ENVIRONMENTAL RESPONSIBILITY AND SAFETY IN THE WORKPLACE

01

OUR APPROACH

Ensuring industrial safety and environmental responsibility is the important task for us. The Company’s goodwill, reputation and financial well-being depend on successful solution of this task. Today we focus on transparency of environmental reporting, and thanks to this, for the second year in a row, KMG holds the highest place in the Rating of openness of oil and gas companies of Kazakhstan in the field of environmental responsibility*.

* Environmental responsibility rating for oil and gas companies https://www.zs-rating.ru/

Gas utilization growth

- In 2018, the highest level of APG utilization in the history of the KMG Group of Companies was reached – 93 %. The gas flaring rate is 6 tons per 1,000 tons of produced hydrocarbons, which is almost 50% lower than the IOGP global average. We continue to implement the World Bank Initiative “Complete Cessation of Regular APG Flaring by 2030” and intend to stop the practice of regular APG flaring no later than 2030.

OUR

Environmental indicators disclosure

- In 2018, we announced our participation in the Carbon Disclosure Project (CDP) initiative – an international community of investors for disclosure of information about direct and indirect greenhouse gas emissions and the risks associated with climate change, and began estimation of the carbon footprint of commercial products from the wellhead to end-use.

Environment: Businesses should maintain a cautious approach in dealing with environmental problems.

Environment: Businesses should take initiatives to promote greater environmental responsibility.

Environment: Businesses should encourage the development and diffusion of environmentally sound technologies.

HSE Management System

In September 2018, the Guidelines for Health, Safety and Environment Management Systems were approved. This document has changed the approach to managing HSE issues in the Company. The guide was developed based on the best international practices – recommendations of the Association of Oil and Gas Producers (IOGP) and applies to the KMG Group of companies. This system is based on four fundamental principles: Leadership, goal

achievement, risk management and continuous improvement.

Also, in KMG, since 2006, the management system in the area of quality, environmental protection, health protection and occupational safety is maintained in accordance with the requirements of ISO 9001, ISO 14001 and OHSAS 18001. Subsidiaries and dependent organizations with a significant level of energy consumption are certified to ISO 50001.

02

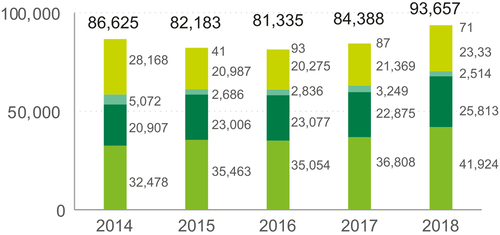

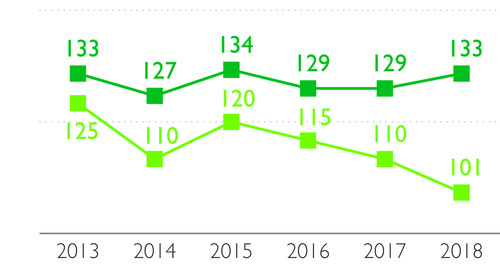

WORKPLACE SAFETY

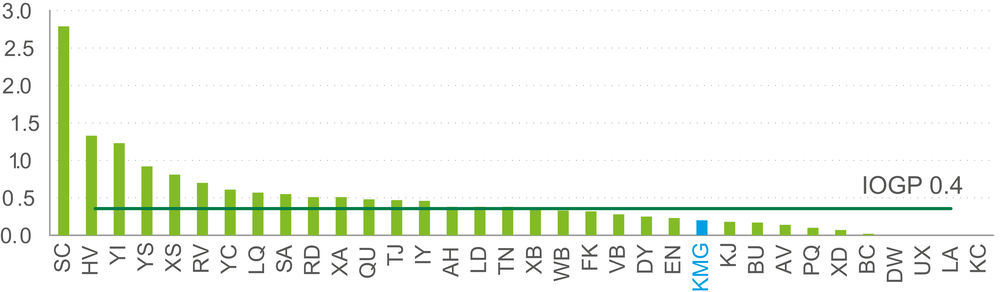

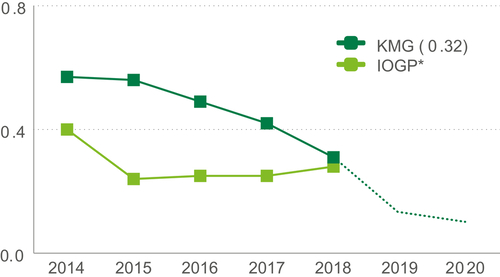

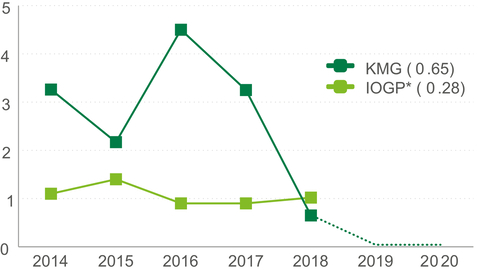

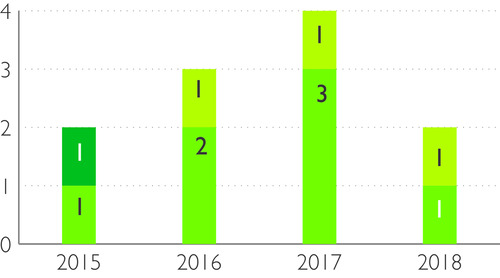

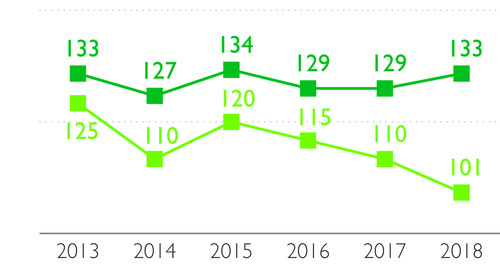

Over the past 4 years, great work has been done in KMG in occupational safety, industrial safety and environment (hereinafter referred to as HSE), while 2018 was the best in terms of safety and health indicators. We have achieved our goal – to enter the top 20 global industry companies in terms of safety by 2020 in terms of the fatal accident rate, and by 2020 the Company expects to enter the top-most injury rate.

The number of injured in accidents, including fatal accidents, decreased to a historic low – 35 % (50 injured in 2018) compared with 2017 (77 injured, respectively). As part of the membership in the International Association of Oil and Gas Producers (IOGP), we submit annual OSH reports and conduct benchmarking with global oil and gas companies.

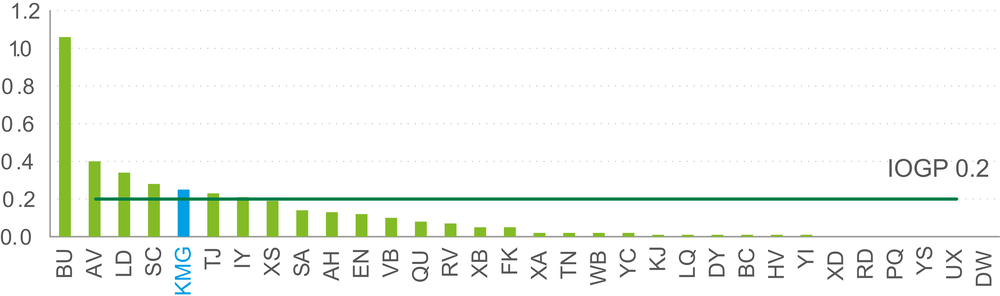

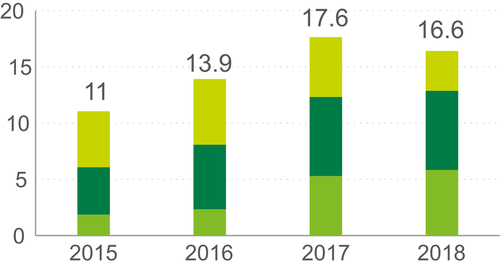

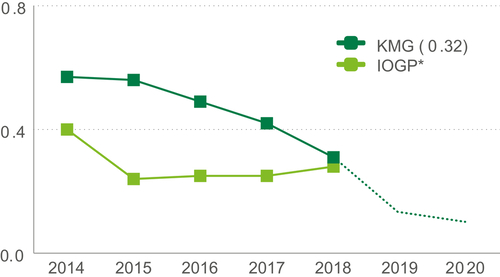

lost Time Incident Rate (LTIR per 1 million people-hours)

Fatality Accident Rate (FAR per 100 million people-hours)

* IOGP – International Association of Oil & Gas Producers (https://www.iogp.org/)

03

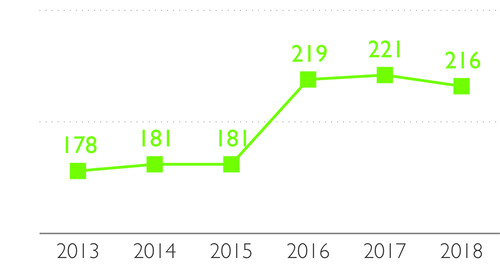

HEALTH CARE AND WORKPLACE HYGIENE

УManagement of issues in the area of health protection and work hygiene in KMG and SDEs is carried out in accordance with the requirements of Kazakhstani legislation: the Labor Code, the Health Code, the Sanitary Regulations and Instructions of the Republic of Kazakhstan, International Health protection and Work Hygiene Requirements. In addition, the Company enters into collective agreements with employees, in which special attention is paid to the protection of health and safety at the workplace. All employees of the Company are covered by an annual medical examination, in addition, employees of subsidiaries and affiliates undergo a daily pre-shift and post-shift medical examination.

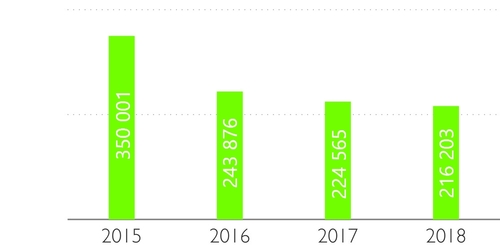

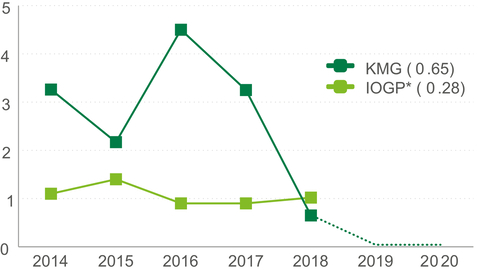

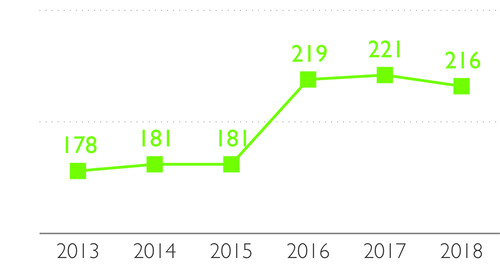

Number of days of incapacity for work due to diseases of employees of SDEs was 216,203 days in 2018, which is on 8,362 days less than in 2017, or 3.7 %. Number of mortality cases, not related to injuries among SDE employees decreased by 5 cases compared to 2017, or by 19.2 %.

KMG Group of companies takes a set of measures to prevent and monitor cases of detection of occupational diseases at production facilities on a regular basis. The final decision on identification of occupational disease is made according to the results of a number of examinations carried out by the relevant organization: Institute of Public Health and Professional Health of “MUK” NC JSC.

According to the results of medical examinations there were no cases of occupational diseases (acute or chronic) in the KMG Group of companies during the reporting period.

Within the framework of the implementation of the Roadmap on improvement of labor and the environment protection in the KazMunayGas Group – 2020, approved by the decision of the Board on 27.09.2016, corporate health programs are introduced by the KMG, first of all, related to reduction of workers diseases and mortality, not related to injuries.

In 2018, a corporate campaign to improve healthcare of KMG “Prevention of heart attacks and strokes” was developed and implemented, aimed at preventing and reducing mortality among workers associated with cardiovascular diseases. The implementation of the “10 steps to recovery” initiative and the internal regulatory document “Regulations on the organization of emergency medical care in the KMG Group”. The main tasks of these regulations are to establish requirements to provide workers with emergency medical care, to equip first-aid posts and to maintain an emergency medical response plan.

Number of days of incapacity

for work due to diseases

Number of mortality cases

not related to injuries

04

INDUSTRIAL SAFETY

In order to prevent accidents and incidents at all hazardous production facilities and to reduce the accident rate in 2018, the Company carried out the following activities:

• Systematic control of timely conduction of the survey, repair and replacement of technical devices;

• Strict adherence to technological discipline;

• Implementation of industrial control in the area of industrial safety;

• Full compliance with the industrial safety requirements established by laws and regulations.

In 2018, two accident occurred at the Company’s production facilities – a gas,

oil and water inflow in the oil and gas field, and depressurization of the process pipeline followed by ignition at the oil refinery. The main causes of accidents were a violation of industrial safety rules and unsatisfactory technical condition of the equipment due to its physical deterioration. The amount of losses amounted to 4.860 million tenge, no injuries.

In the occurred accidents, state technical investigation was carried out establishing causes and circumstances, and root causes were identified, corrective measures were developed at the Company’s corporate level with subsequent dissemination of “Lessons learned from Incidents” to all subsidiaries and affiliates.

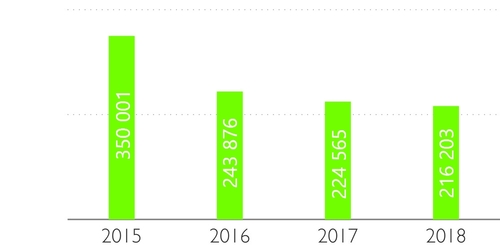

Accident rate (technological hazards) at the production facilities

Upstream

Midstream

Downstream

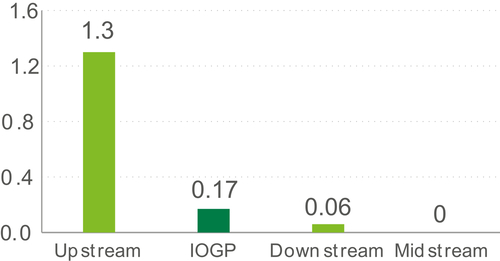

Tier 1 PSER industrial safety incident rate

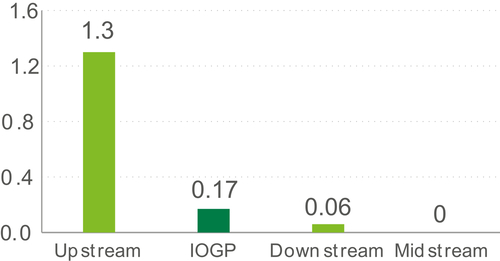

In the reporting year, benchmarking was conducted in the context of the Company’s business areas in terms of the Tier 1 Process Safety Event Rate (Tier 1 PSER) industrial safety incident rate with international oil companies that are members of the IOGP association.

This indicator for the IOGP group of companies is 0.17, which is significantly lower than the Company’s E&P subsidiaries and

affiliates, which was 1.3, and higher than the Company’s similar indicators for Processing and Marketing subsidiaries and affiliates (0.06) and Transportation subsidiaries and affiliates (0). In the Upstream business area, the majority of industrial safety incidents were caused by wear on pipelines and equipment breakdowns caused by corrosion.

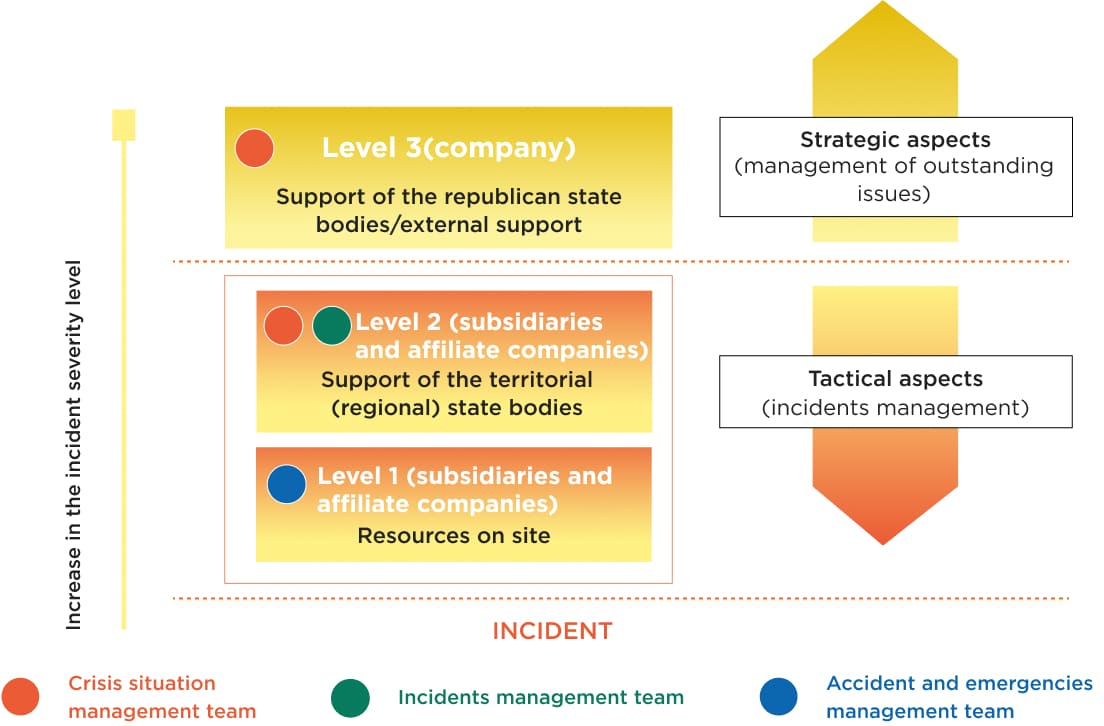

Emergency preparedness (crisis) situations

In the reporting year, the corporate center of the Company developed a draft Regulation on crisis management to ensure prompt response, prevent the escalation of possible crisis situations, reduce the severity of consequences and possible damage as a result of their occurrence.

The regulation assumes a three-level approach to managing incidents that can have a significant impact on the reputation of the Company and its subsidiaries and affiliates, its financial

well-being or long-term viability. Crisis situations are considered both of an industrial nature (accidents, fires, explosions, etc.) and not related to production (large-scale fraud, social unrest, acts of terrorism, etc.).

In all cases, the involvement of the Company’s senior management for making strategic decisions aimed at reducing the impact and minimizing the effects of crisis situations is envisaged.

Fire Safety

In 2018, the companies of the Group introduced fire safety rating sheets, which are aimed at checking the readiness of non-state fire services to prevent and extinguish fires.

Inspection and evaluation of preparedness for prevention and extinction of fires is carried out in order to determine the readiness of non-state fire services (NSFS), as well as the effectiveness of the fulfillment of contractual obligations in the field of prevention and extinction of fires at the Company’s facilities.

Scheduled inspections for evaluating the readiness of NSFS are carried out by employees of the HSE service, specialists in the field of fire safety of subsidiaries and associates of the company in accordance with plans approved by the heads.

According to the comprehensive analysis of the evaluation data, a number of subsidiaries and affiliates where it is necessary to take urgent corrective actions, such as: ensuring staffing of NSFS staff, building a fire station, the presence and staffing of fire engines in accordance with the regulations, etc., were identified.

Inspections are carried out on in the following areas:

1) availability of NSFS’s permits for implementation of activities in the field of fire safety regarding prevention and extinction of fires;

2) NSFS unit’s staffing with man-power, fire-technical equipment, RPD;

3) presence of a fire station building or specially designed boxes;

4) organization of man-power training;

5) organization of guard service;

6) organization of gas-smoke protection services;

7) organization of operation and maintenance of fire trucks;

8) organization of operation and testing of firetechnical equipment;

9) organization of fire prevention activities;

10) readiness for actions to localize and suppress the fire (based on the results of the test fire-tactical training).

Land Oil Spill Prevention

In 2018, the Company, as before, paid great attention to ensuring the integrity of pipelines as one of the important areas in the field of industrial and environmental safety.

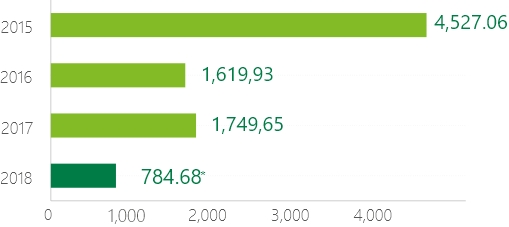

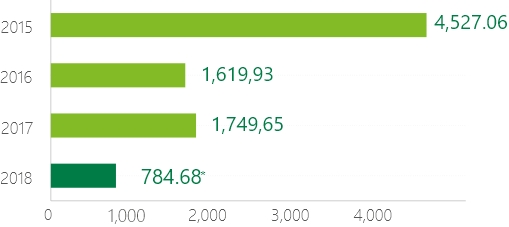

The volume of oil spills in 2018 decreased by 55 % compared with the level of the previous year and amounted to 784.68* tons. Last year’s figure was 1,749.65 tons.

These results are a consequence of implementation of programs to improve reliability of field pipelines in the Company’s E&P subsidiaries and affiliates aimed at replacing worn-out pipelines and protecting pipelines from corrosion by inhibiting.

* Indicator reflects data on oil spills in the “Upstream” business area.

The main cause of oil spills in the Company is impulses of field pipelines under the influence of corrosion processes. Therefore, in 2018 the Company continued to reduce the number of failures and gusts of field pipelines through the timely and highquality implementation of measures for diagnosis, reconstruction, replacement, inhibition and cleaning of pipelines aimed at improving their integrity and reliability.

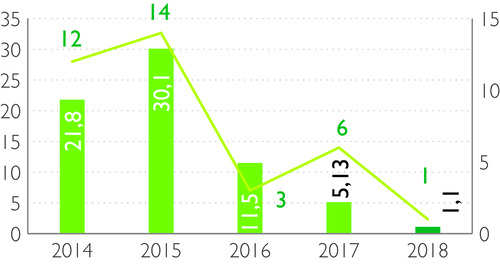

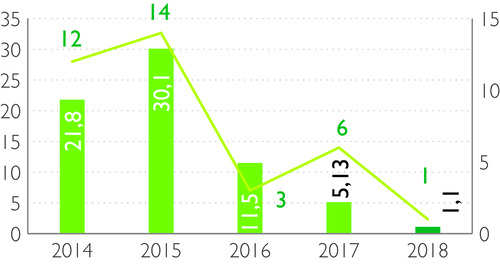

In close cooperation with law enforcement agencies, starting in 2012, “KazTransOil” JSC turned the tide of criminal illegal tie-ins into the company’s pipelines

Already in 2013, it was possible to reduce the number of unauthorized tie-ins from a few

dozen or even hundreds per year to 17 facts; at the end of 2014, 12 unauthorized tie-ins were revealed; in 2015, 14 frames were completed; in 2016 – 3 unauthorized connections, in 2017, 6 illegal tie-ins were revealed, in 2018 – 1 tie-in.

These indicators are achieved largely due to the implementation of the following activities:

• strengthening control over the monitoring of the work of mobile groups on GPS systems and the timely implementation of mobile groups of detours and inspections of pipelines;

• strengthening control over the monitoring of the work of mobile groups on GPS systems and the timely implementation of mobile groups of detours and inspections of pipelines;

Oil Spill Volume, tons

Unauthorized Tie-Ins

Total damage, mln KZT

Number of unauthorized tie-ins, pcs

05

ENVIRONMENTAL INDEX

In accordance with the precautionary principle (Principle 15 of the Rio Declaration on the Protection of the Environment and Development of the United Nations), as well as the requirements of the KMG environmental management system and the provisions of the legislation of the Republic of Kazakhstan at the planning stage of each project, an environmental impact assessment (EIA) is carried out to determine the environmental and other effects of management and business decisions, develop recommendations for improving the environment, preventing destruction, degradation, damage and depletion of natural ecological systems and natural resources. In addition, at the design stage of each project, public hearings are held with the participation of representatives of interested parties: administrative, state and regulatory bodies, research organizations, public associations, the local population, the media.

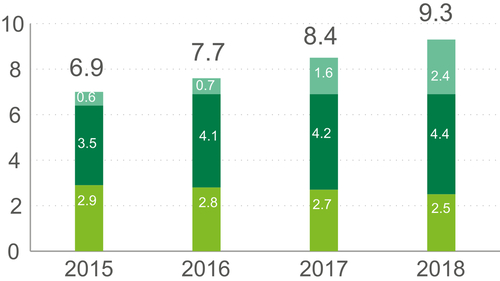

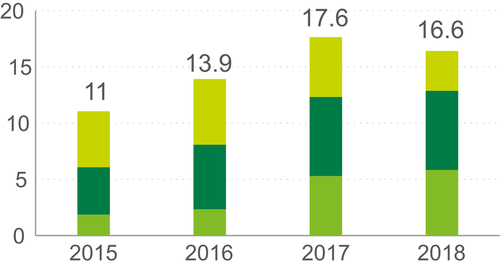

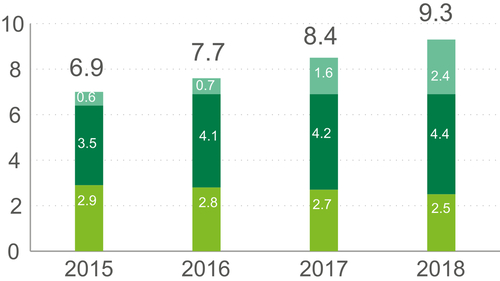

Dynamics of environmental payments and costs, bln KZT

Waste recycling

Other environmental costs

НRegulatory emission payments

We provide access of all interested parties to the draft EIA, reception and registration of comments and suggestions. All KMG Group EIA projects are subject to state environmental impact assessment and are available to the public concerned on the official website of the Company, on the websites of local authorities throughout the project life cycle. In the period 2017–2018, 95 meetings were held with the local community and public organizations, including 45 meetings in 2017 and 50 meetings in 2018. According to the results of public hearings, appropriate measures are taken, taking into account the recommendations and opinions of stakeholders.

In order to effectively manage environmental risks, the Company is constantly improving approaches to environmental management and allocates the necessary resources to protect the evironment, in pariculary for environmental costs, which include the payment of taxes for regulatory emissions, the cost of environmental protection measures, insurance, compensation measures in the field of environmental protection, investments in environmental impact prevention, etc. The Company has increased the budget for processing historical waste and restoring polluted land. Since 2015, investments in waste recycling have increased 3 times and account for more than a third of all environmental protection costs. At the same time, there is a decrease in emission payments associated with a reduction in atmospheric emissions by increasing the use of associated petroleum gas.

Use of Energy Resources and Energy Performance

The company’s activities in the field of energy conservation and energy efficiency are based on the methodology of the international standard ISO 50001 “Energy Management Systems”, which is the best generally recognized international practice for system management in this activity.

Since 2017, KMG has a Roadmap on energy saving and energy efficiency of subsidiaries and affiliates, including jointly controlled organizations and joint ventures of KMG for 2017–2020.

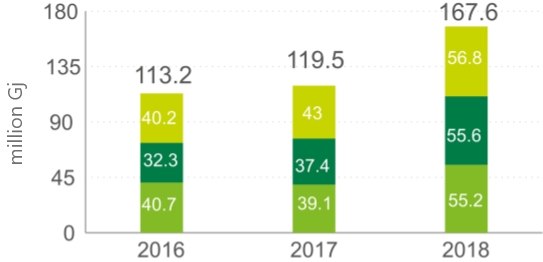

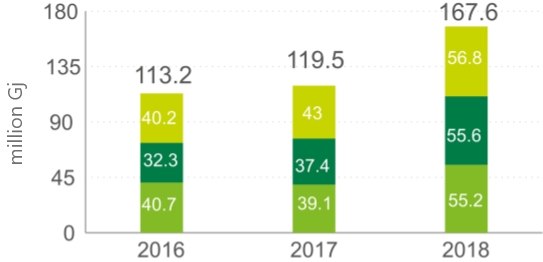

Energy Consumption

The increase in energy consumption 2017 is primarily due to the modernization of refineries and the introduction of new technological units and to increase the depth of oil refining, as well as the increase in production watering at mature fields.

In 2018, the volume of own generated energy in the KMG Group of companies amounted to 683.4 million kW (2.5 million Gj) of electrical

energy and 3,812.5 thousand Gcal (16.0 Gj) of thermal energy.

Energy contribution by area of activity

Upstream

Midstream

Downstream

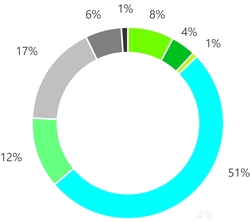

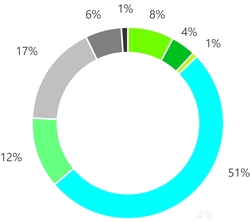

Energy consumption (by type), %

Electricity

Thermal energy

Oil

Natural gas

APG

Boiler and furnace fuels

Burner fuel

Diesel fuel

Reducing Energy Consumption*

In 2018, 59 energy saving and energy efficiency measures were carried out, main main of which are technological equipment upgrade, implementation of devices for reactive power compensation, introduction of energy-saving technologies, thermal energy production and consumption optimization. Saving of fuel and energy resources amounted to 436.8 thousand Gj, in-kind 16.8 MMkW (60.6 thousand Gj) of electricity, 8.8 thousand Gcal (37.1 thousand Gj) of thermal energy, 9.6 million m3 (324.3 thousand Gj) of natural gas and 458 thousand liters (14.8 thousand Gj) of fuel and lubricants.

Due to the fact that the main measures for energy saving and energy efficiency, namely the introduction of technological equipment was realized in the end of 2018, the economic effect in kind of energy resources will be visible only in 2019. The financial expenses for the implementation of these measures amounted to KZT 1.8 billion. Saving financial expenses for the purchase of fuel and energy resources amounted to KZT 395,2 million. The planned payback period is 4.6 years.

* In the Annual report for 2018, operational data on reducing energy consumption were indicated.

Energy Intensity

In 2018, the specific energy consumption in the direction of hydrocarbon production averaged over the Group of companies was 2.38 Gj per ton of produced hydrocarbons, which remains 59 % higher compared to the international association of oil and gas producers IOGP, which in 2017 was 1,5 Gj per ton of produced hydrocarbons. In oil production, the specific consumption of energy resources is primarily due to the increase in water cut in production at mature fields.

In 2018 the specific energy consumption in the direction of oil refining averaged at the refinery was 3,5 Gj per ton. This is 15 % higher than the level of European plants and is primarily associated with the harsher climatic conditions in the region of the petrochemical enterprise. In the reporting year, the increase in specific energy consumption is associated with the modernization of the plant, the construction of new ones and the reconstruction of existing process units to increase the depth of oil refining.

In 2019, the implementation of measures for energy saving and energy efficiency will continue, the results of which will save at least 0.8 million Gj of energy.

As part of the modernization in 2019–2021, the refinery plans to introduce an automated system for technical accounting of electricity, which is implemented on the basis of microprocessorbased computing facilities and control complexes, which is a computerized system with centralized control and a distributed measurement function.

The implementation of this project will lead to a reduction in energy costs due to the organization of reliable technical accounting, rational distribution and consumption of electricity.

Water Management

The key event in terms of water resources protection in 2018 was the adoption by the Company of a corporate standard for water resources management, which will be gradually introduced in the Group of companies during 2019.

The standard postulates the main principles of KMG regarding the use of water resources – 8 “Water” principles, systematizes the approach to water management in KMG subsidiaries and affiliates, and also helps to increase the commitment of managers and employees to the issue of freshwater conservation.

Also in 2018, the modernization of the treatment facilities of “PKOP” LLP (Shymkent Refinery) was completed: the capacity of the plant’s treatment facilities was increased, and the quality of wastewater treatment was improved. Additional wastewater treatment at the reverse osmosis unit saves fresh water of up to 1.5 million m3 per year. In addition, a system for returning treated wastewater to the fire protection system has been introduced at the treatment facilities of PKOP. These measures will help to save up to 30 % of fresh water previously collected from urban water supply systems.

Water Footprint

In 2018, KMG Group of companies discharged 10.9 million m3 of wastewater (9 million m3 in 2017). The main receiver (and end point) of KMG enterprises is various specialized receivers: storage ponds, evaporation fields and filtration fields. These facilities are technical facilities designed for natural wastewater treatment and prevention of environmental pollution.

Enterprises that do not have their own drives transfer wastewater for cleaning and disposal to specialized companies. Quality standards for discharged water, established by environmental legislation, are achieved through the use of mechanical and biological methods of wastewater treatment.

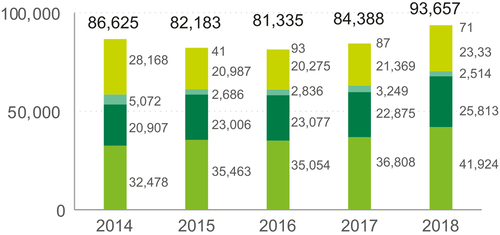

Water withdrawal sources breakdown of KMG Group, thousands of m3

Surface sources

Underground sources

Municipal systems

Sea

Sewage of other enterprises

A significant amount of treated wastewater is used for the second time at refineries, where in 2018 4.1 million m3 of treated wastewater was reused, mainly this water is used to feed recycled water supply units. In total, 360 million m3 of water was used (circulated) in the KMG refinery’s water recycling systems.

The percentage of water reuse at KMG’s plants is 26 % (of the volume of water withdrawal in the direction of Recycling). Purified wastewater in the Mining and Transportation sectors is reused mainly for cleaning vehicles, dust suppression and fueling systems.

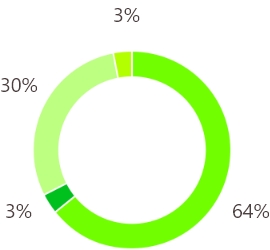

Use of water resources by type of operations in 2018, %

Production needs

Drinking needs

Transmitted without use

Technical losses

In the process of oil production large volumes of so-called, associated-formation waters – an oil-water emulsion is extracted to the surface, which is subsequently separated into water and oil by the gravity method. The water thus separated is sent for injection into the reservoir. A total of 124.4 million m3 of produced reservoir water in 2018, 99 % was pumped back to maintain reservoir pressure, and only 1 % into absorbing wells. Significant volumes of produced-surface water extracted to the surface, as well as a gradual increase in its volumes, indicate a depletion of oil fields (an increase in water-cut).

In addition, in order to maintain reservoir pressure, 47.8 million m3 of water from other sources (23.3 – sea water,

7.2 – Volga and 17.3 – water from underground sources).

The most significant impact of the Company’s activities is on the water bodies of the western region of Kazakhstan (the Ural and Kigach rivers, the Kokzhide sands, the Pyatimar reservoir), which are of particular ecological, economic, historical, cultural and recreational value. To prevent negative impacts on sensitive ecosystems, regular monitoring is conducted.

Total volume of produced water, thousand m3

| 2015 |

2016 |

2017 |

2018 |

| 121,933 |

123,172 |

124,416 |

124,372 |

Natural areas of our operations under protection and affected species of flora and fauna

Location and scale of production activities in relation to key biodiversity areas

Offshore oil spill prevention

The absolute priority for the Company is to ensure constant preparedness for the elimination of all possible emergency oil spills before drilling operations at sea begin. Therefore, the Group has a system for ensuring prompt and effective response to emergency situations, including oil spills and the implementation of appropriate operations to eliminate their consequences. To increase the level of preparedness for oil spill response (hereinafter – OSR), practical and theoretical exercises, trainings and exercises of various levels are regularly held to improve the practical skills of personnel.

In the event of a possible spill, contracts are also concluded with specialized companies for the elimination of oil spills of the first and second levels. In the event of a spill of the third level, an agreement is concluded with the international association Oil Spill Response Limited, specializing in the elimination of accidents at offshore oil and gas fields.

In 2018, before the start of the construction of the appraisal well in the Zhambyl

section, to ensure readiness for the OSR, an agreement was concluded with a consortium represented by “KMG Systems & Services” LLP, “Kazmortransflot” LLP and Republican State Enterprise on the right of economic management “Professional Militarized Emergency Rescue Service“. For the entire period of construction of the appraisal well, the vessels for the OSR were in the 500 meter zone from the rig.

Also, the Operator at the Zhambyl site conducted a series of command and staff exercises on first and second level OSR with the participation of representatives of state bodies in the field of industrial safety and ecology.

A subsidiary of “KMG Systems & Services” LLP owns the North Caspian Environmental Oil Spill Response Base in Atyrau Oblast, the only specialized facility in Kazakhstan intended for OSR.

During the reporting period, no oil spills were recorded in the Caspian Sea.

Climate Change and Air Quality

In 2018, the Emission Management Policy was developed in the KMG group of companies, where the main principles of managing activities to reduce the harmful effects on the atmosphere are defined:

We give primary attention to measures to minimize negative impact of our activities on the environment, observing the requirements of environmental legislation, rationally using natural resources and constantly improving environmental protection activities. Our priorities are the careful and rational

use of natural resources, the minimization of environmental risks.

Targeted programs are aimed at reducing the combustion of crude gas in flares, developing green energy based on renewable energy sources and improving overall energy efficiency.

The Emission Management Policy in the KMG group of companies:

1

carrying out activities in strict accordance with legislative requirements and other obligations of the Company;

2

compliance with the established emission standards and emission limits, quotas for greenhouse gas emissions;

3

a clear distribution of roles and responsibilities, increased competence, training and awareness;

4

conducting regular accounting, inventory and monitoring of emissions;

5

the termination of the regular combustion of crude gas in the extraction of hydrocarbons;

6

taking measures to reduce greenhouse gas emissions and reduce the carbon footprint;

7

carbon asset management;

8

continuous improvement of emission management activities.

Greenhouse Gas Emissions

For the first time, KMG has developed a Carbon Disclosure Information Project under the Carbon Disclosure Project (CDP), which disclose data on direct and indirect greenhouse gas (GHG) emissions for 2018 for all KMG assets, including international (Romania, Georgia).

emissions

Data on GHG emissions for 2018 will be verified and will be available at the CDP site on following link: https://www.cdp.net*

* The Questionnaire will be posted on the CDP platform in mid-2019. To view the Questionnaire, follow the link in the “Search” section and enter the company name in English: “KazMunayGas National Company JCS”. Methodology for calculating greenhouse gas emissions, as well as the disclosures 305-2, 305-3, 305-4, 305-5, were described and posted on the CDP site.

Methane Leak Direct Detection Project

Since 2017, KMG has been a member of the Global Methane Initiative (GMI) project network. In 2018, pilot projects were carried out to detect and quantify methane leaks at the Company’s production facilities in Mangistau Oblast.

History Case:

Due to the launch of the integrated gas processing unit at the Prorvinskaya group of fields, the volume of direct GHG emissions from the flare in this organization was reduced by 80 % and amounted to 41.5 thousand tons (211.6 in 2017).

One of the basic principles of the Emission Management Policy is Subparagraph of Principle 6: The company takes measures to prevent methane leaks at production facilities by conducting campaigns to detect and quantify methane leaks, install floating cisterns in new tank farms, introduce light oil fractionation plants, the use of mobile compressor stations in the repair of gas pipelines.

KMG took part and represented the Republic of Kazakhstan at the meeting of the GMI Oil and Gas Subcommittee during the Global Methane Forum held in April 2018. in Toronto (Canada). KMG participates in the international project of the United Nations Economic Commission for Europe “Project on MRV (monitoring, reporting and verification) and reducing methane emissions in the oil-producing and extractive industries”.

CO2 emissions from biomass burning or decomposition are not included.

In its activities, the Company does not release ozone-depleting substances that affect climate change. Periodic control and monitoring are conducted.

In order to minimize the impact of gas storage, 3 underground gas storage facilities are used to store natural gas (UGS). The largest of them UGS “Bozoy” (with an active storage capacity of 4,000,000 thousand m3) is located in the Aktobe region (UMG “Aktobe”). There are also UGS “Poltoratskoe” (with an active storage capacity of 350,000 thousand m3), located in the Turkistan region (UMG “Shymkent”), as well as the UGS “Akyr-tobe” (with an active storage capacity of 300,000 thousand m3), in the Zhambyl region (UMG “Taraz”). Underground gas storages are intended to provide consumers with natural gas during the winter seasons, as well as during periods of reduced gas supply.

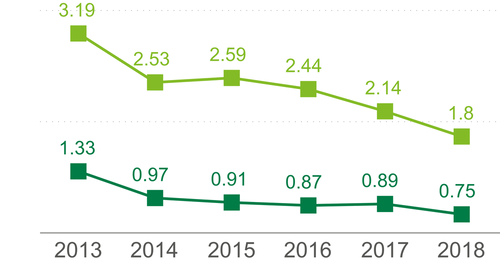

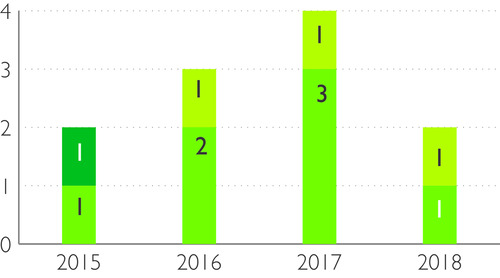

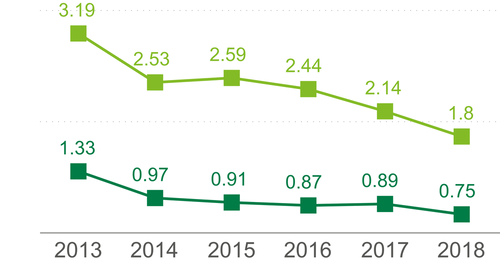

Emissions intensity СО2 in Upstream, ton/1,000 tons

KMG

IOGP

Emissions intensity in Downstream, ton/1,000 tons

KMG

Emissions intensity СH4 in Upstream, ton/1,000 tons

KMG

IOGP

Direct greenhouse gas emissions by business area

Upstream

Downstream

Midstream

Air quality

Gross emissions of pollutants into the atmosphere in the KMG Group of companies, thousand tons

|

2016 |

2017 |

2018 |

| Emissions of pollutants into the atmosphere, in total, including: |

241.1 |

256.3 |

269.3 |

| NOx emissions |

12.9 |

13.8 |

16.7 |

| SOx emissions |

16.9 |

14.8 |

13.6 |

| emissions of other pollutants |

211.3 |

227.7 |

239.1 |

We conduct industrial environmental monitoring and take measures on reduction of emissions of pollutants into the atmosphere, formed in the result of operations and production processes. As part of industrial environmental monitoring programs, emissions to the atmosphere are monitored at designated sampling sites and measurements are made to assess potential impacts. The main amount of pollutant emissions is generated as a result

of fuel gas combustion in boilers, process furnaces and compressors, gas turbine plants, compressor stations, gas flares, etc.

The actual gross amount of emissions of all pollutants for the Group in 2018 amounted to 269 thousand tons (in 2017, 256 thousand tons). There is a slight increase in emissions due to the introduction of new sources into operation.

Sulfur production facilities were commissioned in all plants. With implementation of this project, hydrogen sulfide gas will undergo regeneration, while simultaneously obtaining an important production product – marketable sulfur. This affects the reduction of pollutants in the exhaust gases of road transport and the improvement of air quality in populated areas. The sulfur content in gasoline K4 is 10 times less than in the fuel produced before the modernization of the plant.

As a result of carried out projects for the modernization of oil refineries, environmental indicators of fuel produced by plants were improved by producing oil products of European quality standards corresponding to K4 classes in accordance with the requirements of the Technical Regulations of the Customs Union.

Specific emissions of pollutants in the KMG Group of companies

|

2016 |

2017 |

2018 |

| Mining of hydrocarbons, t/1,000 TOE of extracted hydrocarbon raw materials

|

2.14 |

2.35 |

1.93 |

| Oil refining, t/1,000 tons of refined oil |

3.3 |

3.3 |

3.3 |

| Oil transportation, t/1,000 tons of oil transported |

0.5 |

0.5 |

0.5 |

| Gas transportation, t/1,000 TOE transported gas |

1.4 |

1.2 |

1.4 |

SOx emissions per thousand toe of raw hydrocarbon production in 2018

NOx emissions per thousand toe of raw hydrocarbon production in 2018

Average ratio of NOx emissions to total raw hydrocarbon production in oil equivalent by KMG Group of companies was 0.2 ton per thousand ton of raw hydrocarbon production in 2018, average IOGP indicator was 0.4. Compared to 2017, there is a 17 % drop in in NOx emissions.

Average ratio of SOx emissions to total raw hydrocarbon

production in oil equivalent for KMG Group of companies was 0,25 ton per thousand ton of raw hydrocarbon production, average IOGP was 20%. Compared to 2017, there is a reduction in SOx emissions.

The Company does not release persistent organic pollutants in its activity.

Beneficial use of crude gas

This section contains information on companies in the “Upstream” business area of the KMG Group.

One of goals in reducing greenhouse gas emissions is to increase the beneficial use and utilization

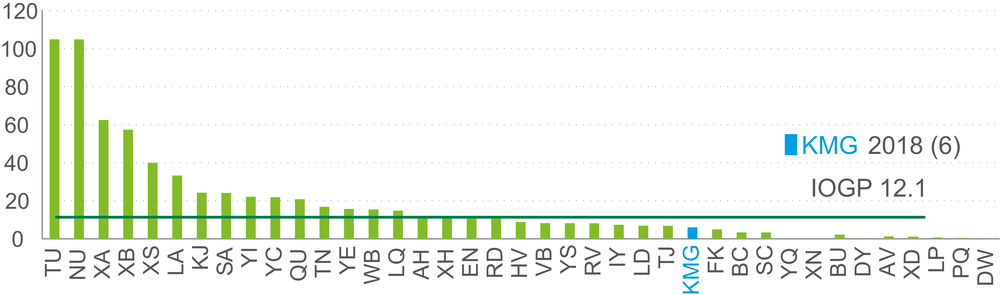

of associated petroleum gas, minimizing flaring. Associated petroleum gas utilization in 2018 is the highest in the entire history – 93 %, gas flaring is at 6 tons per 1,000 tons of produced hydrocarbons (11 in 2017), which is almost 50 % lower than the average IOGP.

This was achieved due to the commissioning of a comprehensive gas processing unit (GPU) at the Prorvinskaya group of fields and a reduction in gas production and combustion in the oil-producing assets of the Aktobe region.

The volume of natural and associated gas production by the main producing companies of the KMG Group in 2018 amounted to 2,873 million m3 (including associated petroleum gas (APG) – 2,049.5 million m3), the volume of crude gas burned was 148.9 million m3. At the end of 2018, a modern gas processing complex was put into operation in the Baiganinsky district of the Aktobe region at the Kozhasai field. The Head of the State opened its work online during a national teleconference dedicated to the Day of Industrialization.

Commissioning of the integrated gas processing unit at the Kozhasai field into full-scale operation will significantly reduce gas flaring from 173 million m3 to 50 million m3, which will have a positive effect on the reduction of pollutant emissions (by 70 %).

In 2015, KMG supported the World Bank’s initiative “Complete utilization of associated petroleum gas by 2030”. On November 20, 2018, working meetings were held with representatives of the World Bank Group to discuss the status of the implementation of the initiative in KMG and possible cooperation to reduce regular burning of crude gas. Reporting on the volume of combustion of crude gas under this Initiative is submitted on an annual basis.

The company does not recycle APG.

Benchmarking of APG flaring rate by industry

The volume of crude gas flaring

|

2016 |

2017 |

2018 |

| Total volume of crude gas flaring, million m3 |

322.8 |

315.8 |

148.9 |

| The beneficial use of APG, % |

86 |

85 |

93 |

| The intensity of burning of crude gas, t/1,000 produced by raw hydrocarbons |

12 |

11 |

6 |

Construction of infrastructure and modern facilities for the utilization of crude gas make it possible to fully develop mining assets and significantly reduce greenhouse gas emissions and pollutants into the atmosphere.

In 2018, the average ratio of gas burned to total hydrocarbon production in oil equivalent for the KMG Group of companies was 6 tons per thousand tons of hydrocarbon production, the average IOGP was 12.1.

Waste Management

Waste management in companies of the Group is one of the most important environmental aspects for KMG. Criticality lies primarily in the substantial amounts of hazardous waste formation inherent in the oil industry. For the quality control of this process, the Company develops a system for managing industrial waste, constantly improves the accounting for the generation and movement of waste, increases the potential for increasing waste reuse.

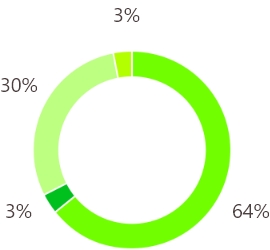

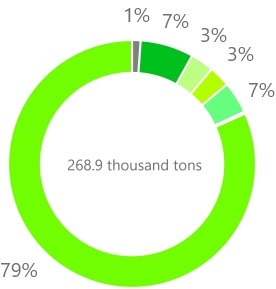

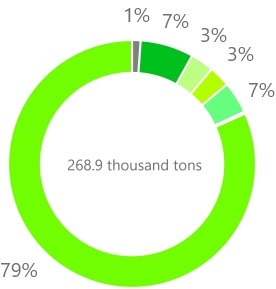

Hazardous waste for 2018 by type treatment, %

Reuse

Secondary processing

Recovery

Combustion (or use as fuel)

Placement at the disposal site

Storage at the enterpresise’s site (0.3%)

Transfer to a specialized organization

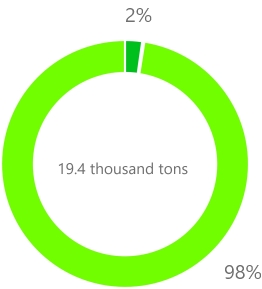

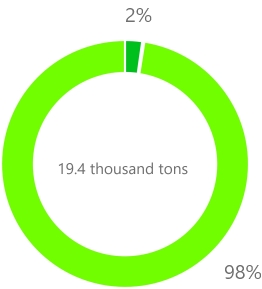

Volume of generated wastes in 2018 is 288.3 thousand ton (14 % less than in 2017), among them 268.9 thousand ton were classified as “hazardous”, and 19.4 thousand ton as “unhazardous”. Most part of hazardous waste 67 % are drill mud (drill cuttings and waste drilling mud). The reduction in total waste generation compared with 2017 was primarily due to the reduction in drilling waste generation.

Unhazardous waste for 2018 by type treatment, %

Reuse

Placement at the disposal site (0.12%)

Storage at the enterpresise’s site (0.12%)

Transfer to a specialized organization

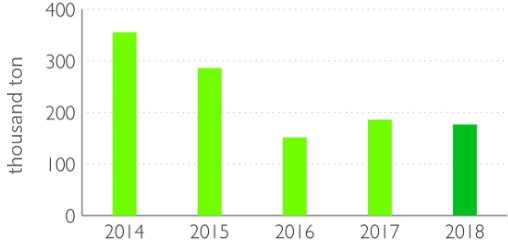

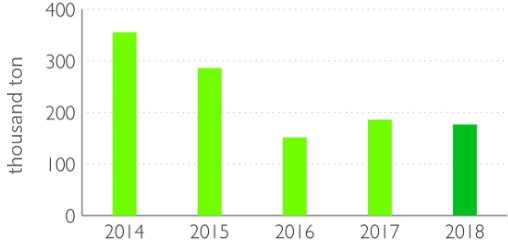

Drill mud generation

In 2018, Extracting companies of the KMG generated 176.4 thousand ton of drill mud (6 % less than in 2017), including: 38.4 thousand ton of waste drilling mud; 138 thousand ton of drilling cuttings. All drill mud of extracting companies of the KMG Group is transferred to specialized organizations for disposal. Methods of further waste disposal by these companies: inertisation, thermal method, chemical method, biological remediation and dumping at special disposal sites.

KMG waste drilling mud generation

Transportation of hazardous wastes

KMG does not import/export hazardous wastes outside/within Kazakhstan.

06

COMPLIANCE WITH THE REQUIREMENTS

We try to conduct our production activity within the framework of the legislation of the Republic of Kazakhstan and to take appropriate measures to prevent environmental damage.

The Company will continue its work on detection of inconsistencies with the environmental legislation of the Republic of Kazakhstan at production facilities, on identification of problem issues and risks management to take measures on prevention of any inconsistencies with the requirements of the legislation.

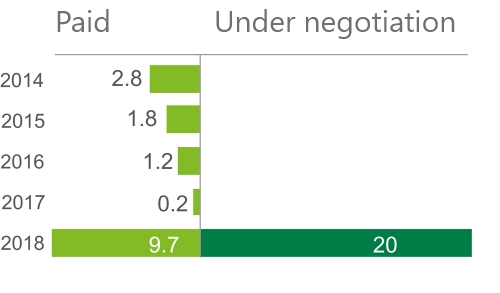

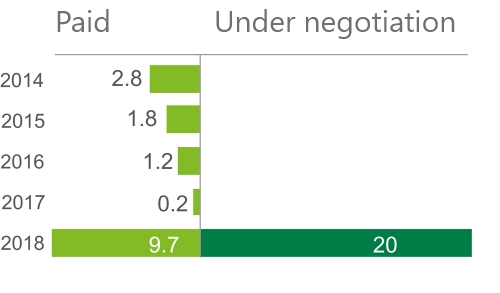

For 2018, the environmental protection Group of KMG companies was charged with administrative fines, damages and tax payments for excess emissions in the amount of KZT 85.6 billion, of which the Company recognized and actually paid KZT 9.7 billion, contested in court 55.9 billion tenge. The remaining claims are disputed by the Company in court as unlawful.

One of the extractive companies was imposed an administrative penalty for disposing of production waste at landfills without permits for emissions into the environment for periods amounting to KZT 55.9 billion. KMG was able to prove the illegality of the claim and in January 2019, by decision of the judicial division in civil cases, it was decided to cancel the administrative fines and tax payments and terminate the proceedings.

Environmental Fines 2014–2018, bln tenge

Another company for burning sour gas without a permit in the flare of the Complex Gas Treatment Facility imposed penalties of KZT 29.7 billion, including administrative fines, damages for environmental pollution and tax payments for excessive gas flaring. The reason for the excess of the acid gas combustion rate was the delayed launch of the LO-CAT desulfurization system at the CGTP. The desulfurization system began to work at the end of 2018, and the flaring of sour gas at the flare was immediately stopped. Of the amount claimed, in 2018 KZT 9.2 billion was actually paid. For the remaining amount, litigation is ongoing.

In 2018, non-financial sanctions were also applied to one of the Company’s oil refineries, namely, such requirements were set as: to adjust the design of permissible discharges, comply with established standards for the concentration of pollutants in wastewater, take the necessary measures to improve the efficiency of treatment facilities, develop plan for the modernization of treatment facilities. The Company carried out work on all of the above items.