ENVIRONMENTAL RESPONSIBILITY

Principle 7: Businesses should support a precautionary approach to environmental challenges.

Principle 8: Businesses should undertake initiatives to promote greater environmental responsibility.

Principle 9: Businesses should encourage the development and diffusion of environmentally friendly technologies.

Climate Change and Low-Carbon Development

NC KazMunayGas JSC recognizes that climate change is one of the most significant global challenges impacting ecosystems, the economy, and social development. In alignment with global and national strategies to reduce greenhouse gas emissions and achieve carbon neutrality, the Company integrates climate considerations into its development strategy and risk management system.

KMG’s climate strategy is focused on reducing its carbon footprint, improving energy efficiency, and developing low-carbon technologies, as outlined in the Low-Carbon Development Program to 2060 (LCDP-2060), approved by the Board of Directors in 2024. This document outlines the key stages and mechanisms of business decarbonization, including the development of renewable energy sources (RES), implementation of energy-saving technologies, methane emissions management, and carbon capture, utilization, and storage (CCUS) projects.

The Company adopts a comprehensive approach to climate risk management that includes:

- Strategic integration of climate agendas into corporate governance and decision-making processes;

- Systematic identification and assessment of climate-related risks as part of the corporate risk management system;

- Development of adaptation mechanisms to physical and transition climate risks, including strengthening infrastructure resilience and accounting for carbon regulation;

- Transparency and monitoring – regular disclosure of GHG emissions data.

KMG also places strong emphasis on collaboration with international partners, government agencies, and stakeholders to advance low-carbon initiatives. In 2024, the Company joined the Oil and Gas Methane Partnership (OGMP 2.0), contributing to more accurate methane emissions accounting and the adoption of global best practices.

KMG’s commitment to low-carbon development and responsible climate risk management enhances its resilience during the global energy transition, maintaining its leadership in Kazakhstan’s oil and gas sector.

Greenhouse Gas Emission Reduction Targets

In line with the LCDP-2060, the Company has established clear emission reduction and low-carbon technology development targets.

The base year for measuring GHG emission trends is 2019, which represents typical pre-COVID-19 operations and is considered the most representative for tracking progress.

Targets for 2031:

- Reduce direct (Scope 1) and indirect (Scope 2) emissions by 15 % from 2019 levels;

- Reduce methane emissions by 32 %;

- Reduce carbon intensity by 15 %;

- Achieve a 15 % share of RES in electricity consumption;

- Eliminate routine flaring of associated gas;

- Implement a forest-climate offset project covering 1,600 hectares;

- Deploy carbon capture, utilization, and storage (CCUS) technologies.

Targets for 2060:

- Reduce Scope 1 and Scope 2 emissions by 64 %, including offsets;

- Reduce methane emissions by 96 %;

- Reduce carbon intensity by 60 %;

- Reach a 50 % share of RES in electricity consumption;

- Implement forest-climate offset projects covering 11,600 hectares;

- Inject 421 thousand tonnes of CO2 via CCUS projects;

- Produce 1.4 million tonnes of sustainable aviation fuel (SAF);

- Achieve an “A” rating in the CDP Climate score.

These targets ensure a long-term reduction of the carbon footprint, laying the foundation for a gradual transition to a low-carbon economy.

Disclosure According to TCFD Recommendations

|

Component |

TCFD Recommendation |

Disclosed Information |

Report Section |

|---|---|---|---|

|

Governance |

Description of the Board’s oversight of climate-related risks and opportunities |

Description of governance mechanisms for climate issues at the Board level |

Governance of Climate Risks |

|

Description of management’s role in assessing and managing climate-related risks and opportunities |

Management’s involvement in developing and implementing the climate strategy |

|

|

|

Strategy |

Identification of climate-related risks and opportunities over the short, medium, and long term |

Key climate risks and opportunities and their potential impacts on company operations |

Climate Risk Assessment |

|

Impact of climate-related risks and opportunities on the business, strategy, and financial planning |

Description of adaptation of strategy and business processes to climate challenges |

Climate Risk Management Strategy Key projects under the climate strategy |

|

|

Resilience of the company’s strategy under different climate scenarios |

Climate scenario analysis and its implications for the company |

Climate Risk Management Strategy Climate Risk Assessment |

|

|

Risk Management |

Processes for identifying and assessing climate-related risks |

Approaches to identifying, assessing, and monitoring climate-related risks |

Climate Risk Assessment |

|

Processes for managing climate-related risks |

Measures for mitigation and adaptation to climate risks |

|

|

|

Integration of climate risks into the overall risk management system |

Incorporation of climate risk management into corporate risk governance |

Integration of Climate Risks into Risk Management |

|

|

Metrics and Targets |

Metrics used to assess climate-related risks and opportunities |

Key climate metrics such as greenhouse gas emissions and energy efficiency |

Greenhouse Gas Emissions Energy efficiency and conservation programs |

|

Scope 1, 2 (and if applicable, Scope 3) greenhouse gas emissions |

Detailed disclosure of emissions data |

Greenhouse Gas Emissions |

|

|

Targets set by the organization related to climate issues |

Long-term and mid-term emission reduction and climate resilience targets |

Greenhouse Gas Emission Reduction Targets |

Climate Risk Management

NC KazMunayGas JSC applies a comprehensive and systematic approach to climate risk management, aligning with leading international practices, including the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD). The Company views climate risks as strategically significant factors that may impact operational activities, investment decisions, and the long-term resilience of the business.

Role of Management in Climate Risk Management

The KMG Board of Directors exercises the highest level of oversight over the Company’s climate policy, approves key strategic documents such as the Low-Carbon Development Program to 2060 (LCDP-2060), and monitors the implementation of climate-related initiatives. For in-depth review of environmental, climate, and ESG issues, the Health, Safety, Environment and Sustainable Development Committee (HSE&SD Committee) operates under the Board and regularly analyzes current and emerging climate risks and opportunities.

The Company’s Management Board is responsible for integrating climate aspects into strategic and operational management. Within KMG’s management structure, designated executives oversee climate initiatives, including the Deputy Chairman of the Management Board, who coordinates implementation efforts, and heads of relevant departments responsible for emissions monitoring, carbon asset management, and low-carbon technology deployment.

The Department of Low-Carbon Development plays a key role in implementing the climate strategy. It is responsible for developing and monitoring decarbonization roadmaps, coordinating efforts with subsidiaries and affiliates, and promoting initiatives in renewable energy and carbon capture.

In 2024, the Company also approved several new regulatory documents that reinforce its climate policy and emissions management framework, including the Methodology for Monitoring and Reporting Greenhouse Gas Emissions and the Methane Emissions Management Instruction. These documents formalize KMG’s commitment to reducing its carbon footprint and establish a unified approach to managing climate-related factors across the Group.

Integration of Climate Risks into the Risk Management System

Climate risks are integrated into KMG’s Corporate Risk Management System (CRMS), enabling the Company to identify, assess, and mitigate the potential impacts of climate change in a timely manner.

Under this approach, the Company:

- Identifies physical and transition climate risks, taking into account various climate scenarios;

- Develops risk maps and management plans, including adaptation measures and mitigation of climate impacts;

- Conducts regular monitoring of climate risks and includes them in the Company’s Risk Register and Risk Map, as well as in annual reporting.

To manage identified risks, KMG develops adaptation strategies, including improving energy efficiency of its assets, expanding renewable energy, deploying carbon capture, utilization and storage (CCUS) technologies, and reducing methane emissions.

Transparency and disclosure play a key role in KMG’s approach to climate risk management. The Company regularly discloses information on climate risks and its carbon footprint in accordance with international standards, including TCFD, GRI Standards, CDP, and ISO 14064.

By integrating climate aspects into corporate governance and risk management, KMG strengthens its resilience to climate challenges and enhances its competitiveness in the energy transition era.

Climate Risk Management Strategy

The Company implements the Low-Carbon Development Program to 2060 (LCDP-2060), which outlines the key priorities, focus areas, and instruments for reducing its carbon footprint.

The main elements of the strategy include:

- Integrating climate-related considerations into business processes, including investment decisions, production operations, and risk management;

- Gradually reducing greenhouse gas (GHG) emissions and transitioning to a low-carbon economy using advanced technologies and international standards;

- Expanding renewable energy, implementing energy efficiency solutions, and reducing methane leaks;

- Applying CCUS mechanisms and implementing forest-climate offset projects;

- Systematic monitoring and reporting aligned with international standards.

KMG’s strategy aims at long-term climate risk reduction and creating opportunities for sustainable development, considering global trends and Kazakhstan’s national commitments to achieve carbon neutrality by 2060.

Time Horizons

The Company has defined three time horizons for climate-related planning:

- Short-term (0–1 year): Includes annual budgeting and operational planning, analysis of current risks and opportunities;

- Medium-term (1–10 years): Aligns with KMG Group’s Development Plan and business plans of subsidiaries and affiliates, considering Kazakhstan’s Nationally Determined Contributions (NDCs) to global climate initiatives;

- Long-term (10–35 years): Covers the Company’s strategic goals, including LCDP-2060 implementation, development of low-carbon projects, and alignment with international decarbonization standards. It also reflects the goals and principles of the Republic of Kazakhstan’s Carbon Neutrality Strategy to 2060.

Decarbonization Scenarios

As part of its climate strategy, KMG applies various scenarios to assess potential development pathways and adaptation to changing conditions. These scenarios help forecast the impact of climate risks and determine optimal response measures.

1. Realistic Scenario

Assumes a reduction in carbon footprint through:

- Implementation of energy efficiency and energy saving measures at production facilities;

- Deployment of two large-scale renewable energy projects with a total capacity of 1.2 GW in the Mangystau and Zhambyl regions.

2. Green Development Scenario

This scenario is aimed at achieving decarbonization targets and includes:

- Implementation of energy efficiency measures;

- Increasing the share of renewable energy in the energy mix sufficient to meet the Company’s climate targets;

- Implementation of a forest-climate offset project to compensate part of the greenhouse gas emissions.

Under this scenario, KMG focuses on two key approaches to reducing greenhouse gas emissions:

- Organic emission reductions achieved through improved operational efficiency and modernization of production assets, considering potential changes in production volumes;

- Inorganic emission reductions through the implementation of new technological solutions at the corporate level, including the construction of renewable energy facilities and the purchase of renewable electricity for industrial needs, allocated among the Company’s enterprises via intragroup agreements.

3. Deep Decarbonization Scenario

Envisions a 64 % reduction in greenhouse gas emissions from 2019 levels by:

- Large-scale deployment of carbon capture, utilization, and storage (CCUS) technologies;

- Active offset policy, including forest-climate projects and development of hydrogen energy.

KMG plans to define its carbon neutrality targets by 2030 following pilot testing of these directions.

These scenarios enable KMG to respond flexibly to changes in regulation, economic trends, and technological advancements, ensuring sustainable business development and compliance with climate commitments.

Climate Risk Assessment

Approach to Climate Risk Assessment (Scenario Analysis)

KMG applies two main approaches for analyzing climate risks:

- Analysis of physical climate risks related to changes in the natural environment and their impact on the Company’s operations;

- Assessment of transition risks associated with economic transformation, regulatory developments, and market demand shifts during the global energy transition.

When evaluating physical risks, KMG uses Representative Concentration Pathways (RCPs) developed by the Intergovernmental Panel on Climate Change (IPCC):

- RCP 2.6 – a low-emission scenario where global temperatures stabilize due to strict climate policies;

- RCP 4.5 – a medium pathway assuming moderate mitigation efforts;

- RCP 8.5 – a high-emission scenario with no significant measures to limit emissions.

To assess transition risks, KMG uses scenarios developed by the Network for Greening the Financial System (NGFS):

- Nationally determined contributions (NDC) – assumes all announced policy measures are implemented, even if not yet enacted;

- “Below 2°C” Scenario – a moderate transition path that gradually strengthens climate policy to keep warming below 2°C;

- Delayed Transition Scenario – assumes delayed action until 2030, requiring abrupt and more drastic measures thereafter;

- Net Zero by 2050 Scenario – an ambitious path where strong policy and technological innovation achieve carbon neutrality.

Based on these scenarios, KMG conducts climate risk assessments at both the corporate and asset levels, allowing for the development of effective adaptation strategies.

Key Climate Risks and Mitigation Measures

|

Physical Climate Risks |

Planned and Ongoing Mitigation Measures |

|

Sharp changes in temperature conditions Potential consequences:

|

|

|

Extreme weather events (floods, hurricanes, storms, dust storms) Potential consequences:

|

|

|

Drought and water shortages Potential consequences:

|

|

|

Transition Climate Risks |

Planned and Ongoing Mitigation Measures |

|

Tightening greenhouse gas emission regulations Potential consequences:

|

|

|

Declining demand for oil and petroleum products Potential consequences:

|

|

|

Rising raw material and energy prices Potential consequences:

|

|

|

Lack of regulatory framework for low-carbon projects Potential consequences:

|

|

Key Projects Within the Climate Strategy

1. Enhancing Energy Efficiency and Reducing Emissions

One of the key decarbonization areas is the reduction of direct emissions (Scope 1) through improved operational efficiency and the implementation of energy-saving technologies.

Work completed in 2024:

- 70 activities were implemented under the Low-Carbon Development Plan;

- Annual savings of fuel and energy resources amounted to 2.36 million GJ, equivalent to a reduction of 174.9 thousand tonnes of CO2 emissions;

- Energy consumption at production facilities was optimized through equipment upgrades and automation of technological processes.

2. Development of Renewable Energy

KMG is implementing large-scale renewable energy projects (RES) to replace traditional carbon-intensive energy sources and increase the share of clean energy in the energy mix.

Key projects:

- Construction of a 1 GW wind power plant with an energy storage system (Zhambyl region) – partner: Total Eren, implementation period: 2023–2027;

- 247 MW hybrid renewable power plant in Zhanaozen (Mangystau region) – partner: Eni S.p.A, implementation period: 2023–2026.

Work completed in 2024:

- Feasibility studies for the projects were completed;

- Wind potential in the Zhambyl region was assessed;

- Work is underway to select the main equipment supplier for the wind power plant;

- In December 2024, early works were completed at the solar power plant site, and installation of major equipment began.

3. Carbon Capture, Utilization, and Storage (CCUS)

KMG considers carbon capture and storage (CCUS) a key tool for reducing CO2 emissions and enhancing oil recovery at fields. After 2040, a full-scale CCUS project is planned, with an estimated annual injection volume of up to 412 thousand tonnes of CO2.

Work completed in 2024:

- CO2 emissions screening was completed in the Atyrau and Mangystau regions – key emission sources totaling 412 thousand tonnes of CO2 were identified;

- Infrastructure for CO2 utilization was assessed;

- A concept was developed for a pilot CCUS project with a capacity of 10–20 thousand tonnes of CO2 per year at the Prorva group of fields CPF operated by Embamunaigas JSC.

4. Development of Hydrogen Energy

KMG strategically positions itself in the hydrogen production market as a promising low-carbon energy source. Key focus areas include the production of blue hydrogen with carbon capture, the use of renewables for green hydrogen, scientific research, and the development of new storage and transportation technologies.

Work completed in 2024:

- Feasibility studies were conducted for the production of blue hydrogen, low-carbon ammonia, and methanol;

- A Water Resources Atlas was developed to assess the potential for green hydrogen production in western Kazakhstan;

- A pilot project on green hydrogen production and application is underway;

- An analytical calculator was developed to assess the cost of green hydrogen production;

- First laboratory samples of iron and titanium alloys were obtained for the safe storage and transport of hydrogen.

Successful completion of the project will enable NC KazMunayGas JSC to acquire a hydrogen transport technology for both domestic use and international export.

5. Production of Sustainable Aviation Fuel (SAF)

KMG is considering the production of SAF as an alternative to conventional Jet-1 aviation fuel, which would significantly reduce the carbon footprint of the aviation sector.

Work completed in 2024:

- A study on the potential for SAF production in Kazakhstan was completed by ICF SH&E Limited;

- Key export markets were identified, including the European Union;

- Preliminary technological solutions and capacity of the first plant were developed: 40,000 tonnes of SAF per year requiring 72,000 tonnes of bioethanol;

- A feasibility study (FS) is scheduled for 2025.

6. Implementation of Forest-Based Carbon Offset Projects

KMG views forest-climate projects as an effective mechanism to offset CO2 emissions.

Work completed in 2024:

- A project to create a green zone around the city of Pavlodar covering 1,600 hectares is being implemented jointly with Chevron;

- Field research and soil analysis were carried out to assess CO2 absorption potential, and a Working Project for the creation of green plantations was developed and passed the state environmental review.

Six forest-climate projects are planned under the LCPD-2060.

7. Methane Emissions Management

Reducing methane emissions is one of KMG’s top priorities within global climate initiatives.

Work completed in 2024:

- In May 2024, KMG submitted its first methane emissions report under the OGMP 2.0 framework;

- Methodological support for report preparation was provided in cooperation with IFC and Carbon Limits;

- In June 2024, Tetra Tech ES, Inc. conducted a methane measurement campaign at Ozenmunaigas JSC and KazGPZ LLP facilities;

- A series of trainings and seminars on methane leak detection and repair (LDAR) technologies were held for production personnel.

Given Kazakhstan’s accession to the Global Methane Pledge and the expected tightening of methane emissions regulation in the short term, NC KazMunayGas JSC is actively working on inventorying (baseline determination) and reducing methane emissions at its facilities.

Greenhouse Gas Emissions

Approach to Calculation

NC KazMunayGas JSC has adopted a comprehensive approach to the monitoring, accounting, and verification of greenhouse gas (GHG) emissions in accordance with leading international standards. The Company systematically analyzes its direct (Scope 1), indirect (Scope 2), and other material emissions (Scope 3), ensuring transparency and accuracy in its reporting.

Emissions Accounting Methodology

KMG is guided by the following international standards and methodologies:

- ISO 14064 – a standard for greenhouse gas emissions verification;

- GHG Protocol – methodology for calculating Scope 1, 2, and 3 emissions;

- IPCC Guidelines for national greenhouse gas inventories;

- UNFCCC – United Nations Framework Convention on Climate Change;

- Order of the Minister of Ecology and Natural Resources of the Republic of Kazakhstan dated January 17, 2023, No. 9 – National Methodological Guidelines.

The Company has also developed and approved a Methodology for Monitoring and Reporting Greenhouse Gas Emissions, which standardizes emissions accounting processes across the entire KMG Group.

Emissions Inventory

As part of its climate strategy, KMG conducts a greenhouse gas emissions inventory in the following categories:

- Scope 1 (direct emissions) – emissions from fuel combustion at production facilities (oil and gas extraction, processing, transportation);

- Scope 2 (indirect emissions from energy consumption) – emissions associated with the consumption of electricity and thermal energy purchased from third-party suppliers;

- Scope 3 (indirect emissions across the entire value chain) – includes emissions from the use of sold products, transportation, employee business travel, and other sources.

Since 2023, KMG has expanded its Scope 3 reporting to include five key categories:

- Other indirect emissions from energy consumption (electricity transmission losses);

- Emissions from employee business travel;

- Emissions from employee commuting;

- Emissions from transportation and delivery of finished products;

- Emissions from the use of sold goods and services.

Implementation of Internal Carbon Pricing

To account for the impact of climate-related factors on business and to stimulate emissions reduction, KMG is implementing a system of internal carbon pricing (ICP). This mechanism allows the Company to:

- Assess financial risks associated with tightening carbon regulations;

- Reallocate investments from carbon-intensive projects to low-carbon initiatives;

- Determine a “shadow price” for CO2 emissions to evaluate the sustainability of projects.

Since 2022, calculating the carbon footprint and related financial aspects has been a mandatory part of feasibility studies (FS) for new capital projects.

Transparency and Reporting

KMG regularly discloses information on its emissions and climate risks in line with advanced international reporting standards:

- CDP (Carbon Disclosure Project) – reporting on emissions and climate risks;

- GRI (GRI Sustainability Reporting Standards) – sustainability reporting;

- TCFD (Task Force on Climate-related Financial Disclosures) – climate risk disclosure.

The adopted approaches to GHG emissions accounting ensure reliable and accurate reporting, enabling KMG to effectively manage its carbon footprint and adapt to changing climate-related requirements.

Greenhouse Gas Emissions Volume

GRI 305-1GRI 305-2GRI 305-3GRI 305-4GRI 305-5

The volume of direct greenhouse gas emissions (CO2) for 2024 by the Group of Companies of NC KazMunayGas JSC amounted to 7.7 million tonnes of CO2 (9.06 million tonnes of CO2-equivalent)2

2 CO2-equivalent data are presented using the global warming potential (GWP) coefficients from the IPCC Fifth Assessment Report (methane – 28, nitrous oxide – 265).

The calculation includes carbon dioxide (CO2), methane (CH₄), and nitrous oxide (N₂O).

Direct greenhouse gas emissions data are verified by conclusions from independent accredited organizations for each subsidiary.

GHG Emissions Indicators

|

Scope 1. Direct Emissions |

2022 |

2023 |

2024 |

|

|---|---|---|---|---|

|

Breakdown by business activity |

||||

|

Production |

million t CO2 / million t CO2-eq |

2.4/2.8 |

2.33/3.44 |

2.64/3.98 |

|

Processing |

million t CO2 / million t CO2-eq |

5.1/5.2 |

5.01/5.03 |

4.92/4.94 |

|

Transportation |

million t CO2 / million t CO2-eq |

0.1/0.1 |

0.1/0.1 |

0.14/0.14 |

|

Breakdown by countries |

||||

|

Kazakhstan |

million t CO2 / million t CO2-eq |

6.6/7.1 |

6.55/7.68 |

6.99/8.35 |

|

Romania |

million t CO2 / million t CO2-eq |

0.9/0.9 |

0.88/0.88 |

0.69/0.69 |

|

Georgia |

million t CO2 / million t CO2-eq |

0.02/0.02 |

0.02/0.02 |

0.02/0.02 |

|

Breakdown by type of greenhouse gas |

||||

|

CO2 |

million t CO2 |

7.6 |

7.44 |

7.7 |

|

CH4 |

million t CO2-eq |

0.4 |

1.11 |

1.34 |

|

N20 |

million t CO2-eq |

0.1 |

0.1 |

0.02 |

|

Scope 2 Indirect emissions (market-based) |

million t CO2 / million t CO2-eq |

3.2/3.2 |

3.4/3.4 |

3.3/3.3 |

|

Scope 2 Indirect emissions (location-based) |

million t CO2 / million t CO2-eq |

3.3/3.3 |

3.5/3.5 |

3.4/3.4 |

|

Scope 3 Use of sold products |

million t CO2 / million t CO2-eq |

61.6/61.8 |

54.6/54.8 |

59.1/59.2 |

GHG emissions intensity indicators

|

|

Production |

Transportation |

Processing |

||||||

|---|---|---|---|---|---|---|---|---|---|

|

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

2022 |

2023 |

2024 |

|

|

Scope 1 emissions intensity |

|||||||||

|

Scope 1 Emissions Intensity (tonnes of CO2 per KZT million of revenue) |

0.28 |

0.28 |

0.32 |

0.01 |

0.01 |

0.02 |

0.59 |

0.60 |

0.59 |

|

Scope 2 emissions intensity |

|||||||||

|

Scope 2 Emissions Intensity |

- |

- |

0.15 |

- |

- |

0.03 |

- |

- |

0.24 |

|

Scope 2 Emissions Intensity |

- |

- |

0.15 |

- |

- |

0.03 |

- |

- |

0.23 |

Energy Saving and Efficiency Improvement Programs

Energy Efficiency Management

KMG applies energy saving and efficiency improvement principles based on the methodology of the international ISO 50001 standard “Energy Management Systems,” which is recognized as a global best practice for systematic energy use management.

As part of its Low-Carbon Development Program, KMG has approved key internal regulatory documents that ensure a comprehensive approach to managing energy consumption:

- Energy Policy of NC KazMunayGas JSC;

- Regulation on Energy Saving and Energy Efficiency Management within the KMG Group, applicable to subsidiaries, affiliates, and contractor companies.

In addition to these measures, a targeted energy audit of process furnaces and boiler equipment at oil production enterprises was conducted within the KMG Group. Separate regulations on energy saving and efficiency were adopted at the level of individual subsidiaries (KBM, KGM, KOA, KTM, Pavlodar Refinery, PKOP, Caspi Bitum).

Strategic Goals

In 2024, KMG approved the Low-Carbon Development Program through 2060, which outlines the following key strategic priorities in energy efficiency and resource conservation:

- Long-term planning – development of integrated energy efficiency plans across the Group;

- Effective energy management – ensuring transparent management of energy flows based on reliable and measurable data;

- Centralized monitoring – implementation of a unified system for monitoring and managing energy efficiency processes;

- Engagement with government agencies – ongoing cooperation on energy-saving initiatives;

- Replication of best practices – scaling up successful cases throughout the organization;

- Cost optimization – identification and elimination of inefficient expenditures through rational use of resources;

- Profitability improvement – reduction of fuel and energy losses and minimization of inefficient expenses;

- Improved financial performance – enhanced economic efficiency through reduced energy consumption.

These measures are expected to ensure

a sustainable reduction in energy costs, improve operational efficiency, and support the Company’s decarbonization goals.

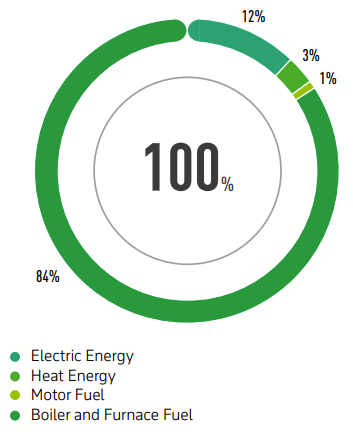

Energy Consumption

In 2024, total fuel and energy resource (FER) consumption across the KMG Group amounted to 129.4 million GJ, a 4 % increase compared to 2023 (124.1 million GJ). The increase in energy consumption was driven by the commissioning of new subsidiaries and dependent entities – Dunga, Urikhtau Operating, Ural Oil and Gas, and KPI.

Breakdown of energy consumption:

- Electricity – 15.1 million GJ

- Thermal energy – 3.9 million GJ

- Motor fuel3– 1.8 million GJ

- Boiler and furnace fuel4 – 108.5 million GJ

In 2024, the Group’s own generation amounted to 737.5 million kWh of electricity and 5,440.6 thousand Gcal of thermal energy.

3 Gasoline, diesel fuel.

4 Furnace fuel, oil, fuel oil, refinery gas, associated petroleum gas, natural gas, defeminized gas, LPG.

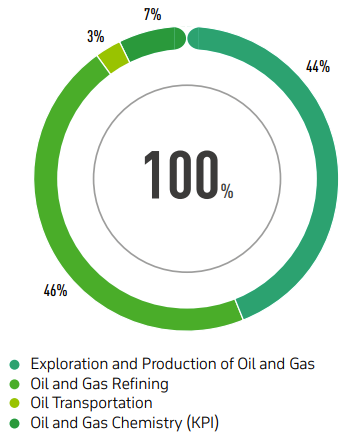

ENERGY CONSUMPTION BY SEGMENTS, THOUSANDS OF GJ

STRUCTURE OF ENERGY CONSUMPTION

As part of support for renewable energy sources (RES), Pavlodar Refinery and MMG purchased 10,832 thousand kWh of electricity produced by RES facilities via the Settlement and Financial Center for RES Support LLP. In addition, PKOP and Caspi Bitum LLP provided street lighting powered by solar panels, generating 149.5 thousand kWh of electricity in 2024.

Energy Consumption Reduction

KazMunayGas is consistently implementing energy efficiency measures aimed at optimizing energy resource consumption and reducing its carbon footprint.

In 2024, the KMG Group implemented 70 equipment modernization initiatives, including:

- Replacement of gas burners in process furnaces;

- Introduction of energy-saving technologies;

- Optimization of heat generation and consumption;

- Modernization of lighting systems.

Economic and environmental outcomes:

- Annual energy savings: 2,361 thousand GJ ;

- Greenhouse gas emissions reduction equivalent: 174.9 thousand tonnes of CO2.

Breakdown of reduced consumption:

- Electricity – 48,114 thousand kWh (173 thousand GJ)

- Thermal energy – 22,334 Gcal (94 thousand GJ)

- Boiler and furnace fuel5 – 21,188 tonnes (887 thousand GJ)

- Dry de-ethanized gas – 5,238 thousand m³ (226 thousand GJ)

- Natural gas – 29,003 thousand m³ (980 thousand GJ)

- Diesel fuel – 36 tonnes (2 thousand GJ)

5 fuel oil, refinery gas

Total investment in energy efficiency measures in 2024 amounted to 5,930 KZT million.

The measures taken not only helped reduce energy consumption, but also improved operational efficiency by reducing costs and minimizing environmental impact.

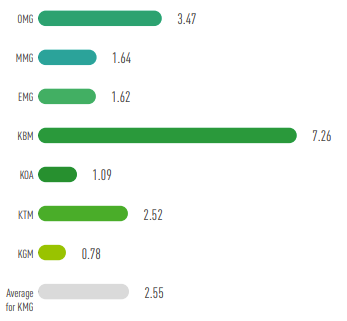

Energy Intensity

In 2024, the specific energy consumption in the hydrocarbon production segment of the KMG Group was 2.55 GJ per tonne of produced hydrocarbons (HC), which is 70 % higher than the global average benchmark of 1.5 GJ/t set by IOGP.

However, the average value for the KMG Group is not fully representative due to significant variations in energy intensity across enterprises. Substantial impact comes from Ozenmunaygas (OMG) and Karazhanbasmunay (KBM), where specific energy consumption significantly exceeds industry norms.

KBM consumes five times more energy than the global IOGP average. This is due to the specific conditions at the Karazhanbas field, where oil is extracted using steam and hot water injection. This method is necessary due to the high paraffin content and unique rheological properties of the oil, requiring heating not only during winter but also in summer.

OMG shows more than double the energy consumption per production unit compared to industry standards. In 2024, the company introduced a well treatment technology using hot oil, which further increased energy consumption.

SPECIFIC ENERGY CONSUMPTION FOR THE PRODUCTION OF 1 TONNE OF HYDROCARBONS (HC), GJ/TONNE

|

GRI-302-3. Specific energy consumption (by segment) |

Units |

2024 |

|---|---|---|

|

Oil & gas exploration and production |

thousand GJ/t of produced hydrocarbons |

2.55 |

|

Oil & gas processing |

thousand GJ/t of processed hydrocarbons |

3.41 |

|

Oil transportation |

thousand GJ/t |

0.09 |