Environmental Performance

KMG Group’s operations are focused on minimising its environmental impact, using natural resources sustainably and preserving biodiversity.

We recognise our responsibility to society for sustainable use of natural resources and preservation of a favourable environmental situation in the regions where we operate, and are committed to ensuring sustainable use of natural resources, consistently reducing our impact on the environment through introduction of energy and resource saving, low-waste, environmentally friendly technologies, equipment, materials, climate change adaptation measures and compensation for possible environmental damage.

A number of measures has been implemented in recent years to increase the effective utilisation of raw gas, resulting in this indicator improving and reaching 98%. We also managed to reduce atmospheric pollutant emissions across KMG Group. There are ongoing oil waste disposal measures, including historic waste, and reclamation of polluted lands. The programme activities being implemented and planned will ensure reduction in water consumption from surface water sources and improvement of the waste water’s qualitative composition. Desalination plants are under construction in Mangystau Region.

Key Figures of 2021

- SOx emission rate – 0.22 (IOGP – 0.19)

- NOx emission rate – 0.24 (IOGP – 0.29) (https://www.iogp.org/)

- associated petroleum gas flaring intensity (APG) – 2.1 (IOGP – 8.0)

- APG utilization rate – 98%

- Restoration of historical waste and oil-contaminated land: 540,500 tonnes (2020 – 558,400 tonnes, 2019 – 324,700 tonnes)

- CDP Climate Rating: "C"

- CDP water security rating: "B-"

Environmental performance, tonnes per 1,000 TOE of HCs production

|

Year |

SOx emission rate |

NOx emission rate |

Raw gas flaring rate |

Raw gas flaring rate |

|

2019 |

0,20 |

0,21 |

2,95 |

97 |

|

2020 |

0,23 |

0,22 |

2,20 |

98 |

|

2021 |

0,22 |

0,24 |

2,09 |

98 |

Year of Environment at KMG Group

A number of environmental safety measures have been implemented during the Year of Environment, such as disposal of historic oil waste and clean-up of oil-contaminated lands. KMG’s Corporate Centre has held a drawing competition among the children of KMG Group employees.

The first stage involved in-house children’s drawing competitions in all SDEs. KMG’s Health, Safety and Environment Department held an Environment through Children’s Eyes drawing competition among employees of the corporate centre.

The second stage of the competition involved all the winners among KMG Group, the finalists were determined through online voting. The winner was Nurasyl Berdaly

KMG SDEs actively supported all organised activities of the Year of Environment, and environmental awareness raising among employees was strengthened, with periodic clean-up days, drawing competitions for employees’ children, participation in tree planting campaigns, development of action plans to reduce air emissions, implementation of environmental protection programmes and other events, such as:

- Earth Hour international environmental campaign;

- Month’s clean-up and landscaping campaign in the regions where we operate;

- Birge Taza Kazakhstan republican campaign;

- Oz Agashındı Otırgız environmental campaign;

- Plastic Monster regional environmental competition;

- Employees regularly cleaned and tidied up the territory and took part in city-wide clean-up days;

- Trees were planted within sanitary protection zones.

World Cleanup Day 2021 took place on 18 September in 191 countries. As part of this global movement and republican eco-initiative Birge-Taza-Kazakhstan! and KMG’s Year of Environment, a tree-planting event was held jointly with the Almaty District Akimat of Nur-Sultan. About 100 pine trees were planted by the Company’s employees in the capital during a city-wide clean-up day on 18 September.

The commitment to environmental responsibility is also reflected in landscaping work at KMG SDEs. It is planned to carry out Landscaping by Major Oil Companies for 2021-2024 in KMG SDEs located in Atyrau Region as instructed by the President of the Republic of Kazakhstan K. Tokayev announced in the Message to the people of Kazakhstan, and also under the Complex Plan to plant more than 2 billion trees in forests and 15 million in the settlements.

All KMG SDEs have planted green vegetation in the sanitary protection zones and in the regions where they operate. For example, Karazhanbasmunay JSC employees cleaned up and planted 3,000 saplings in the territory of Karazhanbas field and a number of socially important facilities in Mangystau Region. Pavlodar Refinery LLP has planted 6,680 trees on an area of 21.5 hectares within the sanitary protection zone. The company employees have planted 84 trees on the industrial site.

A Memorandum of Understanding was signed between the Atyrau Region Akimat (Mayor's Office) and Embamunaygas JSC in April 2021 on Landscaping in Atyrau Region with a total scope of 243.2 hectares. Soil Surveys on the Allocated Land Plot have been conducted under the landscaping programme. Landscaping is planned in the territory based on the soil surveys and identification of land plots suitable for planting.

Under the Memorandum on Landscaping in Atyrau signed in April 2021 with the Atyrau Region Akimat, Atyrau Refinery LLP has been allocated the land plots in Atyrau with a total area of 1,420.9 ha, including 860.9 ha of Tukhlaya Balka evaporation field. In order to fulfil the Memorandum conditions on an area of 560 hectares, a research company with experience and scientific expertise in afforestation has been engaged by the refinery. Based on the survey, the allotment is not suitable for landscaping and work is underway to identify a new land plot. Once the additional land plot for landscaping is identified, the refinery will develop a landscaping and greening project, determine an estimated cost and scope of work, and a schedule of work. Atyrau Refinery LLP has carried out additional landscaping and greening on a 5 ha area within the Sanitary Protection Zone (SPZ) to the west of the refinery (not included in the approved SPZ feasibility study in terms of landscaping).

Employees also regularly cleaned and tidied up the territory.

Priority Environmental Projects

TAZALYQ Project

TAZALYQ project includes upgrading the waste water treatment facilities of Atyrau Refinery LLP and remediation of Tukhlaya Balka evaporation ponds.

Project to Build a Formation Water Treatment Plant at Karazhanbas Field

Construction of a formation water treatment plant at Karazhanbas field will solve the problem of water scarcity at the field.

Automated Environmental Monitoring Information System Project

It is used in the preparation and submission of various environmental reports and the planning of environmental protection measures. The goal is to obtain accurate and reliable data, generate the comprehensive and up-to-date environmental information that is needed for effective environmental policy as well as for development programmes.

Recovery of Historic Oil Waste and Oil-Contaminated Land Clean-up

Complete disposal of historic oil waste and clean-up of oil-contaminated lands up to and including 2024.

Green Office Principles in KMG

Green Office principles are concerned with conserving all resources and taking care of the environment. KMG takes steps to implement Green Office requirements, which include measures to continuously improve working conditions, comfort, productivity, design and architecture, greenery and recreational opportunities.

The following steps have been taken to date:

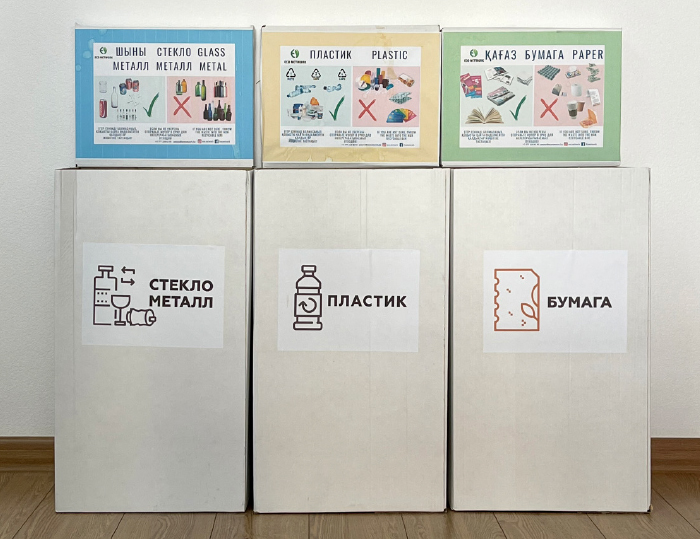

- installation of eco-bins in offices, hallways, lobby, parking area for separate waste collection: paper, plastic, glass and metal;

- video clip on separate waste collection at the end of each month will be shown on displays in the lifts and lobby of the Emerald Business Centre;

- pop-up window to switch off computers and equipment on employees’ screens at the end of the working day;

- sticker with slogans to save trees, minimise printing, use double-sided and black-and-white printing, print unofficial documents on the “backs” of drafts not containing confidential information;

- in order to protect employees from the harmful effects of personal computers, a pop-up window option has been installed telling them to take five minutes off their PC and exercise at 11.00 and 16.30;

- Environment Calendar 2021 was issued for KMG employees;

- awareness raising campaign is conducted through internal mailing of posters, brochures, videos and presentations on the Green Office concept;

- slides about eco-bins for separate waste collection in the office have been added to the onboarding programme for newly hired employees.

To implement the Green Office concept in KMG’s Corporate Centre, a target has been set to reduce consumption of writing paper by 3% versus 2019. In 2021, 3,059 packs of paper were used, which is 23.5% below the planned 4,000 packs and 75% below the target (12,228 packs were used in 2019).

Environmental Assessment of Planned Economic Activities

The Company conducts environmental assessment of proposed economic activities at all stages of the project life cycle from the declaration of intent to construction and operation projects in line with legal requirements and best international practices. We are in regular contact with representatives of the local community and take their views into account when planning and implementing projects. Public hearings are held at each design stage with stakeholder representatives to enable access to draft EIAs for all stakeholders and record comments and suggestions. All KMG Group’s draft EIAs are subject to state environmental expert review and are available to the public concerned. In 2021, 24 meetings with local communities and public organisations and 34 public hearings were held, and media tours to production facilities were conducted. The number of offline public hearings has been reduced due to restrictions imposed because of the coronavirus emergency.

In 2021, the Company’s Board of Directors approved the Corporate Standard for Environmental Impact Assessment. The Standard defines corporate principles of the process of assessing the environmental impact of planned activities, regulates the activities of KMG Group, employees and contractors of KMG Group, including design organisations which activities are related to development of technical documentation and materials for environmental impact assessment, ensuring consideration of the public opinion on the environmental impact assessment related materials as well as obtaining the emission permit.

Engagement with Public Organisations

In 2021, an environmental ombudsman started working at one of our refineries to:

- represent the regional public, local environmental NGOs at the refinery;

- monitor the environmental impact of the refinery’s operations and inform the residents about it;

- respond to questions from residents to the refinery management;

- establish a meaningful dialogue between Atyrau Refinery and the public.

In December 2021, the environmental ombudsman held a report meeting with the public on the progress of Atyrau Refinery LLP’s environmental action plan with the involvement of refinery managers, regional environmental department, regional maslikhat (local representative body) deputies, representatives of regional environmental NGOs, bloggers, activists and the Regional Consumer Rights Protection Society, etc.

There was a meaningful and open dialogue between the refinery management and the public, who received competent answers to all their questions.

Air Protection

In support of the strategic initiative “Sustainable Development of All Business Areas”, the Company follows the principle of zero tolerance towards pollution-related losses and damages and operates in accordance with national environmental legislation and best international practices. The Environmental Policy has been revised to implement the objectives of the new environmental law of the RoK. SDEs are guided by KMG Group’s Atmospheric Emission Management Policy in their operations.

One of the key areas for minimising the environmental impact is reduction of air pollutant emissions from the Company’s operations. Measures to reduce air pollutant emissions include the following activities:

- Obsolete burners on oil heaters are being gradually replaced;

- Integrated gas treatment and processing facilities are under construction;

- Work is underway to install pontoons for vertical oil tanks to prevent evaporation of hydrocarbons.

- Catalytic converters for pollutant emissions are installed on oil heaters, etc.

The regions pay special attention to monitoring the emissions from their production facilities, primarily those located near or within the boundaries of populated areas. To ensure air quality in populated areas, KMG Group is implementing projects to reduce pollutant levels and is also taking measures to set up air quality control systems and install stationary air quality monitoring stations at the boundaries of sanitary protection zones.

We conduct operational environmental monitoring and take measures to reduce air pollutant emissions generated by the operations and processes. As part of the operational environmental monitoring programmes, monitoring of air emissions is done in the designated sampling points and measurements are taken to assess the potential impact. The bulk of pollutant emissions is generated by heating gas burned in boilers, process furnaces and compressors, gas turbine plants, compressor stations, gas flaring, etc.

The permitted volume of all pollutant emissions across KMG amounted to 110.2 thous. tonnes in 2021 (247.2 thous. tonnes in 2020). There has been a reduction in emissions over the last 3 years.

Gross atmospheric pollutant emissions within KMG Group, thous. tonnes

|

|

2019 |

2020 |

2021* |

|

Total atmospheric pollutant emissions, including: |

264.8 |

247.2 |

110.2 |

|

NOx emissions |

18.5 |

17.6 |

12.7 |

|

SOx emissions |

12.3 |

12.7 |

12.2 |

|

other pollutant emissions |

234.0 |

216.9 |

85.3 |

The completed projects for upgrade of oil refineries enabled better environmental performance of fuel produced by the refineries through production of K4-K5 oil products to the European quality standards in compliance with the Customs Union Technical Regulations.

Specific pollutant emissions within KMG Group

|

|

2019 |

2020 |

2021 |

|

HCs production, t / 1000 toe of produced raw hydrocarbons |

1.7 |

1.9 |

1.9 |

|

Oil refining, t / 1000 t of refined oil |

2.9* |

2.9 |

2.8 |

|

Oil transportation, t / 1000 of transported oil |

0.5 |

0.5 |

0.5 |

|

Gas transportation, t / 1000 toe of transported gas |

1.5 |

1.6 |

1.6 |

We do not yet make direct, real-time measurements using, for example, gas analysers, however, in accordance with the new Environmental Code, the authorised environmental body plans a general switch to automated monitoring of pollutant emissions by installing sensors/ gas analysers at emission sources of Category 1 natural resources use facilities. SDEs are adjusting projects to implement an automated emission monitoring system directly at emission sources, and a number of projects are undergoing state environmental expert review.

In 2021, the average ratio of NOx emissions to the total produced raw hydrocarbons in oil equivalent for KMG Group amounted to 0.24 tonnes per thousand tonnes of produced HCs, while average IOGP value is 0.29. Specific NOx emissions have increased by 9% versus 2020 due to addition of new emission sources. The average ratio of SOx emissions to the total produced raw hydrocarbons in oil equivalent for KMG Group amounted to 0.22 tonnes per thousand tonnes of produced HCs, while average IOGP value is 0.19. Compared to 2020, there is a 4% reduction in the specific emissions of SОx

In its operations, the Company does not emit persistent organic pollutants.

Sustainable Utilization of Raw Gas

This section reflects data on companies in production sector where processes related to production and beneficial use of raw gas are present.

Managing the greenhouse gas emissions and reducing the gas flaring are among the top priorities for KMG Group. According to the approved Environmental Policy, the Company aims to achieve zero routine gas flaring and to reduce atmospheric emissions from flares. One of the most important tasks in reducing the greenhouse gas emissions is increasing the beneficial use and utilisation of raw gas, minimising gas flaring. The in-house use of gas for heat and electricity generation has increased due to the implemented measures of the raw gas development and processing programmes.

Targeted actions across KMG Group have resulted in an 83% reduction in APG flaring between 2017 and 2021. This has reduced emissions of pollutants and greenhouse gases from the flaring and dispersal of raw gas.

In 2021, the Company’s sustainable utilization of raw gas achieved 98%. The gas flaring rate is at 2.1 tonnes per 1000 tonnes of produced HCs (2.2 in 2020, 2.95 in 2019), 5% below the 2020 figure and 74% below the industry average IOGP value.

Raw Gas Flaring Volume

|

Показатель |

2017 |

2018 |

2019 |

2020 |

2021 |

|

Total raw gas flaring, mln m3 |

315.8 |

148.9 |

80.2 |

57.6 |

52.5 |

|

Rate of beneficial use of raw gas, % |

85 |

93 |

97 |

98 |

98 |

|

Raw gas flaring rate, tonnes per 1000 thous. of produced HCs |

11 |

6 |

2.95 |

2.2 |

2.1 |

In 2015, KMG supported the World Bank’s initiative of Zero Routine Flaring by 2030. The Company aims to minimise the flaring of raw gas. Raw gas flaring under this initiative is reported on an annual basis to the representative office of World Bank in the RoK.

Water Conservation and Sustainable Water Use

Due to the fact that the Company conducts its core business in the Central Asian region, where water is a valuable and scarce natural resource, KMG is aware of its responsibility to society and the environment and is committed to sustainable use of water resources.

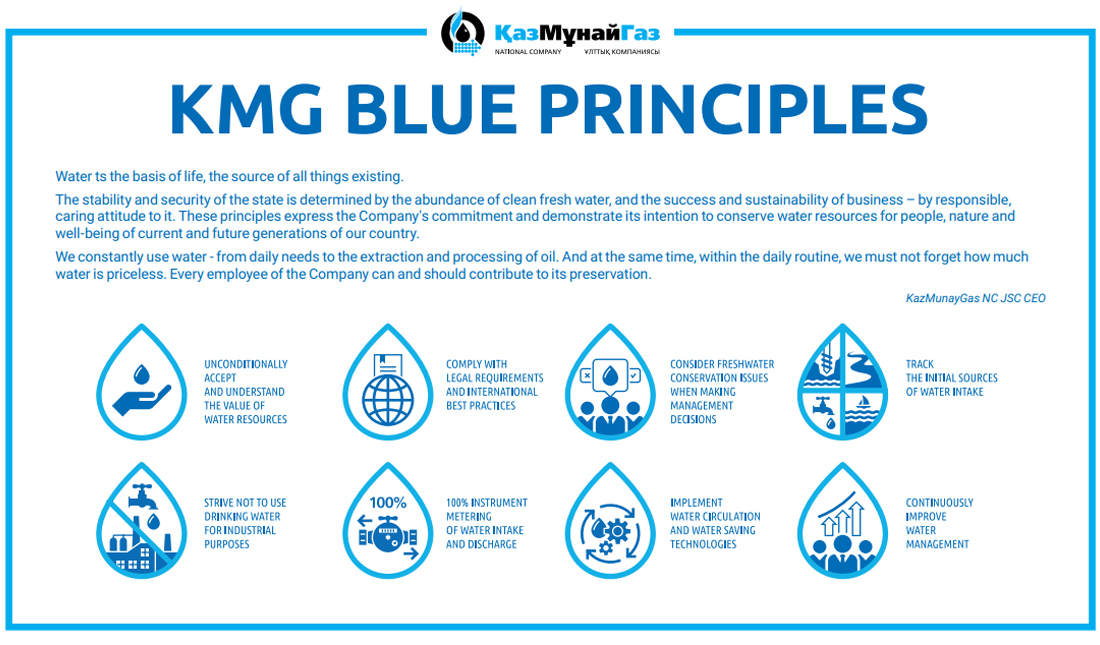

KMG has officially declared its intention to contribute to conservation of water resources in the Republic of Kazakhstan. During the HSE Forum for KMG CEOs, the Chairman of the Management Board A.S. Aidarbayev signed a personal Statement of Commitment to Sustainable Water Management (KMG’s Eight Water Principles). This initiative was supported by the chief executive officers of KMG’s SDEs, who signed similar statements of commitment on behalf of their companies. The signed statements of commitment are posted on the official websites of KMG Group.

The standard states the main water use principles of KMG – eight water principles, systematizes the approach to water management in KMG’s SDEs, as well as helps to enhance the commitment of managers and employees of the Company to fresh water conservation.

Projects aimed at reducing discharges and reducing water withdrawal from natural sources are being implemented.

Atyrau Refinery LLP

One of the main environmental measures is the implementation of TAZALYQ project, which will include the upgrade and reconstruction of mechanical treatment facilities at the AR, reconstruction of biological treatment facilities and construction of a post-treatment unit, and reconstruction of evaporation ponds and the channel for wastewater treated to standard quality.

Reclamation of evaporation ponds involves complete cessation of the plant’s wastewater discharge to ponds (860 ha owned by AR), which will be drained, eliminating adverse impacts on groundwater, flora and fauna of Atyrau Region.

Also, thanks to TAZALYQ project, closed-type mechanical treatment plants will be built at the refinery, and introduction of modern processes will bring wastewater treatment quality to regulatory standards.

Construction of Desalination Plants near the Kenderli recreation area in Mangystau Region

Ozenmunaygaz JSC and KMG Engineering LLP signed a Memorandum of Understanding and Cooperation with the Akimat of Zhanaozen. The signed document involves reclassification of the desalination plant construction feasibility study developed by KMG Engineering LLP as a social project according to the protocol order of the Prime Minister of the Republic of Kazakhstan A.U. Mamin dated 18 September 2019. The desalination plant is planned to be built at the expense of KMG near Kenderli recreation area of Mangystau Region. The expected capacity will be 50 thous. m3 of water per day.

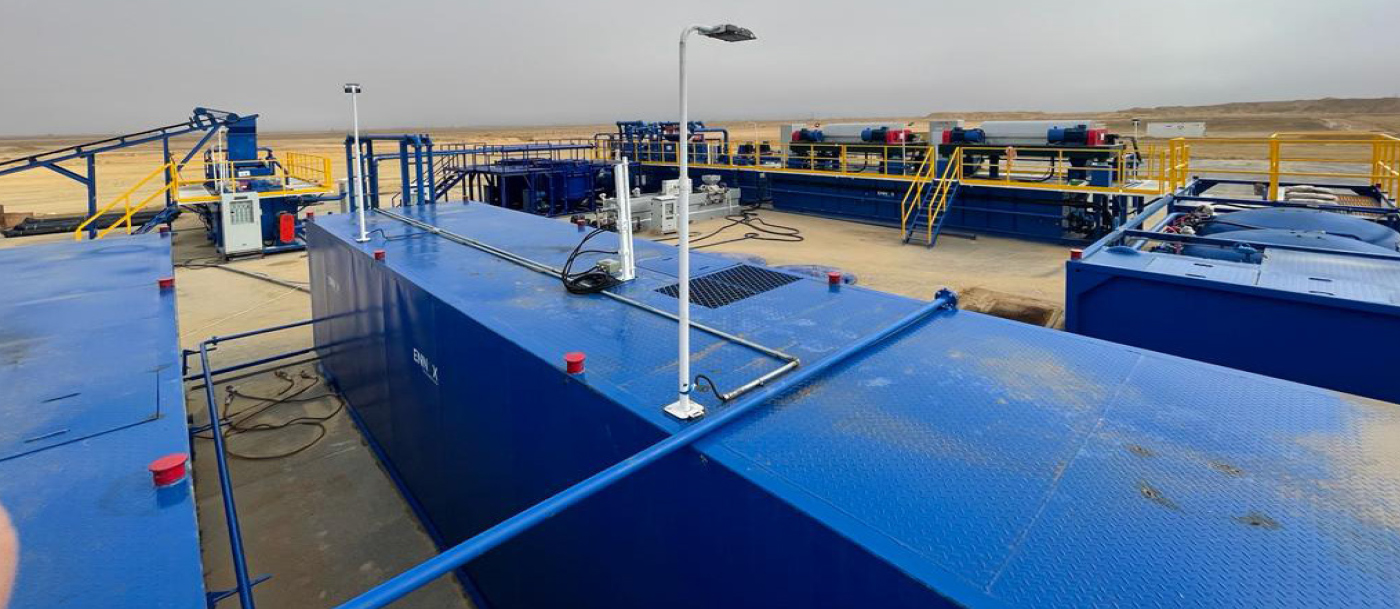

Karazhanbasmunay JSC faced the problem of water shortage due to lack of fresh water sources in the area of Karazhanbas field and large volumes of water required for steam generation to be used as a thermal method of oil reservoir treatment by reinjection. As a consequence, there was a threat of drop in oil production and associated losses.

Since September 2019, construction and installation of the desalination plant have been underway at Karazhanbasmunay JSC in Mangystau Region of Kazakhstan. It is at the stage of completion. The desalination plant is designed to treat and utilise the formation water and supply technical water in order to increase the reservoir recovery at Karazhanbas field by steam injection into the reservoir.

The plant is important to the company because in addition to desalination of water for steam generation, it will resolve the issues of sustainable utilisation of produced water. This will improve the field’s reservoir pressure maintenance capabilities.

CDP reporting expanded in 2020, and in 2021 water management data was published for the second time on the CDP website in 2020 Water Security Questionnaire.

More detailed information can be found in KMG’s published reports, which are publicly available at: CDP 2020 Water Security Questionnaire

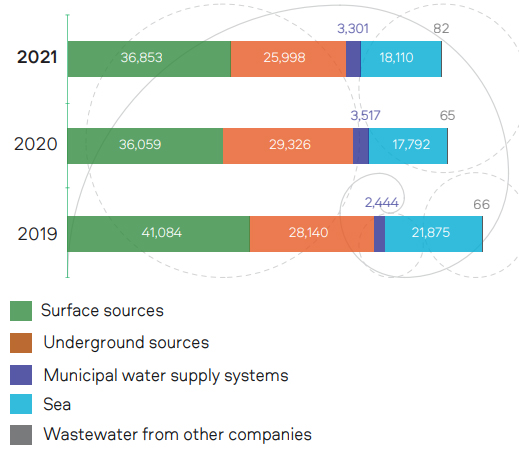

Water Footprint

Water intake by KMG Group in 2021 amounted to 84.34 mln m3, including surface sources – 36.85 mln m3, groundwater sources – 25.99 mln m3, urban water supply systems – 3.30 mln m3, sea – 18.11 mln m3, waste water from other facilities – 0.08 mln m3.

In 2021, 13.59 mln m3 of wastewater was removed by KMG Group. After wastewater treatment at treatment facilities, the standard-quality treated water is discharged to dedicated collectors: gathering ponds, evaporation and filtration fields. Facilities that have no own collectors have their wastewater treated and discharged by dedicated companies under contracts.

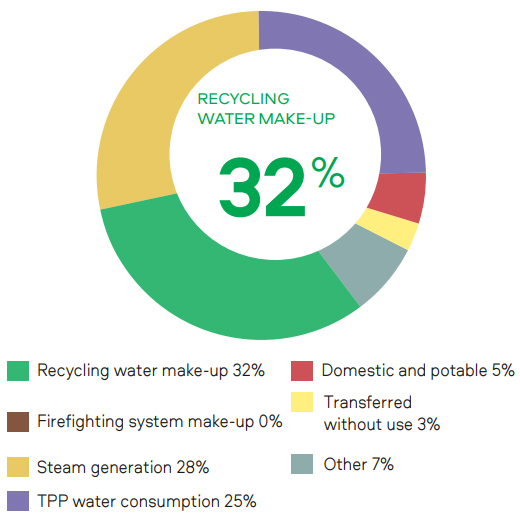

Treated wastewater is reused to wash vehicles, suppress dust and make up firefighting systems. Considerable portion of treated wastewater is only reused by refineries, which reused 3.97 mln m3 of treated wastewater in 2021. The water was mainly used to make up recycling water supply units. KMG plants reused 24% of water (of water intake for oil refining).

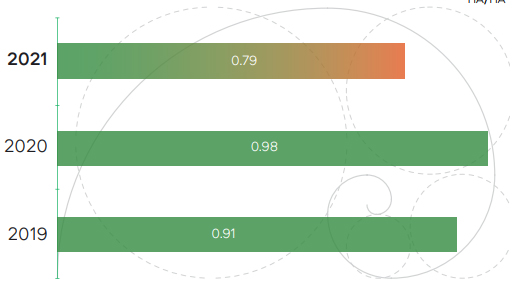

In 2021, recycling water supply systems of KMG refineries used (recycled) a total of 389.99 mln m3 of water.

WATER INTAKE FOR KMG GROUP BY SOURCE, 84,344 THOUSAND M3

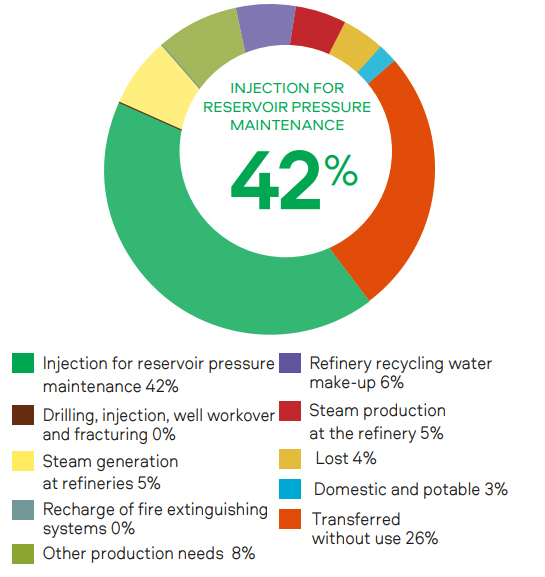

WATER USE BY TYPE OF OPERATIONS WITHIN KMG GROUP IN 2021

Circulating water supply systems of KMG refineries contained

|

|

2019 |

2020 |

2021 |

|

Recycling water, mln m3 |

424.18 |

430.62 |

389.99 |

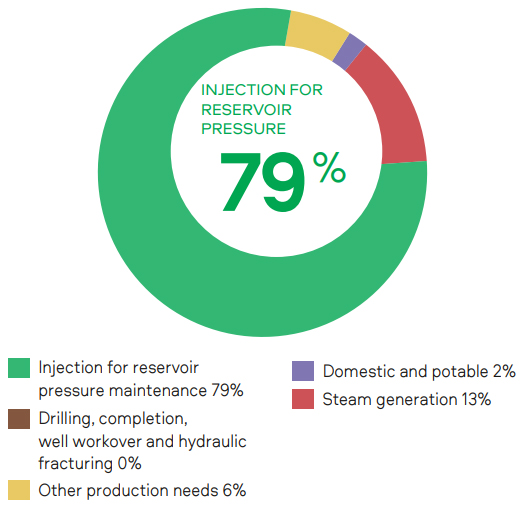

Oil production generates large volumes of so-called associated formation water: water-oil emulsion is brought to surface, which is then separated into water and oil by gravity. After settling in this manner, water is injected into the reservoir.

Out of 131.05 mln m3 of produced associated formation water in 2021, 99% was reinjected to maintain reservoir pressure.

Reinjected to maintain reservoir pressure

|

|

2019 |

2020 |

2021 |

|

Produced associated formation water, mln m3 |

129.19 |

125.37 |

131.05 |

The Company has a considerable impact on water bodies in the West Kazakhstan (Ural River, Kigach River, Kokzhide Sands), which have special environmental, economical, historical and cultural, and recreational value. Regular environmental monitoring is conducted by regulatory authorities to prevent adverse impact on susceptible ecosystems.

WATER USE BY TYPE OF DOWNSTREAM OPERATIONS IN 2021, 16.14 MLN М3

WATER USE BY TYPE OF UPSTREAM OPERATIONS IN 2021, 45.06 MLN М3

Waste Management and Land Reclamation

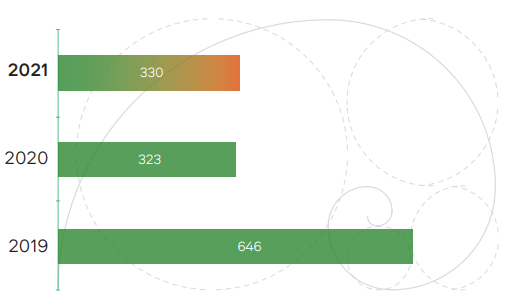

Production and consumption waste is generated during KMG’s operations. KMG Group develops and implements a set of measures aimed at improving the waste management system, keeps records of generated and accumulated waste, including waste of contracting companies, ensures safe accumulation of waste until recovery or disposal, in 2021 KMG spent 12.9 bln tenge on recovery of generated and accumulated waste.

All KMG facilities keep records of production and consumption waste by type, quantity and properties, develop hazardous waste certificates, and keep records of production and consumption waste in a relevant waste register as the waste is generated and transferred for recycling or disposal. The results of waste accounting are submitted to the environmental authority in the form of the following documents: production environmental control reports (quarterly), waste inventory reports (annually), hazardous waste certificates.

On 6 August 2019, a Memorandum of Cooperation was signed between the Ministry of Environment, Geology and Natural Resources of the Republic of Kazakhstan and KMG with commitments to dispose of historic oil waste and clean-up the oil-contaminated land up to and including 2024, with MMG, OMG and KBM included in the memorandum.

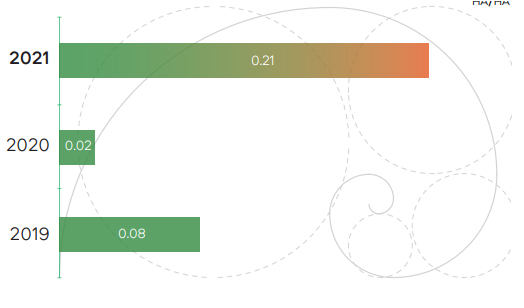

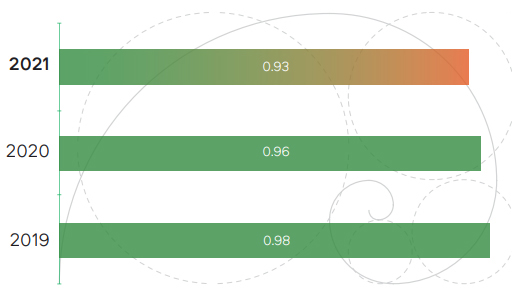

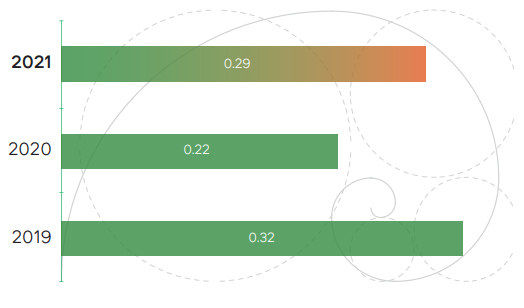

RATIO OF CONTAMINATED LAND AREA AT THE END AND BEGINNING OF YEARHА/HА

RATIO OF RECLAIMED LAND AREA DURING THE YEAR TO CONTAMINATED LAND AREA DURING THE YEAR HА/HА

RATIO OF DISPOSED WASTE AMOUNT TO NEWLY GENERATED WASTE AMOUNT Т/Т

RATIO OF DISPOSED WASTE AMOUNT TO ACCUMULATED AND NEWLY GENERATED WASTE AMOUNTТ/Т

To implement the Memorandum, inventory of MMG, OMG and KBM’s contract areas have been taken since September 2019 to identify waste properties, oil product content in the waste and volumes of waste. Based on the completed inventory, relevant reclamation projects for oil-contaminated land were developed and agreed with the Government Authorities, safe and efficient techniques for oily waste disposal were selected and recommended in the projects, and oil-contaminated land reclamation schedules until the end of 2024 were developed.

In addition, although EMG and KTM are not part of the Memorandum, elimination of historic contamination is also being carried out here.

For all the companies listed above, long-term contracts have been concluded with dedicated companies for disposal of historic oily waste and clean-up of oil-contaminated land, oil waste disposal facilities have been built, and appropriate positive conclusions, permits and licences have been obtained.

In 2021, 540.48 thous. tonnes of historic waste was disposed at the facilities of KMG SDEs, and their disposal sites were reclaimed.

MMG, OMG and KBM plan to complete all disposal of historic contamination by the end of 2024, EMG and KTM plan to complete clean-up of historic oil-contaminated land within the contract areas by the end of 2022.

KTO has fully reclaimed the historically contaminated lands in 984-985 km sections of the Uzen – Atyrau – Samara trunk oil pipeline.

The total mass of waste handled in KMG Group in 2021 was 1,032.0 thous. tonnes, including waste classified as “hazardous” – 964.2 thous. tonnes, and “non-hazardous” – 67.8 thous. tonnes.

Newly generated waste was 413.1 tonnes, of which 93% was disposed or recycled.

KTG Group generated 3.7 thous. tonnes in 2021, of which 2.3 thous. tonnes were “hazardous” and 1.4 thous. tonnes were “non-hazardous”.

KTG Group generated 3.0 thous. tonnes for 10 months of 2021, of which 2.0 thous. tonnes were “hazardous” and 1.0 thous. tonnes were “non-hazardous”.

It is important to note when selecting waste recovery methods, the priority is given to modern waste recovery techniques, including those without secondary contamination of the environment.

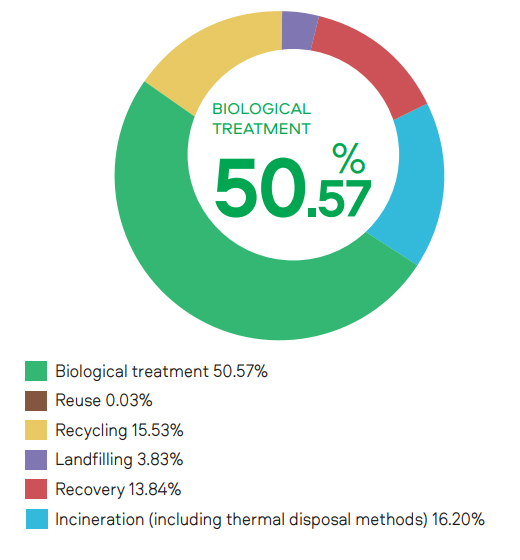

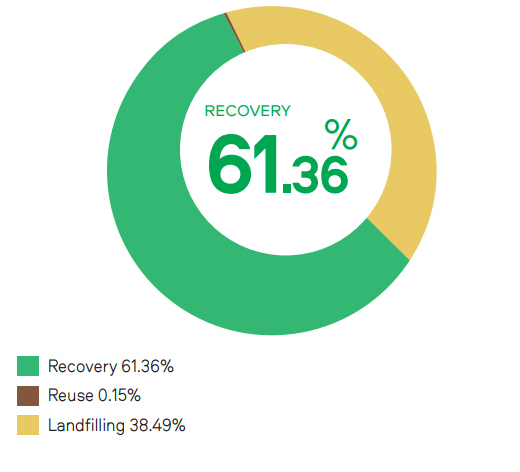

50.57% of waste was biologically recovered, 16.2% of waste was thermally disposed, other significant waste management options are recycling, recovery, burial and reuse.

Dedicated contractors engaged to carry out waste management or disposal are monitored at SDE facilities; engaged contractors have the necessary permits in accordance with RoK laws; contractors’ waste management activities are monitored for compliance, contractors’ facilities are visited, documents confirming the work completion are checked, and control is exercised during the work on requests or under work schedule.

HAZARDOUS WASTE FOR 2021 BY HANDLING TYPE

NON-HAZARDOUS WASTE FOR 2021 BY HANDLING TYPE

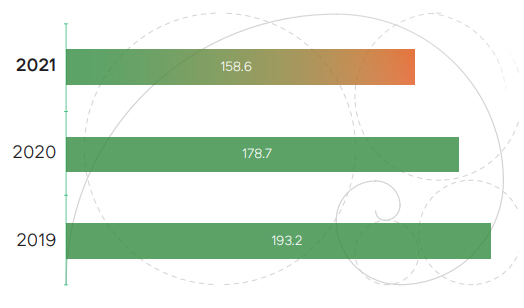

Generation of Drilling Waste

KMG’s production companies generated 158.6 thous. tonnes of drilling waste in 2021, of which: 33.7 thous. tonnes are waste drilling mud, 124.9 thous. tonnes are drilling cuttings (onshore drilling). For disposal purposes, all drilling waste from KMG Group’s production companies is handed over to dedicated companies. The companies further dispose of waste by thermal and chemical methods, inertisation and biological treatment.

OVERALL GENERATION OF DRILLING WASTE ACROSS KMG THOUS. TONNES

Decommissioning and Reclamation of Work Sites

In accordance with laws and regulations, KMG has legal obligations under certain contracts to dismantle and dispose of fixed assets and restore the land at each of the fields. In particular, KMG’s obligations include the gradual shut-in of all unproductive wells and final shutting down of operations, such as the removal of pipelines, buildings and reclamation of the contract area, as well as decommissioning and environmental liabilities at the production site.

The Company calculates asset disposal liabilities separately for each contract. As of 31 December 2021, oil and gas asset disposal liabilities amounted to 67 bln tenge (as of 31 December 2020: 66 bln tenge). Reclamation and disposal processes for contract areas are governed by Subsoil and Subsoil Use Code of the Republic of Kazakhstan No. 125-VI ZRK dated 27 December 2017.

According to the Subsoil and Subsoil Use Code of the Republic of Kazakhstan:

- Subsoil use remediation shall be performed in accordance with the subsoil use remediation project approved by the subsoil user and having positive expert review opinions as stipulated by this Code and other laws of the Republic of Kazakhstan.

- Subsoil area preservation shall be performed in accordance with the subsoil area preservation project approved by the subsoil user and having positive expert review opinions as stipulated by this Code and other laws of the Republic of Kazakhstan.

- Process facilities shall be decommissioned or preserved in accordance with the process facility decommissioning or preservation project approved by the subsoil user and having positive expert review opinions as stipulated by this Code and other laws of the Republic of Kazakhstan, except for certain categories of wells specified in the rules for preservation and decommissioning during exploration and production of hydrocarbons, approved by the hydrocarbons authority, with respect to which the preservation and decommissioning is performed in accordance with the preservation and decommissioning plan.

Well abandonment requirements are specified in the Rules for Sealing and Abandonment during exploration and production of hydrocarbons and uranium mining approved by Order No. 200 of the Minister of Energy of the Republic of Kazakhstan dated 22 May 2018. Registered with the RoK Ministry of Justice under No. 17094 on 19 June 2018 (Chapter 4. Abandonment of oil, gas and injection wells for various purposes in hydrocarbon exploration and production).

Trunk Oil and Gas Pipelines

In accordance with the Law of the Republic of Kazakhstan on Trunk Pipeline, which came into force on 4 July 2012, JSC “KazTransOil” has a legal obligation to decommission the trunk pipeline upon termination of operation and then carry out environment remediation measures, including land reclamation. The reserve for pipeline decommissioning and land reclamation obligation is estimated on the basis of the cost of dismantling and reclamation calculated by KMG. As of 31 December 2021, the carrying value of KMG Group’s reserve for pipeline decommissioning and land reclamation obligation amounted to 35 bln tenge (as of 31 December 2020: 114 bln tenge).

OFFSHORE WELL CONTROL

KMG is engaged in geologic exploration works in Abai, Isatai, Zhenis and Al-Farabi areas in the Kazakhstan Sector of the Caspian Sea. Geologic exploration works under these projects is carried out by specially established joint ventures in order to share KMG’s risks and under Subsoil Use Contracts and Joint Operating Agreements signed by the Parties (ENI, Lukoil, etc.). Management decisions on offshore drilling and seismic acquisition in the joint ventures are made by KMG and Partners within the Operating Committees and their subcommittees (financial, technical, HSE, procurement) in full compliance with international standards and RoK laws. All responsibilities relating to offshore well control are set out in the Operating Committee Regulations and Joint Operating Agreement.

In 2021, preparatory works were performed together with LUKOIL PJSC to drill an exploration well in Zhenis area. Zhenis Block is located in the Kazakhstan Sector of the Caspian Sea at depths of 75-100 m. The distance from the block to the port of Aktau is 180 km and the license area is 6,848 sq. km. The main minimum obligations under the signed contract are to drill one exploration well and conduct 3D seismic acquisition. The operator of this project is Zhenis Operating Joint Venture. The new project in the Caspian Sea is an important step in expanding resource base in a region that is strategic for the Company and has significant accumulated expertise. The first exploration well is scheduled to be drilled in Zhenis area in 2022.

Oil Spill Prevention and Response

Continuous preparedness for emergency oil spill response (hereinafter, EOSR) is an absolute priority for us.

The Caspian Sea is a unique natural water body which fragile ecosystem is particularly sensitive to oil pollution due to its enclosed nature. We have high requirements for environmental safety of offshore oil operations: before commencing any work, we conduct baseline environmental surveys in contract areas and assess our potential social and environmental impacts, as well as impact monitoring, emission monitoring and emergency monitoring – during and after operations.

Prior to offshore drilling operations, we ensure that we are always prepared to respond to all possible emergency oil spills. Once the work is completed, we conduct continuous environmental monitoring of abandoned wells. Monitoring of abandoned wells in the contract areas includes observation of air quality, sea water and bottom sediment pollution, biodiversity status, as well as laboratory testing, photo and video recording of the wellheads of abandoned wells.

In our offshore operations, we strictly adhere to the following principles:

- Strict compliance with design solutions

- Zero discharges principle – all waste and waste water are removed to the shore

- Provision of fish protection devices for all floating crafts, no bilge water

- Operations are prohibited during spawning season from 1 April to 15 July

- Fishing from industrial vessels is prohibited

- Well testing and raw hydrocarbon flaring are prohibited at night

- Observing of special use conditions.

To provide EOSR services, Zhambyl Petroleum LLP entered into a contract with a consortium represented by KMG Systems & Services LLP, Kazmortransflot LLP and the Republican State Enterprise based on the Right of Economic Management “Professional Paramilitary Emergency Rescue Service”. During the appraisal well construction, EOSR vessels stay within 500 metres of the Caspian Explorer SEFDR.

OIL SPILL VOLUMETONNES

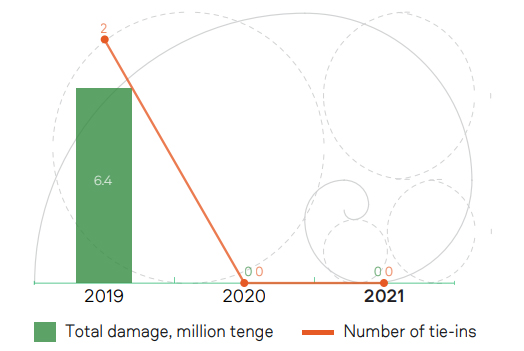

UNAUTHORISED TIE-INS

The main cause of oil spills in the Company is oilfield pipeline ruptures caused by corrosion processes. The Company continues work to reduce the number of oilfield pipeline failures and ruptures by performing timely and high-quality pipeline inspection, reconstruction, replacement, inhibition and cleaning to improve pipeline integrity and reliability.

In close cooperation with law enforcement agencies, JSC “KazTransOil” has overcame the situation with criminal illegal tie-ins into the Company’s pipelines. Over the last 2.5 years, criminal tie-ins into trunk pipelines have been reduced to zero (in 2019, two tie-ins were identified, the damage amounted to 3.7 mln tenge; in 2020 and 2021, no criminal tie-ins were detected).

This has been achieved largely as a result of the following measures:

- Strengthening the monitoring of mobile teams using GPS systems and timely rounds and inspections of oil pipelines by mobile teams;

- Oil pipeline protection by means of Optosense monitoring system.

Continuous preparedness for emergency oil spill response (EOSR) is an absolute priority for us.

Initiative to Develop Volunteering in Emergency Oil Spill Response

Considering how serious and important the volunteering is for EOSR, KMG Systems&Services LLP initiated development and implementation of EOSR Volunteering Development Programme in Atyrau and Mangystau Regions (hereinafter, the Programme). The Programme includes all volunteering aspects such as legal aspects of volunteering in the Republic of Kazakhstan and other countries, how to engage volunteers, how to register and manage volunteers before and during EOSR, it also classifies volunteers and tasks suitable for volunteers, rights and obligations of volunteers and basic personal safety for volunteers. The Programme shows the tasks to be addressed before the spill (preparation stage) and tasks in case of oil spill (operation stage).

The main goal of the project is to transfer the knowledge and train volunteers in the basics of EOSR and wildlife rescue.

As part of the project, a training video course was prepared about Transferring of Basic Knowledge on Wild Animals Rescue during Emergency Oil Spill Response Operations (https://youtu.be/P1ru9py2vVs). The target audience for the training video course is both potential volunteers for EOSR and other stakeholders, including government representatives, specialists from offshore oil companies, etc.

The video course will teach you about volunteer’s personal safety, volunteer’s rights and responsibilities, the impact of oil spills on wildlife, and what kind of work volunteers can do in wildlife rescue operations. It is important to understand that volunteers may not be involved in all wildlife rescue operations, as special training and experience in such operations is required for safe and effective work. The course shows which types of work a volunteer can do independently and which only under guidance of experts.

Anyone interested can fill in an application form on the corporate website of KMG Systems&Services LLP for a further 2-day training in Atyrau and Aktau in the basics of oil spill response and impacts.

Biodiversity Conservation and Support of Specially Protected Natural Areas

Protected Natural Areas within Our Footprint and Affected Species of Flora and Fauna

North Caspian is the most productive part of the Caspian Sea. This part of the sea is rich with biological resources. The main commercial fish fauna includes 25 species, of which the most valued are sturgeons with 70-80% of their global reserve living in the basin.

Eastern water area of the North Caspian with deltas of Volga (within the RoK) and Ural is a part of the State Conservation Area in the North Caspian Sea. Wetlands of the North Caspian, particularly deltas of Volga, Ural and Emba, and the adjacent coast and the sea area itself are essential for Eurasia and support millions of water birds and semiaquatic birds during nesting, moulting, seasonal migrations and wintering. One of the largest Eurasian flyways, the Siberia – Black Sea – Mediterranean Sea flyway, crosses the North Caspian.

According to the baseline studies, more than 70 bird species (including 5 rare species from the Red Book of Kazakhstan) migrate through open areas of the North-East Caspian 20-60 km away from the shore. Little egret, spoonbills, pelicans, whooper swan, ferruginous duck and great black-headed gull are nesting near the shore. Swamphen, white-tailed eagle and osprey are also observed flying.

Land cenoses are nesting grounds for 5 species from the RoK Red Book. Steppe eagle is the most common one. As for rare birds, avocets, oystercatcher, little egret may be observed in these areas.

The only large marine mammal (pinniped) of the Caspian Sea is Caspian seal (Phoca caspica). It is an endemic mammal species. Seals are spread throughout the Caspian Sea, although they vary in number in the North part depending on season. Seasonal distribution of animals across the sea area is based on three main phases of the annual cycle: reproduction, moulting and feeding. Reproduction grounds are in the North Caspian that freezes in winter. During feeding period from April to September, seals mainly stay in the Middle and South Caspian. In summer, only a few animals (about 30,000) remain in the North Caspian, the majority of population moves to the deeper and colder South Caspian waters. They migrate to the North shallow waters in the late autumn, where water starts to freeze. The majority of population gathers in the North Caspian in October – November.

This area is essential to conserve biodiversity of Kazakhstan and the entire Eurasian continent and it needs to be continuously monitored and timely protected. From the very beginning of its operations in the North Caspian, KMG has focused on protection of environment of the region.

Novinsky State Natural (Faunal) Reserve of republican status was established to create optimal conditions for reproduction of flora and fauna, including species listed in the RoK Red Book. Protection status – reserve.

Zhambyl area is in the northern part of the Caspian Sea. The contract territory is within the Caspian Sea conservation area, and partially within Novinsky Reserve, although industrial sites do not touch the environmentally sensitive areas. This area has restrictions on production operations during the most environmentally sensitive period. During the studies in the water areas, there were no recorded abnormalities in natural conditions, environmental situation or unnatural factors that would cause concerns or increased attention.

Isatai area is in the northern part of the Caspian Sea, 45 km north of the coast of Bozashy Peninsula, in Mangystau Region.

Dead Kultuk (Ustyurt) is the habitat of the most characteristic Caspian species – flamingo, which was common in the north-east in the past, and is still using this part of the sea, moulting and non-breeding locally occurring birds near Komsomolets bay and Dead Kultuk and Kaidak sor. Flamingo (Phoenicopterus roseus) is a locally nesting, decreasing species. It is the only specimen of its species in Kazakhstan fauna. Until now, the main nesting grounds in Kazakhstan included Tengiz lake, Chelkarteniz lake and north-eastern coast of the Caspian Sea.

Komsomolets bay, Dead Kultuk and Kaidak sors are still regularly used by thousands of birds to spend summer and moult. Birds from Central Kazakhstan fly through these areas and enlarge the local non-nesting population in April and August-September. Up to 35 thousand birds migrate through Komsomolets bay each year.

Mangystau Region. Mangystau Region has a vast system of speically protected natural areas including Ustyurt State Nature Reserve and Kenderli-Kayasan Conservation Area of republican status, as well as 8 reserves and 1 natural park of regional subordination. Blotched snake (Elaphe sauromates) is a reptile listed in the Red Book of the Republic of Kazakhstan (2010) and inhabiting Mangystau Region. Afghan tortoise is a common, well spread species that is quite numerous in certain areas of Mangystau Region, nevertheless, according to criteria of the Red List of International Union for Conservation of Nature (IUCN) it is a vulnerable species.

Kenderli-Kayasan Conservation Area of republican status was established to preserve habitat and natural reproduction grounds of houbara bustard and saker falcon. Established status: conservation area, reserve, controlled status.

Ustyurt State Nature Reserve belongs to the highest category of specially protected areas of republican status. Ustyurt State Nature Reserve (USNR) was founded with the main goal of preserving the natural state of unique natural complexes, historical monuments, flora and fauna of Kazakhstan deserts. The Reserve is the main habitat of several species listed in the RoK Red Book and/or International IUCN Red List: goitered gazelle, Ustyurt mountain sheep – urial, caracal, honey badger, golden eagle, Eurasian eagle-owl, white scavenger vulture, houbara bustard, etc. According to the leading experts, the USNR meets the criteria of a UNESCO World Heritage Site and may receive this honorary status in the future, proving the highest international level of its value recognition.

For the first time in the history of observations of Ustyurt GPP, a live fore leopard was discovered in 2018, which was included in the Red Book in 2021. Formerly, the leopard was only known in Kazakhstan because it was killed by human on 3 occasions, including twice in Mangystau Region in 2007 and 2015. Leopards sometimes get to Mangystau from the neighbouring Turkmenistan, and considering the adequate food reserves (mountain sheep and goitered gazelle), they might possibly form here a local population if they were not hunted by human and if the habitats were properly protected. There is at least 600 km between the Ustyurt Reserve to Kopetdag in Turkmenistan, where the leopard is positively known to live.

Over the last decades, certain species of mammals that are new for the region were found: desert long-eared bat in West Ustyurt, lesser mouse-eared bat and common noctule in North Ustyurt, honey badger in South-Western Ustyurt, golden jackal in Mangyshlak plains and Karagiye Depression, raccoon dog. Striped hyena was encountered in West Ustyurt and signs of Indian crested porcupine were observed, which has not been recorded in the area for more than 40 years.

Kokzhide-Kumzhargan State Integrated Nature Reserve of local status. This reserve accommodates two sites of nature reserve fund of republican status: Kokzhide Sands and Kokzhide Groundwater, which are included in the List of Geological Sites of the State Nature Reserve Fund of republican and international status.

Urikhtau, Alibekmola and Kozhasay fields are located in Mugalzhar District of Aktobe Region of the RoK. North-western part of the contract territory of Urikhtau field lays on the Kokzhide Sands, the fields also border the Kozhide−Kumzhargan State Integrated Nature Reserve of local status. To avoid groundwater pollution, environment is being regularly monitored both within the Group operations footprint and near the Kokzhide Sands adjoining the contract territory.

Karazhambas field is in the north-western part of Buzachi Peninsula, within Caspian Depression, in the territory bordering the Caspian Sea on the west. In the west, the field borders the State Nature Conservation Area of the North Caspian Sea. Industrial environmental monitoring includes biannual flora and fauna monitoring.

Production sites within and near the specially protected natural areas

|

Type of SPNA |

Within borders |

Adjacent borders (includes a part of territory) |

Outside borders (located within 1-10 km) |

|

Category IUCN I-IV |

0 |

0 |

Kansu Samtyr |

|

Category IUCN V-VI |

Zhambyl Satpayev Isatay Dead Kultuk (Ustyurt) |

Zhambyl Urikhtau |

Alibekmola Kozhasai Karazhambas Rozhkovskoye |

|

World heritage sites |

– |

– |

– |

|

Ramsar lands |

– |

– |

– |

Our Contribution to Biodiversity Conservation in 2021:

As part of the Environmental Policy, we are committed to:

- not operate in specially protected natural areas of special value as habitats for rare, endangered and valuable animal species, carry out risk assessments when operating in environmentally sensitive areas.

- applying a hierarchy of biodiversity impact mitigation measures when planning and implementing its operations based on four key actions: prevention, minimisation, restoration and compensation of potential significant direct impacts.

- participating in research programmes and industry partnerships to further accumulate knowledge and develop innovative solutions for environmental and biodiversity protection.

- preventing illegal hunting, fishing and other use of flora and fauna by own employees and the employees of contractors and subcontractors in contract areas.

Baseline environmental studies, well drilling and testing took place on the sites within the North Caspian state nature conservation area. There are currently no significant man-caused effects in these regions, which would restrict free movement of wild animals and birds within their habitats. During drilling operations, the following activities have environmental impacts: drilling rig installation, well drilling and testing, navigation. The impact factors are increased concentrations of suspended solids in water during offshore construction, disturbance of natural structure of bottom deposits due to intensive navigation among other things, physical effects of noise.

Industrial environmental monitoring of the environment, abandoned wells and research and development (R&D) in the areas of hydrology, hydrochemistry, hydrobiology and ichthyology are conducted to compensate for unavoidable damage to fish resources caused by operations.

In order to preserve and replenish the biodiversity of the Caspian Sea, Zhenis Operating LLP, together with the Atyrau Sturgeon Hatchery, released 166,210 young sturgeons into the Ural River. The place, time and method of stocking were in line with the scientific recommendations of the Scientific Production Centre of Fisheries of the Republic of Kazakhstan.

Seagoing vessels are designed and built under the supervision of the Classification Society “Russian Maritime Register of Shipping” in accordance with International Convention MARPOL-73/78 (International Convention for Prevention of Pollution from Ships). Vessels are fuelled using systems that prevent spills and fuel leaks. Vessels are provided with equipment preventing the vessel deck against contamination by oil products, discharge of contaminated waste waters into water bodies. Vessels have sea valve grating to prevent entry of fish.

Water is supplied to the refinery facilities for industrial and firefighting purposes from the Ural River by the Water Intake Facility, which is equipped with a new fish protection structure and meets modern environmental requirements. A water jet louvered screen type device is designed to prevent juvenile fish from entering the water intake ports. The device operates throughout the navigation period. During the inter-navigation period, the water intake ports are covered with the available mesh.

Construction of an appraisal well in East Urikhtau field and an appraisal directional well in South Urikhtau field has started in Urikhtau, which borders with specially protected lands. Groundwater impact factor is the well drilling that may contaminate groundwater. Contaminants may also enter groundwater with infiltrating precipitation from the surface of industrial and domestic waste accumulations, oil-contaminated areas, oil and formation water storage areas. In this respect, KMG implements a set of measures to protect groundwater and prevent its contamination, clogging or depletion. Well design isolates groundwater reservoirs by running the casing down to 80-85 meters, and regular observations are performed with regard to occurrence conditions, level and quality of groundwater in areas of current and potential pollution.

Another impact factor of industrial development of the territory on biodiversity is power transmission lines that pose major danger for bird fauna. The network of overhead power lines constantly expands and invades the natural bird habitats, often causing their mass death. This concern is particularly relevant for predatory birds living in forest-free steppes and semi-deserts where overhead line pylons are the most attractive for these birds to sit on.

Areas of high danger for birds on electrical installations are identified and investigated during special investigations or industrial environmental control. Special polymeric bird protection devices (BPD) are installed on overhead power lines (6-10 kV) to prevent bird deaths from electrocution. This type of BPD, although widely used abroad, is only beginning to be used in Kazakhstan. Its advantages lie in the fact that all BPD elements are made of dielectric materials. BPD installation does not require complex preparatory work (welding, drilling of beams, etc.). And the insulation of the current carrying wire eliminates dangerous short-circuits involving birds.

For example, during overhauls of 6-10 kV overhead lines in KTO, the AS-50/8 steel-aluminium wire that has exhausted its standard service life is replaced with SIP-3 self-supporting protected wire. 223 km of SIP-3 wire were installed during overhauls. Use of self-supporting protected wires insulates the bird from exposed live parts, thus protecting the birds from electrocution and death.

In October 2021, KMG experts took part in an online discussion on the topic of “Current Problems of Rare Birds of Prey in the RoK” held by the Association of Environmental Organisations of Kazakhstan. Current topics of biodiversity conservation, bird deaths on power lines, migration of birds, population of rare species, the problem of Lake Small Taldykol were discussed.

|

|

Onshore Operations |

Offshore Operations |

||

|

|

2020 |

2021 |

2020 |

2021 |

|

Areas for which biodiversity is covered by an EIA or similar document (%) |

100 |

100 |

100 |

100 |

|

Areas subject to regular environmental monitoring (%) |

100 |

100 |

100 |

100 |

|

Areas with abandoned wells subject to regular monitoring (%) |

100 |

100 |

100 |

100 |

Each of us can contribute to conservation of biodiversity in our country by following the simple rules:

- Do not litter in the street and natural areas;

- Care for the environment;

- Do not engage in illegal hunting and fishing;

- Focus on conservation of biodiversity when planning environmental activities;

- Report violations of environmental law by legal entities and individuals to authorized officers and to hse@kmg.kz;

- Record the presence of red-book listed animals and plants in an area by taking photos and tagging locations, and send to hse@kmg.kz;

- Participate in campaigns and programmes to preserve biodiversity in Kazakhstan;

- Send your initiatives, ideas and projects to hse@kmg.kz.

Offshore Spill Prevention

Continuous preparedness for emergency oil spill response (EOSR) is an absolute priority for us. The Caspian Sea is a unique natural water body which fragile ecosystem is particularly sensitive to oil pollution due to its enclosed nature. We have high requirements for environmental safety of offshore oil operations: before commencing any work, we conduct baseline environmental surveys in contract areas and assess our potential social and environmental impacts, as well as impact monitoring, emission monitoring and emergency monitoring – during and after operations. Prior to offshore drilling operations, we ensure that we are always prepared to respond to all possible emergency oil spills. Once the work is completed, we conduct continuous environmental monitoring of abandoned wells. Monitoring of abandoned wells in the contract areas includes observation of air quality, sea water and bottom sediment pollution, biodiversity status, as well as laboratory testing, photo and video recording of the wellheads of abandoned wells.

In our offshore operations, we strictly adhere to the following principles:

- Strict compliance with design solutions

- Zero discharges principle – all waste and waste water are removed to the shore

- Provision of fish protection devices for all floating crafts, no bilge water

- Operations are prohibited during spawning season from 1 April to 15 July

- Fishing from industrial vessels is prohibited

- Well testing and raw hydrocarbon flaring are prohibited at night

- Observing of special use conditions.

To provide EOSR services, Zhambyl Petroleum LLP entered into a contract with a consortium represented by KMG Systems & Services LLP, Kazmortransflot LLP and the Republican State Enterprise based on the Right of Economic Management “Professional Paramilitary Emergency Rescue Service”. During the appraisal well construction, EOSR vessels stay within 500 metres of the Caspian Explorer FDR.

On 08 October 2021, KMG Systems & Services LLP (hereinafter, KMGSS), a SDE of KMG, held training for volunteers for potential emergency oil spill response (EOSR) at the Bautino Offshore Operations Support Base (OOSB) in Mangystau Region as part of Kaspiige Qamqorlyq (Caring for the Caspian Sea) Volunteer Campaign initiated by the Company. The training course was attended by 18 volunteers, as well as five staff members of the Mangystau Region Department of Emergency Situations (DES). The training programme includes a theoretical and practical part on the basics of environmental oil contamination response. During training, the volunteers were introduced to EOSR equipment and how it works, learned about spill response techniques, and had the opportunity to handle the equipment themselves, including participating in deploying special booms.

The Kaspiige Qamqorlyq (Caring for the Caspian Sea) volunteer campaign was initiated by the Head of State in 2020 and includes volunteers from among the residents of Atyrau and Mangystau Regions – like-minded people united by the desire to provide voluntary and selfless assistance to preserve the environment and biological resources of their native land.

To this end, KMG SS intends to conduct regular training and recruitment of local university students and local communities as EOSR volunteers, share information, guidance and other literature, arrange venues (rooms/conference halls, etc.) for training, media and PR support for the volunteering, and facilitate the integration of volunteering with stakeholders to enhance and strengthen EOSR cooperation.

Environmental Payments and Costs

To effectively manage environmental risks, the Company is continuously improving its approaches to environmental management and allocates necessary resources for environmental protection.

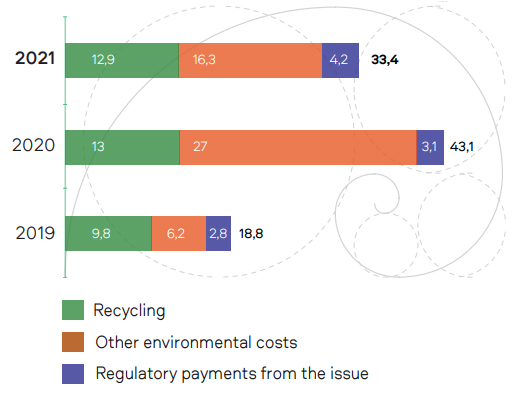

Environmental costs include taxes on permitted emissions, cost of environmental activities, insurance, compensatory environmental measures, investments to prevent environmental impact, etc. We increased the budget for historic waste recycling and contaminated land remediation. Investments in waste recycling tripled since 2015 and make up over a third of all environmental costs. Tax payments for emissions increased in 2021 due to flaring by one of producing SDEs during the test production. Environmental costs in 2021 amounted to 33.4 bln tenge, which is 12 bln tenge more than in 2020. The bulk of costs are from recycling of oil waste, introduction of more environmentally friendly technologies and upgrade of treatment facilities.

Environmental Law Compliance

We are committed to conducting our operations under the laws of the Republic of Kazakhstan and take appropriate measures to prevent any damage to the environment.

The Company will keep on identifying non-compliances with the environmental law of the Republic of Kazakhstan at its production facilities, identifying problems and managing risks in order to take measures for preventing any non-compliances with legislative requirements.

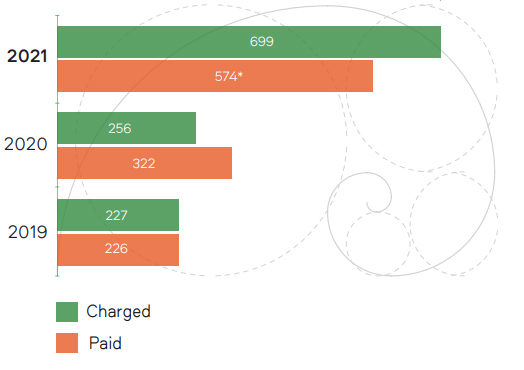

Penalties charged and paid, mln tenge.

This chart shows the amounts of penalties charged and paid.

DYNAMICS OF ENVIRONMENTAL PAYMENTS AND COSTS AT KMG GROUP OF COMPANIESBLN TENGE

ENVIRONMENTAL PENALTIESMLN TENGE

*In December 2021, Kazakhoil Aktobe LLP was charged for damages amounting to 5.9 bln tenge, which KOA declines. An appeal has been initiated

Note: Environmental penalties to KTG for 10 months of 2021 amounted to 29 mln tenge, of which 29 mln tenge have been paid.