image.

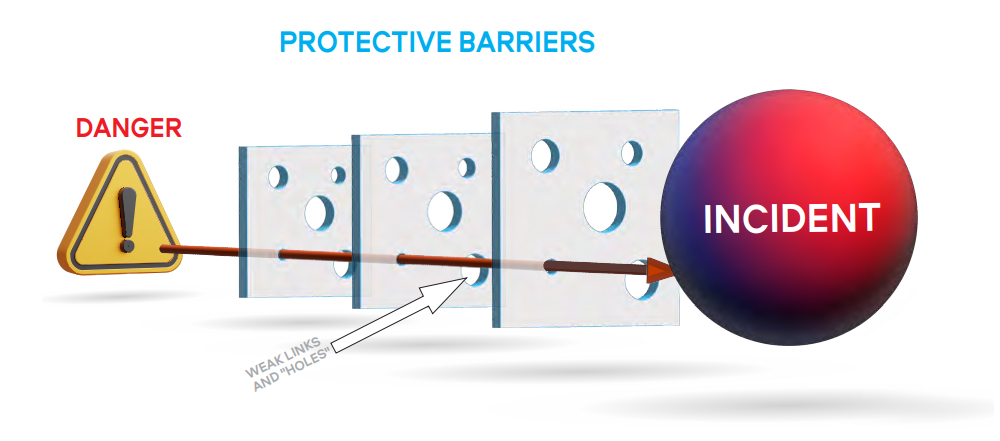

The Company believes that the combination of engineering and management elements is effective and aims to prevent major catastrophic incidents involving loss of containment of process equipment and resulting in structural collapse, explosions, fires, destructive releases and spills of hazardous substances (chemicals, oil and petroleum products). Such engineering and management elements surpass the workplace safety management requirements, as they affect people, property and environment.

The Company uses key performance indicators (KPIs) to monitor and review the Process Safety Management System:

- Lagging indicators allowing to track, record the actual integrity, system failures, number of incidents;

- Leading indicators that systematically measure the indicators allowing to assess the performance of protective and control systems and mechanisms that make up barriers.

To further implement the Process Safety Management System, a scorecard is planned for 2022 to verify the operation of critical protective measures/barriers at the Company’s production facilities.

Transportation Safety

In terms of RTA statistics, we would like to point out that there are accident risk factors that are beyond the control of the Company. One such factor is the large number of vehicles (more than 10,500) that are in daily use at our production facilities. The second factor is the geographical location of the Company’s subsidiaries, scattered throughout the Republic of Kazakhstan, as well as their location in major cities and settlements where there is a high risk of RTA caused by a third party. Namely: out of the total of 22 accidents in 2021, 10 were caused by other road users.

In order to reduce the risk of road accidents, the Company has implemented the following set of transport safety measures:

- Recommendations for the Action Plan on the RTA Prevention List in Subsidiaries have been developed to operate vehicles safely and to preserve the life and health of the Company’s employees.

- Training courses have been held for drivers as scheduled to test their knowledge of RoK Traffic Rules and updated corporate documents of the Company’s Policy and Regulations on the Safe Operation of Land Vehicles.

- In order to improve transport safety, the Company and its contractors held a Seatbelt precaution event in March 2021.

- A Safe Vehicle Driving video was filmed in September 2021 in order to raise awareness among employees of the Company and subsidiaries, and promote a culture of safe driving.

- Winter Traffic Safety preventive actions were taken in November 2021 due to the autumn-winter period and high risk associated with the seasonal increase in traffic accidents.

- Travel Management pilot project was initiated and implemented at Embamunaygas JSC through creation of a safe driving culture based on the best international practices, modern digital solutions and process automation. EMG facilities have completed stage I of this project – a unified vehicle monitoring system has been implemented. Stage II scheduled for Q1 2022 includes the route deviation monitoring and connection of contractors’ vehicles to the unified vehicle monitoring system.

In 2022, it is planned to replicate the Travel Management project aimed at improving transport safety, reducing road accidents, smart planning and accounting, and monitoring the efficiency and targeted use of vehicles and fuel and lubricants.

It is also planned to train coaches from among the Company employees (transport/road safety engineers) in 2022 in Defensive Driving to international accreditations from OPITO, ROSPA, etc.

Fire Safety

In 2021, there were 6 fires in KMG Group (the number of fires is same as in 2020), of which 2 incidents are major fires with loss of life (3 deaths and 1 injury) and significant material damage.

Investigations into the circumstances and causes of fires identified the following main systemic causes:

- poor commitment and leadership of top management and line managers;

- low safety culture and competence of managers/officers;

- insufficient funding for industrial and fire safety measures;

- inappropriate risk assessment and management of ’barriers’;

- poor fire evacuation drills in dormitories and camps.

In order to prevent and avoid fires and ignitions, the Company has taken the following preventive fire safety measures:

- Following the occurred major fires, the measures to prevent and avoid fires in the Company were immediately put into effect with special emphasis placed on fire drills and exercises both at the production facilities and in the camps.

- Based on the analysis of reports submitted by the subsidiaries, in November and December 2021, random inspections of implementation of measures to prevent and avoid fires in dormitories and camps were conducted in all business areas of the Company.

- In order to strengthen control over compliance with fire safety requirements and improve the Company’s preparedness for prompt fire response, 2022-2024 Comprehensive Plan was developed and approved to provide short, medium and long-term, as well as preventive measures to ensure fire safety at the Company’s facilities.

- The rules for inspection and assessment of fire prevention and response preparedness of KMG Group companies have been updated and re-approved subject to requirements of RoK law in the field of fire safety, HSE Management System Guidelines in KMG Group, international standards and IOGP recommendations.

- In order to promote fire safety and raise personnel awareness, a fire safety leaflet for employees and visitors was developed and Fire Safety Month was held from 4 October to 4 November 2021 in the Company’s office.

- In order to reduce the risk of fires and ignitions during New Year holidays and long weekends, in December 2021 a letter was sent to all business areas of the Company to take additional measures to comply with fire and electrical safety requirements at both production facilities and camps.

The following initiatives are planned for 2022 to improve industrial and fire safety in the Company:

- Introduction of new approaches to HAZOP study using a third-party specialist company in Rompetrol;

- Comprehensive risk assessment identifying potentially hazardous facilities and equipment using the Risk Based Inspection (RBI) method with the support of Samruk-Kazyna JSC;

- Implementation of short-term measures of 2022-2024 Comprehensive Fire Safety Plan approved by the Chairman of the Company’s Management Board;

- Review and assessment of the preparedness of non-state firefighting services to prevent and extinguish fires at the Company’s facilities as part of the Contractor Management Process.