Water Resource Management

Management Approach

In the context of climate change, water resources are becoming increasingly vulnerable, significantly impacting ecosystems, economies, human health, and communities. KMG acknowledges its responsibility for the rational use of water resources and is taking action to reduce its negative impact on aquatic ecosystems.

Strategic Approach to Water Resource Management

KMG’s approach aligns with international sustainable development principles, including SDG 6 (“Clean Water and Sanitation”). The Company is committed to ensuring access to and rational use of water resources, as well as reducing pollution of water bodies.

In line with its Environmental Policy, KMG and its subsidiaries and dependent entities recognize environmental protection and the prevention of negative impacts on water resources as key priorities. The Company is committed to continuously improving water usage processes, including implementing water-saving projects, increasing the share of water recycling, and managing risks related to water scarcity.

To systematize activities in this area, a 10-year Water Resource Management Program has been developed. It focuses on:

- Preventing water resource shortages;

- Protecting ecosystems and reducing environmental impact;

- Improving water use management systems across KMG Group.

The Program covers major operating subsidiaries and includes the assessment of investment projects in terms of water use. As part of the Program, KMG conducted a water footprint assessment, identified key risks, and developed recommendations for their mitigation.

Water Conservation and Rational Water Use

KMG strives to reduce freshwater consumption and increase the volumes of recycled and reused treated wastewater. As part of its corporate water resource management, in 2018 the Company approved a Corporate Water Resource Management Standard based on the “eight water principles.” The Standard regulates water use practices across subsidiaries and helps foster commitment among executives and staff to conserving water resources. An updated version of the Standard is planned for 2025 to reflect the approaches of the Water Resource Management Program.

KMG operates in full compliance with international standards, and Kazakhstan’s environmental and water legislation. The Company has implemented processes for developing pollutant discharge limits and obtaining environmental permits, including those for discharges and water use.

KMG WATER PRINCIPLES

Water is the basis of life, the source of all things existing.

The stability and security of the state is determined by the abundance of clean fresh water, and the success and sustainability of business – by responsible, caring attitude to it. These principles express the Company's commitment and demonstrate its intention to conserve water resources for people, nature and well-being of current and future generations of our country.

We constantly use water - from daily needs to the extraction and processing of oil. And at the same time, within the daily routine, we must not forget how much water is priceless. Every employee of the Company can and should contribute to its preservation.

KazMunayGas NC JSC CEO

Water Use Monitoring and Assessment

The Company ensures transparency in its environmental activities by providing open access to environmental information for shareholders, government agencies, and the public.

Since 2020, KMG has calculated its water footprint and annually discloses water use data via the Carbon Disclosure Project (CDP) water security questionnaire. In 2024, based on its 2023 disclosure, KMG’s water management efforts were rated “B” (up from “C” in 2023).

In 2024, KMG was recognized among the top performers in the first RAEX ESG water efficiency rating. The rating analyzed water use indicators of 144 companies from Russia, Kazakhstan, and Mongolia, assessing not only consumption volumes but also corporate strategies and risk mitigation mechanisms. KMG ranked among the top 10 companies for the most efficient water use.

The Company continues improving water technologies and optimizing water use, which is a key part of its sustainable development strategy.

Environmental and Social Water Use Projects

KMG and its subsidiaries implement a wide range of measures to improve water use efficiency. Key initiatives include modernization of wastewater treatment facilities, development of water infrastructure in regions of operation, and deployment of innovative desalination technologies.

“Tazalyk” Project – Modernization of Atyrau Refinery Wastewater Treatment Facilities

One of the largest environmental projects is the “Tazalyk” Project, implemented by Atyrau Oil Refinery LLP. The goal is to reconstruct evaporation ponds, mechanical and biological treatment units, and build an advanced wastewater treatment facility.

Key environmental outcomes of the project include:

- Improved wastewater treatment quality;

- Elimination of harmful emissions from open reservoirs;

- Reduced environmental impact from evaporation fields.

As part of this project, the capacity of the mechanical treatment facilities is planned to be doubled. Notable achievements include:

- Commissioning of two phases of mechanical treatment plant reconstruction (Phase I – end of 2023, Phase II – May 2024);

- Increased mechanical treatment capacity to 1,000 m³/hour, with oil sludge processing reaching 12,000 m³/month;

- Elimination of open ponds, minimizing hydrocarbon evaporation;

- Completion of pipeline construction to redirect treated water to municipal sewerage, preventing pollutant discharge into the environment.

Ongoing reclamation work on the evaporation fields includes:

- Drainage of sections;

- Reed cutting;

- Deep ploughing and bioremediation;

- A three-stage reclamation process.

Development of Water Infrastructure in Operational Regions

KMG pays special attention to providing water resources to communities in its regions of operation. Two major strategic projects are underway in this area: the reconstruction of the Astrakhan – Mangystau main water pipeline and the construction of a desalination plant in Kenderli.

Reconstruction of the Astrakhan – Mangystau water pipeline aims to increase throughput capacity from 110,000 m³/day to 170,000 m³/day, ensuring water supply to the population, agriculture, industry, and oil and gas facilities in Atyrau and Mangystau regions. The pipeline is a critical water source for Kurmangazy, Isatai, and Zhylyoi districts of Atyrau region, as well as Zhanaozen, Beineu, Mangystau, Karakiya, and Tupkaragan districts of Mangystau region. With annual population water consumption growing by 4–5 %, the project is a crucial step toward regional water security.

Another significant project is the construction of a desalination plant in Kenderli with a capacity of 50,000 m³ per day. The facility will address the shortage of drinking water in Zhanaozen and ensure a stable water supply to support the development of tourism, entrepreneurship, and agriculture in the region.

At present, the main construction works have been completed, including the installation of a 201 km main water pipeline to deliver desalinated water to Zhanaozen, 83 km of power transmission lines, and 40 km of roads.

Work is nearing completion on a 46 km gas pipeline, which is now 97% complete.

The plant is scheduled to be commissioned in 2025, which will significantly improve the quality of life for the local population and support the region’s economic activity.

Innovative Water Treatment and Desalination Technologies

Karazhanbasmunai JSC has implemented a project for a produced water desalination plant at the Karazhanbas field in the Mangystau region. Once operating at full capacity, the plant will allow:

- Treatment of 42.5 thousand m³/day of produced water;

- Production of 17 thousand m³/day of desalinated water;

- Reduction in freshwater withdrawal.

Implementation results to date:

- In 2023, water withdrawal was reduced by 2.6 million m³;

- In 2024, water withdrawal decreased by 4.07 million m³, compared to 6.3 million m³ in 2022.

Water Treatment and Improved Working Conditions

KazTransOil JSC completed a project to install mobile water purification units at the Kalamkas GNPS and Karazhanbas NPS facilities. Project goals include:

- Providing workers with clean drinking water;

- Improving employee working conditions;

- Enhancing social and environmental resilience of production sites.

Previously, these sites relied on drinking water purchased from the Kiyakty village pumping station, which required significant financial resources. Following the installation of the purification units:

- Volga water (technical water) is treated to meet drinking water standards of the Republic of Kazakhstan;

- The Company significantly reduced water supply costs;

- Environmental safety at the sites has been improved.

KMG and its subsidiaries are consistently implementing major infrastructure projects aimed at reducing water intake, improving wastewater treatment quality, and ensuring access to drinking water for the population. The implementation of modern technologies minimizes environmental impact and strengthens water security in the Company’s regions of operation.

WATER FOOTPRINT

WATER WITHDRAWAL

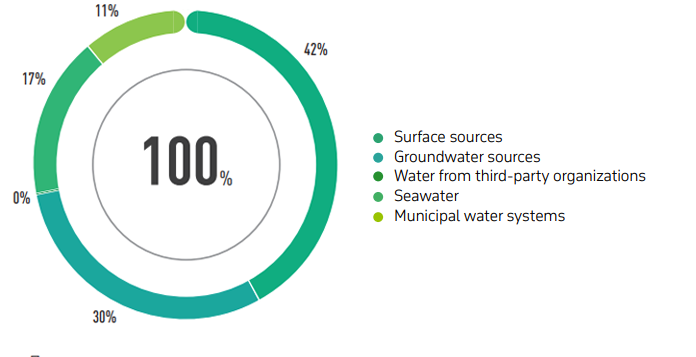

In 2024, KMG Group’s total water withdrawal amounted to 83.1 million m³. The main sources were surface water, groundwater, and seawater.

It is important to note that this total includes 24.08 million m³ withdrawn by a subsidiary providing technical freshwater supply services to consumers in the Atyrau and Mangystau regions – this volume is not used by KMG for its own domestic or production purposes. Excluding this volume, KMG Group’s own operational water use in 2024 amounted to 58.99 million m³.

TOTAL WATER WITHDRAWAL, THOUSAND M³

According to the World Resources Institute (WRI)6, Kazakhstan is located in a region of critical water scarcity, and a high level of water stress is projected over the next 15–20 years. KMG conducts a water use assessment in six of its subsidiaries located in regions facing elevated water scarcity, based on the WRI Aqueduct water stress indicator, including the Caspian Sea basin and the Syrdarya and Ural river basins. In 2024, the total water withdrawal in these regions amounted to 27.3 million m³.

6According to WRI Aqueduct: high category – total water stress 80-40 %, extremely high category – > 80 %.

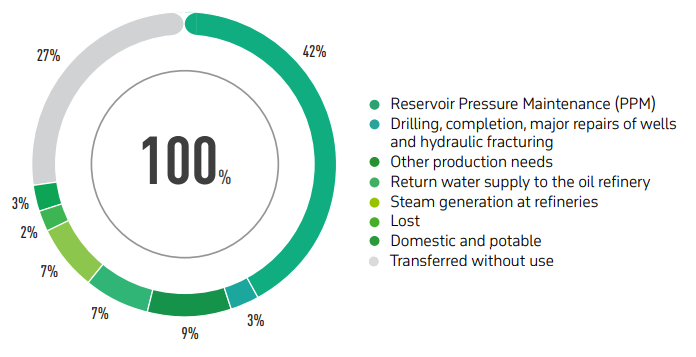

WATER USAGE STRUCTURE BY TYPE OF OPERATIONS

To minimize water shortages in these regions, KMG is implementing measures to reduce freshwater consumption, increase water recycling, and strengthen water use monitoring. At the same time, it is important to note that water availability is a critical factor for the Company’s operational activities.

WATER INTAKE STRUCTURE BY SOURCES FOR 2024, MILLION M<sup>3</sup>

WASTEWATER DISCHARGE AND REUSE

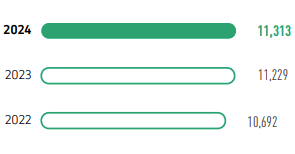

In 2024, the total volume of discharged wastewater amounted to 11.3 million m³. Treated wastewater is routed to specialized recipients, such as holding ponds, evaporation fields, and filtration fields. There is no direct discharge into surface water bodies or onto natural terrain.

Enterprises without their own storage facilities transfer wastewater to specialized companies for treatment. In 2024, the volume of such transferred wastewater amounted to 0.8 million m³ (all of which had a salinity level above 1,000 mg/l).

TOTAL VOLUME OF WATER DISCHARGES, THOUSAND M<sup>3</sup>

The wastewater discharge from KMG enterprises in water-stressed regions amounted to 2.98 million m³, of which 2.95 million m³ were directed to on-site wastewater recipients, and 0.03 million m³ were transferred to specialized treatment companies.

KMG considers wastewater not only as waste, but also as a potential resource for further use. The treatment facilities of the Company’s enterprises are equipped with technologies for removing petroleum products and suspended solids. For example, at refineries, wastewater undergoes mechanical and physicochemical treatment in grit chambers, oil traps, radial settling tanks, and flotation units, followed by biological treatment.

One of KMG’s key goals is to increase the reuse of treated wastewater. Water is reused in technological processes, irrigation of green areas, dust suppression at construction sites and roads, vehicle washing, and fire protection system replenishment. In 2024, a total of 8.5 million m³ of treated wastewater was reused.

A significant portion of treated wastewater is reused at refineries – 4.1 million m³ in 2024, which represents about a quarter of the total water withdrawal by KMG refineries.

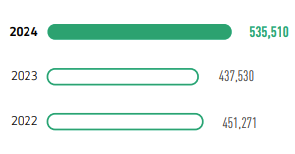

In recirculating water systems at KMG’s refineries, a total of 535.5 million m³ of water circulated in 2024.

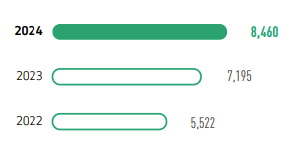

VOLUME OF WATER REUSED (AFTER TREATMENT), THOUSAND M<sup>3</sup>

VOLUME OF CIRCULATING WATER, THOUSAND M<sup>3</sup>

Produced Water Management in Oil Production

Oil extraction generates significant volumes of produced water. This water is brought to the surface along with the oil in the form of a water-oil emulsion, which is then separated by gravity. The treated water is injected back into the reservoir to maintain reservoir pressure.

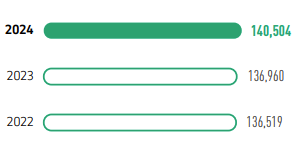

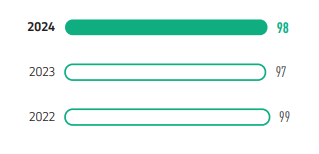

In 2024, the total volume of produced water amounted to 140.5 million m³, of which 98 % was reinjected. This demonstrates a high level of produced water utilization and minimization of impact on surface and groundwater resources.

VOLUME OF PRODUCED ASSOCIATED WATER, THOUSAND M<sup>3</sup>

SHARE OF ASSOCIATED WATER INJECTED BACK INTO RESERVOIR, %

Environmental Monitoring and Protection of Water Bodies

The production activities of KMG have the greatest impact on water bodies in the western region of Kazakhstan, including the Ural and Kigach rivers, as well as the unique Kokzhide sand ecosystem. These areas are of special environmental, economic, and cultural value.

To prevent negative impacts on these sensitive ecosystems, KMG implements comprehensive environmental monitoring, including continuous observation of the environmental condition and control of water quality. The Company’s activities in this area comply with national environmental legislation requirements and international sustainable water use standards.