Principle 7. Environment: Businesses should support a precautionary approach to environmental challenges

Principle 8. Environment: Businesses should undertake initiatives to promote greater environmental responsibility

Principle 9. 9 Environment: Businesses should encourage the development and diffusion of environmentally friendly technologies

OUR APPROACH TO MANAGEMENT

Occupational health, safety, and environmental (HSE) management objectives are directly linked to the Company’s Development Strategy. The KMG Development Strategy until 2028 (hereinafter – the Strategy) provides for strategic initiatives to improve the environmental responsibility. The Company’s priorities in the field of environmental protection include managing greenhouse gas emissions and reducing gas flaring, water management, waste management, land remediation, and energy efficiency.

In accordance with the priorities of the KMG Strategy, the HSE Policy has been divided into two separate H&S policy and environmental policy approved by the Board of Directors in 2020. The KMG Management and its subsidiaries and affiliates follow the principle of zero tolerance towards losses and damage related to contamination of the environment.

KMG is a participant of the World Bank’s Global Initiative to Reduce Gas Flaring by 2030 announced in 2015 to unite the efforts of states, petroleum companies, and public organisations in order to increase the beneficial use of associated petroleum gas. As part of implementation of the above initiative, the Company follows the Emission Management Policy at KMG aimed at full cessation of regular gas flaring and comprising eight key principles.

In 2020, the Corporate Standard for Environmental Impact Assessment was developed and approved by resolution of the Management Board. The standard is a part of the Health, Safety and Environment Management System Regulations of the KMG Group. The standard specifies the corporate principles of the environmental impact assessment of the planned activity, regulates the activities of the KMG Group and contractors of the KMG Group, including design organisations whose activities relate to development of technical documentation and documents for environmental impact assessment, arrangement and performance of recording of public opinion regarding the environmental impact assessment documents, and obtaining of emission permits.

The main strategic initiatives in the field of environmental protection and sustainable development are specified in the Roadmap for Improvement of the Occupational Health and Environment – 2020 and the Action Plan for implementation thereof.

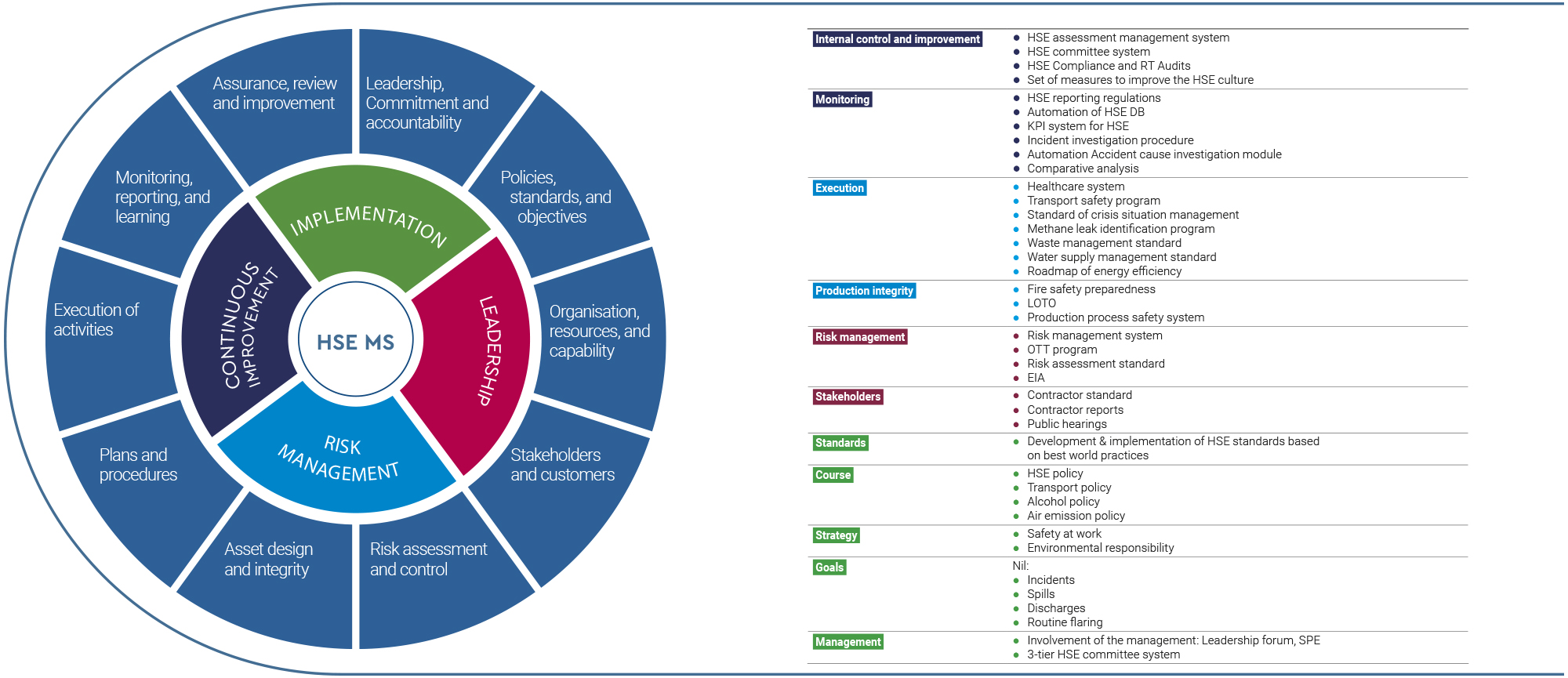

HSE management system

The company has a functioning health, safety, and environment management system (MS) developed in conformity with the requirements set forth by the laws of the Republic of Kazakhstan, industry-specific and international standards ISO 14000 and ISO 45001, as established by the best world practices, approaches, and recommendations of the International Association of Oil & Gas Producers (IOGP). The system includes 10 key elements based on the following fundamental principles: Leadership, Implementation, Risk Management, and Continuous Improvement.

STRUCTURE OF THE HSE MS AND IMPLEMENTATION OF THE BEST INDUSTRIAL PRACTICES

Taking into account best practices in health, safety and environment (HSE) management, a three-tier committee system has been introduced and implemented to increase the commitment and involvement of managers at all levels and employees in HSE management processes:

- Level one – Health, Safety, Environment and Sustainable Development Committee of the Board of Directors of KMG (HSESDC);

- Level two – HSE Committee at the KMG level;

- Level three – HSE committees of the subsidiaries and affiliates.

Starting from 2019, the Health, Safety, and Environmental Protection Committee has been functioning at the level of JSC “Samruk-Kazyna”. In 2020, KMG actively participated in the work of the Committee and the Committee Expert Group. As part of the Committee and the Expert Group work, the portfolio companies of JSC “Samruk-Kazyna” actively share their experience and develop uniform approaches to HSE, including those related to countering the pandemic. Many approaches of the KMG in the field of HSE and countering the pandemic have been adopted by other portfolio companies as examples of best practices.

Reports on occupational health, safety, and environmental protection are monthly reviewed during the sessions of the KMG Board of Directors and the detailed reports are reviewed by the HSESDC of the KMG Board of Directors. The HSESDC sessions in 2020 included detailed discussion of the following key issues in 5 meetings:

- improvement of the beneficial use of associated petroleum gas;

- environmental rating results;

- biodiversity preservation;

- water resources management;

- climate change.

HSE risks are monitored monthly, including environmental risks and risks related to climate change and water deficit. KMG regularly analyses environmental indicators, performs benchmarking of equivalent indicators of the leading international petroleum associations (IOGP, IPIECA, CDP), and audits production facilities. The company pays special attention to the environmental aspects and assessment of environmental risks. The Company develops draft environmental impact assessments for planned activities, holds public hearings, and implements environmental protection measures.

Improvement of the health, safety and environment (HSE) management system:

The following corporate documents were developed, updated, and approved in 2020:

- HSE Risk Communication and Awareness Plan of JSC NC "KazMunayGas” Group;

- Corporate standard of “Uniform System of Safety Management at JSC NC "KazMunayGas” Group”;

- Corporate standard of Production Process Safety Management at JSC NC "KazMunayGas” Group”;

- Corporate standard of Interaction with Contractors in the Field of Health, Safety and Environment at JSC NC "KazMunayGas” Group;

- Regulations on Application of Korgay Map for JSC NC "KazMunayGas” Group;

- Corporate standard of HSE Competences Maintenance at JSC NC "KazMunayGas” Group;

- Corporate standard of Environmental Impact Assessment for a Planned Activity at JSC NC "KazMunayGas” Group;

- Health and Safety Policy of JSC NC "KazMunayGas";

- KazMunayGas Environmental Policy;

- KazMunayGas Policy on Safe Operation of Land Transport Vehicles

- JSC NC “KazMunayGas” Policy on Alcohol, Narcotic Drugs, Psychotropic Substances and Their Analogues;

- Regulations on Safe Operation of Vehicles at JSC NC "KazMunayGas";

- Working Instruction on Fire Safety in Administrative Buildings of JSC NC "KazMunayGas".

Contractors coordination

The Company is committed to improvement of criteria for selection of potential suppliers to guarantee high quality of work and complete transparency of the whole service cycle.

The Corporate Standard of Interaction with Contractors in the Field of Health, Safety and Environment at JSC NC “KazMunayGas” Group is a structural element of the Management System and includes the requirements to contracts with customers that should include an HSE Agreement for conformity with the HSE requirements and the penalties for failure to comply with the requirements, pre-mobilization audit of the machinery and equipment availability, audit of contractor personnel, and an HSE assessment of contractor. Besides, the Company regularly holds forums and meetings with potential service providers to discuss future partnerships and the HSE requirements of KMG.

The Standard requirements are mandatory for all contractors during supply/performance/rendering of GWS, including all associated operations and services at the production facilities of the KMG Group. At the KMG Group, an equivalent Standard is being developed and approved or the internal documents of subsidiaries and affiliates are amended to ensure conformity with the Standard, which will allow KMG to improve safety of its contractors and service provides, stakeholders, environmental protection, and improve its HSE indicators.

OCCUPATIONAL HEALTH AND SAFETY

Occupational health and safety policy of the KMG Group is based on commitments of the top management to health and safety and is aimed at engaging each employee in development of the safety culture. The management of the Company and its subsidiaries and affiliates follows the principles of zero tolerance towards losses and damage caused by accidents and emergencies, consumption of alcohol, narcotic drugs, psychotropic substances and their analogues, as well as by road traffic accidents. The Company’s commitment is to follow the national law alongside requirements of international and national standards.

Key indicators for 2020

Life and health of each employee is the top priority of the Company. We constantly strive to our goal, which is reduction of accidents to zero, that is, achieving 100 % safety. Each year the health an safety indicators are improving. The employees note that the Company ensures all safe working conditions and implements the highest standards for the employees to protect themselves, their colleagues and those around them. Nevertheless, there is still room for improvement. The company keep records within the Group and by contractor; contractor data are included in the accident rates.

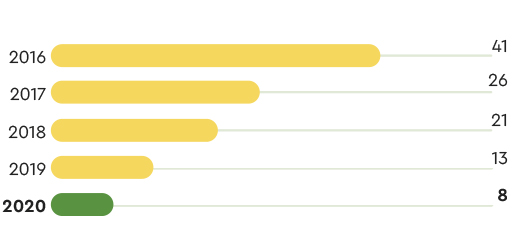

In 2020, no fatalities were registered at work, and this result has been achieved by KMG for the first time. Also, from the moment of KMG becoming a member of the International Association of Oil & Gas Producers (IOGP) in 2018, the injury and RTA rate of the KMG Group was lower than that of IOGP. Following the results of 2020, occupational accident rate reduced by 27 % compared to the previous year (from 41 cases in 2019 to 30 cases in 2020) and the number of injured employees reduced by 33 % (from 48 in 2019 to 32 injured people in 2020).

Number of road traffic accidents reduced by 66 % (from 44 accidents in 2019 to 15 in 2020) and the number of fires reduced by 40 % (from 10 fires in 2019 to 6 in 2020).

KEY INDICATORS H&S

|

Indicator |

UOM |

2018 |

2019 |

2020 |

Difference (between 2020 and 2019) |

% |

|

Accidents |

Accident |

48 |

41 |

30 |

-11 |

-27 |

|

People injured in accidents |

People |

50 |

48 |

32 |

-16 |

-33 |

|

Road traffic accidents |

Accident |

67 |

44 |

15 |

-29 |

-66 |

|

Fires |

Case |

12 |

10 |

6 |

-4 |

-40 |

ACCIDENT AND FATALITY RATE

|

Indicator* |

2018 |

2019 |

2020 |

IOGP*** |

|

Lost time incident rate, per mln man-hours |

0,32 |

0,31 |

0,25** |

0,24 |

|

Fatality rate, per 100 mln man-hours |

0,65 |

1,28 |

0,0 |

0,46 |

*Data on the Company's contractors are not included in the accident and fatality rates.

** The Company is in a continuous process to improve the efficiency of information disclosure in the field of sustainable development. As a result of the improvement of the methodology for recording man-hours worked in a number of the Group's companies, the LTIR coefficient for 2020 was updated and this explains its slight discrepancy with the information from the KMG Annual Report for 2020. In the next reporting period, an updated methodology for recording manhours worked will be used, which will avoid discrepancies with the Annual Report and the Sustainability Report.

*** Available IOGP metrics for 2019 (https://www.iogp.org/).

PRODUCTION PROCESS SAFETY MANAGEMENT

In 2020 KMG started its work in improvement of the production process safety to prevent major catastrophic incidents (process emergencies, incidents, and fatal accidents) at the Company. For these purposes, the Company has approved a corporate standard of production process safety management in the KMG group of companies (hereinafter – the Standard). The Standard establishes uniform requirements and effective approaches to maintain integrity of assets and process equipment, safe operational rules, standards, and procedures in compliance with the RoK statutory requirements and best work practices (IOGP, OSHA), identification of process risks, and application of corresponding measures to prevent and mitigate such risks.

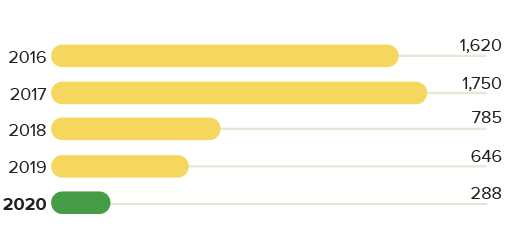

We annually control and monitor oil spills. The volume of oil spills for Exploration and Production reduced by 55 % in 2020 compared to the previous year and corresponds to 288 tonnes. The volume of the previous year was 646 tonnes. These results are the consequence of the ongoing program for improvement of reliability of upstream pipelines at the Company’s subsidiaries and affiliates of the Exploration and Production area aimed at replacement of the worn-out pipelines and protection of the lines from corrosion by inhibition.

The Company is working on reduction of faults and leaks in upstream pipelines by timely and quality diagnostics, reconstruction, replacement, inhibition, and cleaning of pipelines, aimed at improvement of integrity and reliability thereof.

The main cause of oil spills at the company are leaks in upstream pipelines caused by corrosion processes. The Company keeps working on reduction of faults and leaks in upstream pipelines by timely and quality diagnostics, reconstruction, replacement, inhibition, and cleaning of pipelines, aimed at improvement of integrity and reliability thereof.

OIL SPILLS (UPSTREAM) (TONNES)

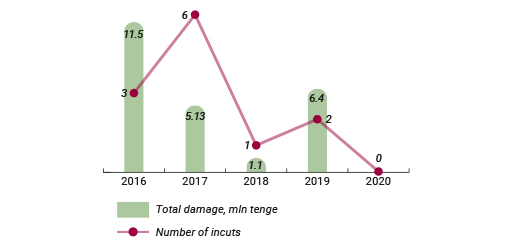

UNAUTHORIZED INCUTS

Closely cooperating with law-enforcement agencies, JSC “KazTransOil” could change the situation with unlawful incuts on the Company’s pipelines. Over the last several years the Company could reduce the number of unauthorized incuts: there were 3 unauthorized branches in 2016, 6 unlawful incuts in 2017, 1 in 2018, 2 incuts in 2019, and 0 incuts in 2020.

These results have been achieved in greater extent due to implementation of the following measures:

- stricter control over the monitoring of mobile groups using GPS systems and timely implementation of mobile groups’ visits and inspections of oil pipelines;

- oil pipeline security ensured by Optosense monitoring system.

Permanent preparedness for emergency oil spill response (EOSR) is our absolute priority.

Transport safety

The pilot project of Trip Management was launched at JSC Embamunaigas to improve transport safety and create the culture of safe driving and centralised digital platform.

The purpose of the project is to improve transport safety by creating a safe driving culture based on best international practices, modern digital solutions, and process automation. The project will ensure harmonisation of travel safety management requirements for all land transport operations, centralised control over the key metrics, and effective use of vehicles by introducing analytical reports and corporate indicators.

Further steps of the Trip Management project:

- by the end of 2021 – to connect the leased vehicles of JSC Embamunaigas to the single monitoring system;

- in 2022 – to employ the project solution at other subsidiaries and affiliates.

Fire safety

In order to reduce the risk of fire and damage to health of the employees and property, the subsidiaries and affiliates audited their fire-fighting, heating, and power systems, verified conformity and application of the standards and rules for operation of process equipment in compliance with the fire safety requirements and the internal regulations, with due regard to the nature of the production processes.

The contractors were also audited and receive corresponding recommendations. The Company developed a package of fire safety documentation (schedules plans, Inspection Report, operational fire-fighting plan, instructions, etc.). In accordance with the schedules, fire tactics trainings (FTT) are held at the sites with engagement of field fire-fighting equipment and the employees.

A range of preventive technical measures has been applied:

- maintenance and repair of the automated security and fire alarm systems, fire-fighting systems, and fire alert systems to maintain serviceability of the devices during operation, by carrying out periodic maintenance and technical inspection thereof and eliminating typical faults as set forth in the operational documentation and the standard operating procedures;

- fire safety audits;

- audits of emergency fire-fighting equipment, water supply systems, etc.

HSE digitalisation

- The project of Trip Management was initiated to improve transport safety and create the culture of safe driving and centralised digital platform.

- The project of Development of Environmental Monitoring Procedures was launched in the field of environmental protection. The purpose of the project is to increase transparency and efficiency, and to minimise error in performance of environmental accounting, analysis, control, and management processes at the KazMunayGas Group. A demo-version of the Information System has been presented on the basis of the pilot project at a producing organisation. A full-scale implementation of an automated information system of environmental monitoring at the KMG Group is planned for 2021 with commissioning of the system into commercial operation.

- Upgrade of HSE KMG information system

The HSE KMG health, safety, and environment information system comprises the following modules:

- Reporting – intended for preparing reports on HSE activities.

- Observation – intended for Behaviour-Based Safety Observation of operations and driving.

- Events – intended for planning internal audits and monitoring of implementation of the measures.

- Korgau – intended for identification and informing of unsafe conditions/behaviour/actions/hazardous case/factor, as well as for improvement of the health and safety system.

- HSE analysis – intended for surveying and collection of reports from the employees of the KMG Group.

- Accounting and investigations – intended fr accounting of all incidents and conducting incident investigations.

- Internal control and monitoring – intended for performing commission audits and identification of non-conformities.

- Analysis – intended for performing HSE analysis and automated visualisation of consolidated data. The HSE KMG system is planned for implementation within the entire KMG Group in 2021.

IMPROVEMENT OF WORKPLACE CULTURE AND HSE AWARENESSRISING ACTIVITIES:

During the reporting period, the following work was carried out:

- Analysis of incidents occurring during well service and workover and development of an Action Plan for improvement of production process safety during pulling and running operations of well servicing.

- Weekly distribution (68) of HSE brochures and check-lists among the subsidiaries and affiliates and the CC focused on prevention of occupational injuries, accidents, prevention of CVI, and continuous communication and advisory support to the professionals of the subsidiaries and affiliates.

- Videos on the following issues have been developed and distributed:

- lessons learned from pulling and running operations of well workover and servicing;

- lessons learned from the occurred road traffic accidents;

- emergency and crisis management system of KMG and response to all types of incidents (process accidents, fires, cyber-attacks, supply failures, and financial crises);

- industrial gymnastics at workplace.

- The subsidiaries and affiliates have been audited to ensure conformity with the HSE requirements, including preparation for the 2nd wave of CVI, with issues of corresponding improvement recommendations.

- To assess, analyse, and reduce HSE risks, the contractor companies of the KMG Group quarterly submit a report to the KMG Board of Directors on the non-conformities of the contractor companies, including penalties applied in the field of HSE.

- In fulfilment of the order given during the session of the Board of Directors of JSC NC “KazMunayGas” regarding prompt informing of the KMG BoD, instant reports on fires and major HSE incidents are sent to the BoD.

- Upon completion of investigation, the KMG BoD is provided with corresponding documents, including the investigation report, specifying he immediate and root causes, the extent of damage to property, copies of disciplinary orders against the employees who caused the incident, and the changes implemented following the incident investigation and to prevent similar incidents.

PRODUCTION SANITARY AND WORKPLACE HYGIENE

In accordance with the requirements of the RoK laws and the international standards in the field of occupational health and safety, production sanitary, and workplace hygiene, the Company has implemented an occupational health and workplace hygiene management system. The Company employs a proactive policy to protect its employees’ health and wellness, irrespective of the production process.

In 2020, There were 8 cases of fatalities not related to injuries 3 of which were contractors (without lethal cases of COVID-19 and pneumonia) reduced by 38 % compared to 2019.

NUMBER OF NON INJURY-RELATED FATALITIES

The system provides compliance assessment tools for establishing of health care facilities, risk management, and medical emergency response.

The key purposes of the Company’s system are as follows:

- establishing uniform requirements for production process management to maintain and improve the health of the employees;

- identification and reduction of risks (hazards and harmful occupational factors) by improving workplace hygiene and ergonomics, as well as production sanitary at workplaces;

- application of preventive controls based on the assessment of employee health risks and reduction thereof;

- promoting and encouraging healthy lifestyles for employees during and after working hours.

An evaluation of the Company’s system and development of measures to improve the system are carried out twice a year (every six months).

The Company regularly implements a set of measures to improve labour conditions and prevent occupational diseases at production facilities.

The KMG campaign of Heart Attack and Stroke Prevention is ongoing and is aimed at prevention o mortality among the employees due to heart diseases. The 10 Steps to Health initiative implementation is controlled and monitored along with the standard for arranging emergency medical aid at the company which specified the uniform requirements for rendering first aid to injured employees, equipping of first aid stations, and the contents of the emergency medical response plan.

In 2020, 55 employees of the KMG Corporate Centre were trained on rendering first aid.

To improve the efficiency of medical services to the employees of the Company (medical services and medical insurance), a draft Employee Health Management Concept has been developed along with an Action plan for 2021–2023 to ensure its stage-by-stage implementation.

A range of measure has been employed:

- a working group established;

- First Aid Procedure brochure developed;

- a video on workplace gymnastics produced;

- regular communication and advisory support was ensured for the subsidiaries and affiliates to prevent coronavirus infection and prepare the employees to respond to a worsening epidemiological situation;

- presentations on measures to prevent coronavirus infection for the employees of the KMG CC were arranged in cooperation with Mediker LLP;

- weekly distribution of brochures, check-lists, and videos among the subsidiaries and affiliates and the CC focused on prevention of CVI, continuous communication, and advisory support to the professionals of the subsidiaries and affiliates;

- interaction with the Committee for Quality Control and Safety of Goods and Services of the RoK Ministry of Health;

- arranging and coordination of PCR testing for the employees of the KMG CC;

- audit of the subsidiaries and affiliates to prepare for the 2nd wave of CVI (MMG, KTO (MNU) and the service companies – OSC, OTC, OCC) with provision of recommendations.

RESULTS OF HEALTH AND WORKPLACE HYGIENE MANAGEMENT SYSTEM ASSESSMENT

The results of the analysis of the industrial sanitation management system

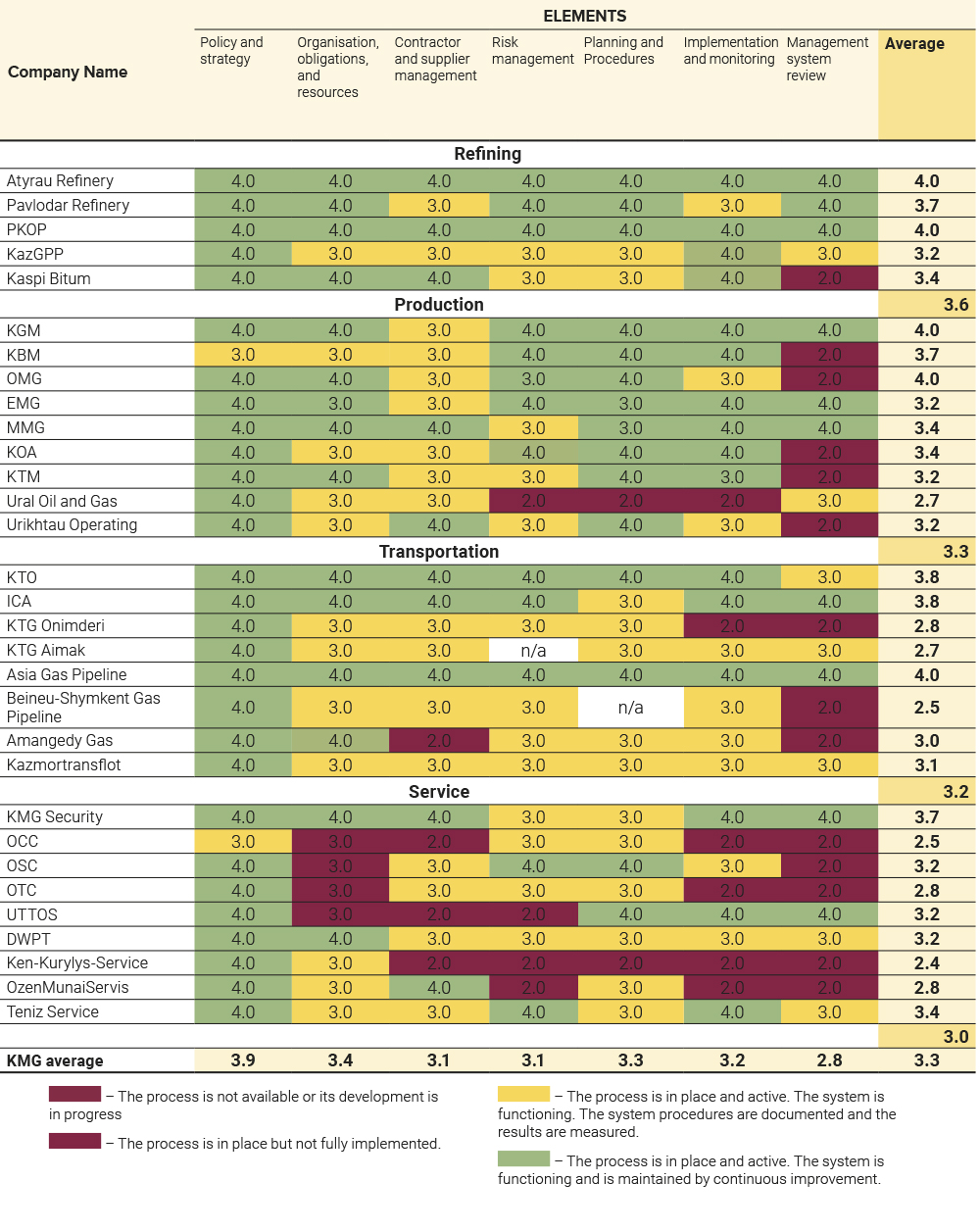

The analysis of performance indicators in the field of industrial sanitation includes a predictive assessment of the activities of subsidiaries and affiliates (GAP-analysis) at the level of implementation of health management systems, consisting of 7 elements, using assessment sheets (checklists).

Confirmation of the level of development of the health protection management system of subsidiaries and dependent companies is carried out through an audit, request for supporting documents.

The consolidated results of the KMG Group of Companies for the 2nd half of 2020 are shown in the table and displayed by business areas and for each subsidiary and dependent company separately. This allows you to use your goals for improvement, but also to see at what level of development they are in relation to subsidiaries and affiliates.

COVID-19 PANDEMIC RESPONSE – SAFETY AT PRODUCTION FACILITIES

The main achievement of the KMG Group in 2020 was prevention of the process shut-down during the CVI pandemic

As the pandemic started, within the shortest time the Company adapted to the new environment and applied a range of comprehensive measures to reduce the incidence, prevent and minimise the spread of CVI, and reduce the impact on production processes.

Procedures and directives, Action Plans, and Algorithms providing for three stages of reinforcement have been developed and implemented:

- Stage 1 – pre-quarantine measures;

- Stage 2 – maintenance of the quarantine measures and regimes;

- Stage 3 – escalation of measures to prevent incidences upon occurrence of infection sites.

In accordance with the approved plans and algorithms, the Company performed mass CVI testing, suspended all non-critical operations, limited business trips, prohibited mass events, switched the management system to a remote mode, increased duration of shifts for the shift personnel (from 7 to 14 days and from 14 to 28 days), demobilized all non-essential personnel from the production sites, and reduced the number of employees at the fields to the minimal possible to maintain continuity of production operations.

Substitute groups that are not involved in the working process and have no contact with the remaining personnel have been formed. Such substitute personnel is involved when the main personnel gets infected and is put to quarantine.

Quarantine accommodation of the employees has been arranged in the rotation camps and other designated locations, while all asymptomatic CVI carriers have been ensured proper self-isolation.

Operation of the KMG Crisis Management Team (hereinafter – the CMT) and crisis centres of the subsidiaries and affiliates (hereinafter – CC) was arranged effectively to exclude the impact of the pandemic on the production operations of the KMG subsidiaries and affiliates in all business areas.

The CMT and CC keep 24/7 monitoring of the epidemiological situation and the current situation to, if necessary, respond promptly and provide recommendations regarding corresponding measures.

Extensive work has been done to prepare for a second wave of the pandemic, taking into account all possible economic complications, including the development and implementation of necessary action plans.

The Company has employed comprehensive preventive and organisational measures of stricter sanitary and disinfection regime at all facilities of the KMG Group and, depending on the current situation, a range of epidemiological measures has been applied.

For the purposes of CVI prevention and compliance with the epidemiological measures, the Company carried out regular informative and awareness-rising work among the personnel and performed sanitation and disinfection.

To prevent infection cases and spread of CVI the following measures were suggested for implementation:

- compliance with the previously introduced algorithms (corrected with due regard to the experience received during the first wave) to reduce the risk of CVI spread and maintain epidemiological regime, stronger sanitation and disinfection, and other established sanitary requirements;

- critical business processes have been identified along with the options of rehabilitation thereof, as well as the list of essential personnel, suppliers, materials, and equipment;

- operational continuity and emergency recovery plans for critical business processes have been developed;

- readiness of the first aid services has been ensured along with addressing the possibilities of expansion in case of necessity of laboratory examination and arrangement of CVI vaccination;

- reserves of PPE (medical masks, respirators, gloves), dispensers, antiseptic and disinfectant solutions, as well as life-support equipment required for protection of the employees’ life and health have been ensured;

- the longer duration of rotation shifts has been preserved and the information and awareness-rising work among the employees has been intensified to ensure self-control and compliance with the sanitary standards, as well as the preventive measures (epidemiological vigilance) and social distancing;

- faultless supplies and prompt procurement of GWS have been planned in case of worsening of the epidemiological situation;

- continuous monitoring of CVI spread and cooperation with public and contractor medical services to implement preventive and quarantine measures and ensure collective response in case of worsening of the epidemiological situation.

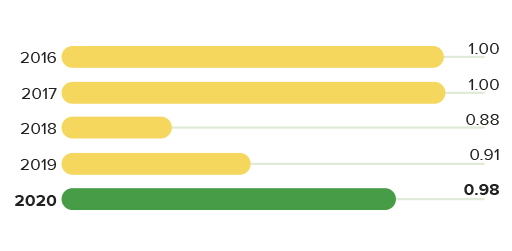

ENVIRONMENTAL PERFORMANCE

Production operations of the KMG Group is focused on minimisation of the environmental impact, sustainable use of natural resources and preservation of biodiversity. The environmental measures of 2020 allowed improving the environmental performance of the Company. Over the past years, part of the measures has been aimed at further increase of beneficial use of associated petroleum gas which resulted in improvement of the indicator up to 98 %. We also managed to reduce air emissions among the KMG Group. The Company utilizes its waste, including historical waste, and remediates the contaminated lands. The programme activities being implemented and planned will promote the reduction in water consumption from surface water sources and improvement of the waste water qualitative composition. Desalination plants in Mangystau region are in the process of construction.

KMG Green Office principles

The Green Office principles focus on use of all resources in an economical manner and maintaining environmental awareness. KMG works on implementation of the Green Office requirements that include measures for continuous improvement of working conditions, comfort, performance, design and architecture, green space expansion, and better recreational opportunities.

The following measures have been implemented as of today:

- installation of bins in offices, halls, lounge areas, and parking for separate waste collection: paper, plastic, glass, and metal;

- separate waste collection video with monthly results played on displays installed in lifts and lounge area of Izumrudnyi BC;

- a pop-up reminder to shut down computers and office equipment appearing on the employees’ displays by the end of a business day;

- a sticker with the reminder to preserve trees, minimise printing, use two-sided or black and white printing, print unofficial documents on the reserve side of recycled papers that contain no confidential information;

- to protect the employees from the harmful impact of computers, a pop-up window with a reminder to stand up for 5 minutes and do some exercises appears at 11 a.m. and 4.30 p.m.

- a pop-up reminder appearing on the displays of the employees at 10 a.m. and 3 p.m.:

“Wear a mask. Maintain social distancing. Wash and sanitise your hands frequently”; - draft calendar for 2021 concerning the ecology has been developed for the KMG employees;

- an awareness-rising campaign, internal distribution of posters, brochures, videos, and presentations about the Green Office concept;

- in the part of the introductory training, the adaptation programme for the new employees contains slides about the bins for separate collection of waste in the office etc.

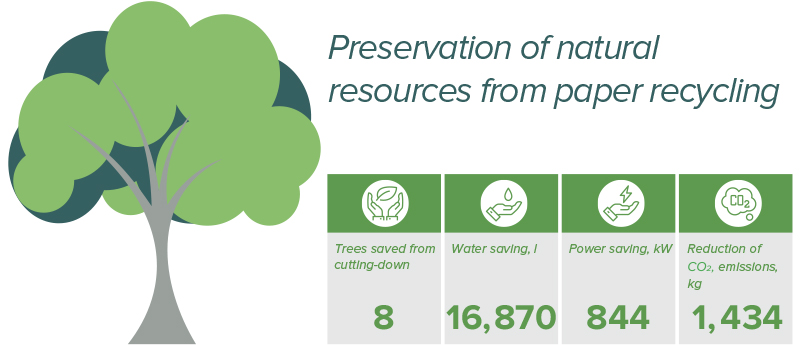

As part of the Green Office campaign, in 2020 the KMG Corporate Centre building collected 920 kg of recycled paper (561 kg of which was collected directly by KMG), 844 kg of plastic (KMG – 555 kg), 32 kg of glass and 45 kg of polyethylene, which preserved 8 trees from being cut down, saved 16,870 l of water and 844 kW of electric power, and reduced СО2 emissions by 1,434 kg.

Priority environmental projects

- Elimination of historical contamination as well as sources of negative environmental impact (idle wells, waste water ponds, landfills, and other production facilities).

- Reduction of emissions to the environment by improving process solutions, for instance, replacing fuel oil with fuel/natural gas (as fuel for process furnaces), use of new generation additives, green planting and landscaping in the territory of production facilities, replacement of equipment, expanding gas processing capacities, building gas processing plants, etc.

- Reduction of emissions of contaminating substances – the Tazalyq project: upgrade of the waste water treatment facilities of Atyrau Refinery LLP, remediation of the Rotten Draw evaporation ponds, and construction of desalination plants.

- Implementation of the Green Office principles, improvement of the environmental culture an rising of environmental awareness.

Environmental assessment of planned business activities

In accordance with the precaution principle (Principles 15 of Rio De Janeiro UN Declaration on Environment and Development, 1992) and in accordance with the requirements of the national and international laws, the Company performs environmental assessment of planned business activities at all stages of project life cycle – from declaration of intention to construction and operation design. We fully comply with the statutory requirements, regularly contact the local community representatives, and respect their opinion while planning and implementing our projects. Each design stage is accompanied by public hearings with participating of the concerned parties where all concerned parties get access to the EIA projects and all comments and suggestions are registered. All EIA projects of the KMG Group are subject to the state environmental expert review and are available to the public concerned on the Company’s official website and on the websites of local authorities throughout the entire life cycle of the project. In 2020, 14 meetings with the local community and public organisations were held, the Company arranged 29 public hearing sessions and media tours around some production facilities. Due to the limitations introduced in response to the emergency situation related to the COVID-19 pandemic, the number of offline public hearings was reduced.

In 2020, the Management board approved the Corporate Standard for Environmental Impact Assessment. The Standard specifies the corporate principles of the environmental impact assessment of the planned activity, regulates the activities of the KMG Group and contractors of the KMG Group, including design organisations whose activities relate to development of technical documentation and documents for environmental impact assessment, arrangement and performance of recording of public opinion regarding the environmental impact assessment documents, and obtaining of emission permits. The approval of the Standard by the KMG Board of Directors and its further implementation at the KMG subsidiaries and affiliates is expected in 2021.

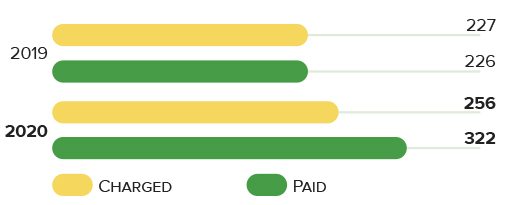

ENVIRONMENTAL PAYMENTS AND COSTS

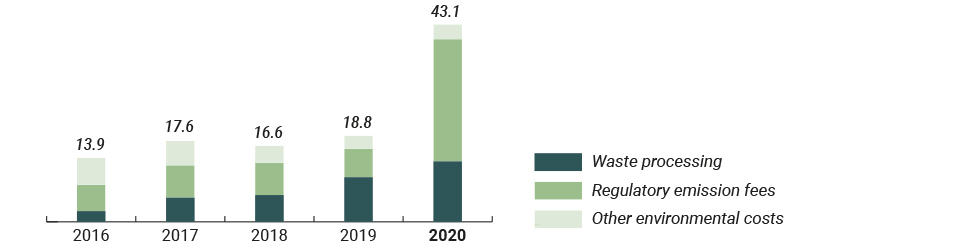

To effectively manage environmental risks, the Company is permanently improving its approaches to environmental management and allocates necessary resources for environmental protection.

Environmental costs include taxes on permitted emissions, cost of environmental activities, insurance, compensatory environmental measures, investments to prevent environmental impact, etc. We have expanded the budget for historical waste processing and remediation of the contaminated lands. The investment in waste processing has been increased by three times since 2015 and now makes more than one third of the environmental protection costs. At the same time, a reduction in air pollutant emission fees is observed. Environmental protection costs were equal to 43.1 bln tenge in 2020, which is 24 bln tenge more than in 2019. The major part of the costs is associated with oil refinery waste processing and implementation of cleaner technologies.

DYNAMICS OF ENVIRONMENTAL FEES AND COSTS, (KZT BLN)

SHUT-DOWN AND REMEDIATION OF SITES

As set forth in some contracts, in accordance with the laws and the regulatory documents, KMG is legally liable for dismantling and elimination of fixed assets and remediation of lands on each of its deposits. In particular, KMG obligations include gradual shutting-in of all unproductive wells and final cessation of operations, such as pipeline removal, destruction of buildings, and remediation of the contractual territories, as well as decommissioning of facilities and fulfilment of all obligations related to contamination of the environment at the production site.

The Company estimates the obligations related to disposal of assets separately for each of its contracts. As of December 31, 2020, the oil and gas asset disposal obligations were 66 bln tenge (as of December 31, 2019 – 54 bln tenge).

Trunk oil and gas pipelines

The KMG subsidiaries, JSC “KazTransOil” and JSC “Intergas Central Asia”, which is a subsidiary of JSC “KazTransGas”, are legally bound to remove the trunk pipeline upon termination of its operation and to further implement measures to rehabilitate the environment, including land remediation. The pipeline liquidation and land remediation reserve is estimated on he basis of the dismantling and remediation costs calculated by KMG. As of December 31, 2020, the book value of the KMG Group reserve for pipeline liquidation and land remediation was 114 bln tenge (as of 31 December 2019 – 100 bln tenge).

Use of energy resources and energy efficiency

The continuation of energy efficiency activities is seen by our Company as one of the environmental protection and productivity enhancement tasks. The Corporate Centre collects and analyses energy consumption and energy efficiency data, monitors the progress and identifies areas for improvement, performs a benchmarking against the previous period and the performance of peers (IOGP).

The Company’s activities in the field of energy conservation and energy efficiency are based on the methodology of ISO 50001 Energy Management Systems, which is the best generally recognised international practice for system management in this area.

Energy efficiency management using the EII energy intensity index assessment

In 2020, the Company started its work on operating processes energy efficiency management with the Total Quality Management (TQM) method. Along with that, the energy intensity index assessment (EII) practice developed by Solomon Associates has been employed at Atyrau Refinery, Pavlodar Refinery, and PKOP. The target is to reduce the total specific energy consumption inn 1-2 years by minimum 5%.

The concerned business units of the refineries were provided with the HSB Solomon Associates LLC methodology and other forms to make calculations for each major process and monitor the energy consumption structure of installations. Following the review of the recommendations given by Solomon Associates within the PEP project, a summary of the best energy efficiency management practices has been developed.

At this moment, the specialists of the production and engineering services at the refineries have adopted the methodology of EII energy intensity index assessment. The index assessment reports are sent for analysis to the Technical Development Department daily.

ENERGY CONSUMPTION

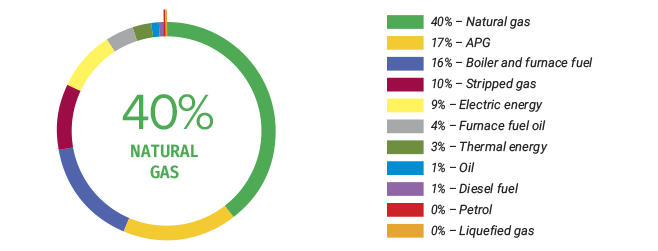

In total, 156.6 mln GJ of fuel and energy resources was consumed in 2020 (14 % less than in 2019), including 13.2 mln GJ of electric energy, 4.2 mln GJ of thermal energy, 1.5 mln GJ of motor fuel, and 137.7 mln GJ of boiler and furnace fuel. The energy consumption scope was distributed between the three business areas: Oil and Gas Production, Oil and Gas Transportation, and Oil and Gas Refining.

Reduced consumption of energy resources compared to 2019 is associated with reduction of the volume of transported gas and reduction of HCs production due to the pandemic. In 2020, the amount of energy generated by own facilities at the KMG Group was 406.0 mln kW of electric energy and 4,096 thous. Gcal of thermal energy.

Application of innovative technologies and use of renewable energy sources is a relatively new and promising trend in the oil and gas industry.

The renewable energy sources introduced at KTG in the previous years, in particular those at the subsidiaries of AGP and ICA: geothermal heat pumps of Waterkotte type; monocrystlline solar panels; closed cycle vapor turbogenerator - operate effectively. Generated renewable energy in the KMG Group is consumed for its own needs.

The total amount of the generated (produced) renewable energy in breakdown by sources at the KMG Group was as follows in 2020:

- Geothermal (thermal) energy generation by heat pumps 678.5 Gcal.

- Electric power generation by solar panels – 78,410 kW*h.

Electric power generation by solar panels of PKOP for outdoor lighting of the territory amounted to 211,000 kW*h in 2020.

CONSUMPTION OF ENERGY RESOURCES BY TYPES, %

ENERGY CONSUMPTION OUTSIDE THE ENTITY

Currently we keep records of energy consumption within the organisation only; therefore, energy consumption outside the organisation is not reflected in this report.

Reduction in energy consumption

The main strategic development areas of energy conservation and energy efficiency of the Group are upgrading process equipment, introducing energy saving technologies, optimising heating energy generation and consumption as well as developing own generation sources, including those with the use of raw gas.

In 2020, 55 measures were implemented to ensure energy conservation and energy efficiency. The planned annual saving of fuel and energy resources was 0.9 mln GJ, in natural units – 6.9 mln kW of power, 9.8 thous. tonnes of fuel gas, and 11,803 thous. cub. m of natural gas.

Examples of implemented measures that allowed to reduce energy and fuel consumption are modular complete power plants (Capstone) operating in an autonomous mode; complex automatic energy accounting system (ASCAE), the use of energy-saving lighting sources of light, etc.

Energy intensity

In 2020, specific energy consumption in the hydrocarbons production was on average 2.2 GJ per tonne of produced hydrocarbons at the KMG Group, which is 46 % higher compared to the International Association of Oil & Gas Producers (IOGP) indicator that was 1.5 GJ per tonne of produced hydrocarbons in 2019. In the oil production sector, the increase of specific consumption of energy resources is first of all associated with the increase of water cut at older deposits as higher water cut results in higher specific density of produced liquid and, correspondingly, higher demand for energy required to maintain mechanical production.

Specific energy consumption of Oil Refining was 4.3 GJ per tonne on average among the refineries in 2020.

Use of water resources

Since the Company performs its main activities in Central Asia where water is a valuable and scarce natural resource, KMG recognizes its responsibility towards the society and the environment and strives to ensure rational use of water resources.

KMG recognizes that the risks of a decrease in the amount of available water may have a negative impact on the Company’s operations in the form of increased operating costs. The scale of the potential impact is assessed as medium-to-high, and no assessment of the financial implications for the Group has been undertaken. The measures taken by the Company in response to the risk of exceeding the consumption of water resources in regions with a shortage of fresh water risks are reflected in 2019 CDP Water Security Questionnaire.

KMG officially declared its intention to contribute to preservation of the water resources of the Republic of Kazakhstan. At the Health, Safety & Environment Forum for General directors of KMG, Chairman of the Management Board A. Aidarbayev signed a personal Statement of Commitment to the rational management of water resources (eight water principles of KMG). This initiative has been supported by the Chief Executive Officers of the KMG subsidiaries and affiliates who signed equivalent statements on behalf of their companies. The signed statements are available on the official websites of the KMG Group.

The standard specifies the core principles of KMG in respect of use of water resources – the eight water principles, systematises the approach to water management at the KMG subsidiaries and affiliates, and assists in improving commitment of the managers and employees of the Company to sweet water preservation.

The Company deploys projects aimed at reduction of emissions and reduced water intake from natural sources.

Atyrau Refinery LLP

One of the main environmental measures is the TAZALYQ project that comprises upgrade and reconstruction of mechanical treatment facilities of Atyrau Refinery, reconstruction of the biological treatment facilities, and construction of a post-treatment unit, as well as the reconstruction of the evaporation fields and the canal for effluent treated to standard quality.

Therefore, rehabilitation of the evaporation fields suggests full cessation of waste water discharge to the ponds (860 ha owned by Atyrau Refinery) that will be dewatered and exclusion of the negative impact on ground water, flora, and fauna of Atyrau region.

The TAZALYQ project will also include construction of closed mechanical treatment facilities while implementation of modern processes will ensure treatment of water to standard quality.

Construction of desalination plants in Kenderli recreational area of Mangistau region

JSC Ozenmunaigas and KMG Engineering LLP have signed the Memorandum of Understanding and Cooperation with the Akimat of Zhanaozen. The signed document provides for conversion of the feasibility study developed by KMG Engineering LLP for construction of a desalination plant into a social project under the official instruction of Prime Minister of the Republic of Kazakhstan A. Mamin dated 18 September 2019. The desalination plant is planed to be constructed with the KMG funds in the territory of Kenderli recreational area of Mangistau region. The estimated capacity will be 50 thous. m3 of water per day.

JSC Karazhanbasmunai has faced the problem of water deficit as there are no potable water sources in the territory of the Karazhanbas field and the company needs large quantities of water to generate steam used as a thermal method of impact on oil reservoir by injection. As a result, the situation created a risk of oil production drop and associated losses.

A desalination plant construction-and-assembly works have been ongoing since September 2019 at JSC Karazhanbasmunai in Mangistau region of Kazakhstan. At the moment the construction is at the final stage. The desalination plant is designed to treat and dispose of reservoir water and supply with technical water in order to increase the reservoir recovery at Karazhanbas field by steam injection into the reservoir.

The plant is of high importance to the company because, in addition to desalination of water for steam generation, it will provide a solution for rational use of produced water. It will ensure improvement of the field development in terms of reservoir pressure maintenance.

In 2020, the CDP reports have been expended and the water management data was first published on the CDP website as part of the Water Security Questionnaire 2019. CDP Water Security Questionnaire 2019

Water footprint

The company conducts its activities in accordance with the national legislation of the Republic of Kazakhstan in the field of water resources management, best international practices, standards and regulatory legal acts. At the level of subsidiaries and affiliates, the Corporate Standard for Water Resources Management was introduced for the KMG group of companies, which defines 8 key “water” principles and establishes requirements for the activities of subsidiaries and affiliates in the field of water conservation and water consumption.

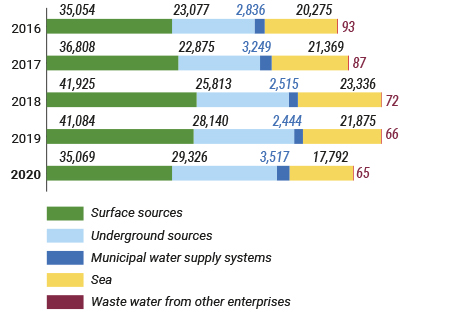

Total water intake of the KMG Group was 85.8 mln m3 in 2020 which is 8.3 % less compared to 2019 (in 2019 the Company consumed 93.6 mln m3 of water).

THE KMG GROUP WATER INTAKE WITH BREAKDOWN BY SOURCES, 85,769 THOUS. M3

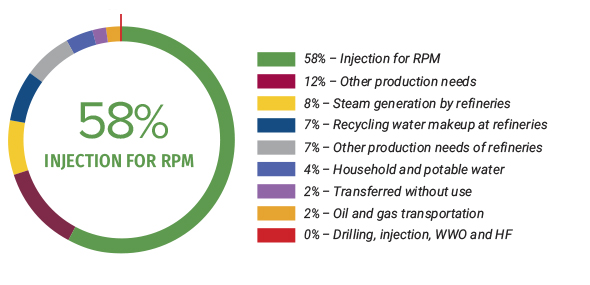

USE OF WATER RESOURCES BY TYPE OF OPERATIONS AT THE KMG GROUP IN 2020

In 2020, the Group discharged 10.45 mln m3 of waste water (normatively purified water), of which 9.83 m3 were discharged into the ponds, transferred to thirdparty organizations for the treatment of 0.62 m3 of wastewater. After waste water treatment in treatment facilities, the water treated to standard quality is discharged to specialised facilities: collection ponds, evaporation fields, and filtration fields. The enterprises that have no own storage facilities transfer waste water to specialised companies for treatment and discharge under the signed contracts.

After treatment, waste water is reused for vehicle washing, dust suppression, and fire-fighting systems. At this, significant volume of the treated waste water is recycled at the refineries only where 3.3 mln m3 of treated waste water was recycled. Such water is mostly used for makeup at recycling water units. The percentage of water recycling at the KMG plants was 21.6 % (from the total water intake in the Oil Refining area)

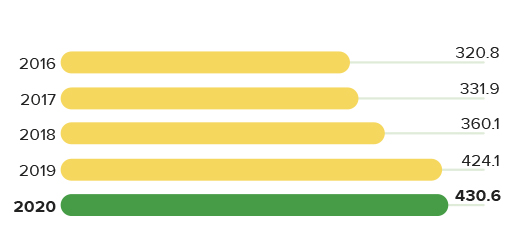

In total, the recycling water systems of the KMG refineries used (recirculated) 430 mln m3 of water.

CIRCULATION VOLUMES IN RECYCLING WATER SUPPLY SYSTEMS OF KMG REFINERIES: RECYCLING WATER, MLN M3

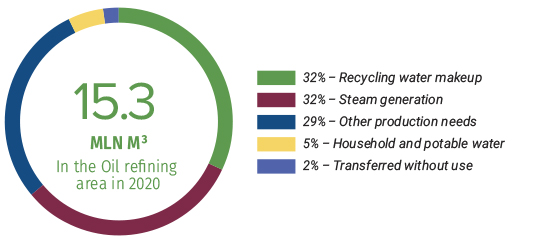

USE OF WATER RESOURCES BY TYPE OF OPERATIONS IN THE OIL REFINING AREA IN 2020

Oil production generates large volumes of so-called produced associated water: water-oil emulsion is drawn to surface, which is then separated into water and oil by gravity. After settling in this manner, water is injected to the reservoir.

In total, 99 % of 125 mln m3 of the associated water was re-injected to maintain reservoir pressure in 2020.

WATER INJECTED TO RESERVOIR TO MAINTAIN RESERVOIR PRESSURE PRODUCED ASSOCIATED WATER, MLN M3

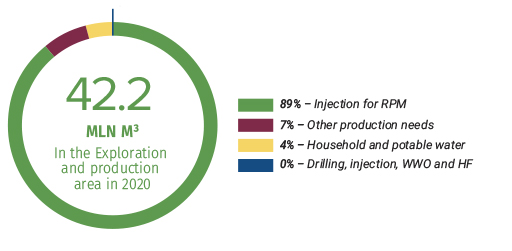

USE OF WATER RESOURCES BY TYPE OF OPERATIONS IN THE EXPLORATION AND PRODUCTION AREA IN 2020

The Company’s operations have the strongest impact on the water bodies of West Kazakhstan (the Ural and Kigach rivers, Kokzhide sands) that represent a special environmental, economic, historical, cultural and recreational value. The authorities perform regular environmental monitoring to prevent negative impact on sensitive ecosystems.

In November 2020, the Atyrau Refinery underwent a short shutdown of circulation pumps, which caused an excess of the concentration of suspended and organic matter (biosludge) at the point where the settler exits into the sand filter. The company took prompt measures to restore the operating mode of the installation, due to which this incident did not have a significant impact on the environment. Corrective measures have also been taken to ensure that such incidents do not recur in the future. More detailed information is presented at the link: https://www.kmg.kz/rus/press-centr/press-relizy/?cid=0&rid=799

Waste management

Regular accounting and monitoring of all waste is ensured at the production facilities of the KMG Group, including waste of contractors. The Company employs measures to reduce volume of waste generation and annually fund waste processing and (or) utilization of newly generated, accumulated, or historical waste.

Considering the current necessity to improve the environmental quality and to ensure environmental safety, KMG implements projects for reduction of accumulated waste volume, elimination of historical waste, and cleaning up of oil-contaminated areas.

In the period between 2016 and 2020 the Company cleaned up the fields with accumulated oil-containing waste: OMG cleaned up 5 fields, KBM – 1 field, MMG cleaned up and liquidated 10 fields, with transfer of the waste for utilization to specialised companies.

From the start of 2020, all newly generated waste of OMG, MMG, and KBM is transferred for utilization by third-party specialised companies without disposal on sites.

KTO is performing remediation of the disturbed lands in the territories of the Uzen – Atyrau – Samara trunk oil pipeline. 20.1 ha of disturbed lands have been remediated over 10 yeas, including 4 ha in 2020. The remediated lands are returned to the local executive authorities to be returned in economic use.

Under the Memorandum of Cooperation between the Ministry of Ecology, Geology and Natural Resources and KMG, efforts are being taken to dispose of waste and clean oil-contaminated land in the contract territories of MMG, OMG and KBM. Inventory checks of the contractual territories specified the characteristics of the wast and volume thereof, which was used as the basis for development and approval of corresponding remediation projects for of territories contaminated with oil in 2020. As parts of projects, safe and effective technologies for oil-containing waste utilization have been selected and recommended to the companies along with development of oil-contaminated land remediation. In total, OMG and MMG utilised 558,419 tonnes of historical waste and remediated the territories of disposal thereof in 2020. The operations under the Memorandum are planned to be completed by the end of 2024.

As part of the Company’s requirements and the “Waste Management” procurement-category strategy, work should be carried out on the contract territory without the removal of oil waste in order to minimize the impact on the environment and reduce transportation.

At the KMG Group, the total volume of the waste in circulation was 1,031.2 thous. tonnes in 2020, including 993.7 thous. tonnes of waste classified as “hazardous” and 37.5 thous. tonnes of “non-hazardous” waste correspondingly.

At this, the volume of the newly generated waste was 302.7 thous. tonnes and 95.5 % of that waste was either utilised or processed.

RATIO OF THE AMOUNT OF DISPOSED WASTE TO THE AMOUNT OF NEWLY GENERATED WASTE, T/T

END OF YEAR TO BEGINNING OF YEAR RATIO OF CONTAMINATED LAND AREA AT THE KMG GROUP, HA/HA

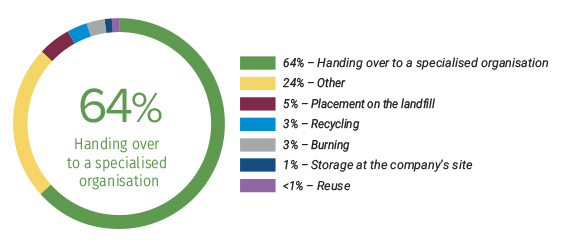

64 % of the waste is transferred for processing by specialised companies under contracts and 24 % of the waste was subject to bioconversion. Other major methods of waste management are recycling, disposal at landfills, and reusing.

In the process of waste disposal / recycling in the KMG group of companies, the total mass of hazardous waste transported in the KMG group of companies, the total mass of hazardous waste transported to the facilities of specialized enterprises in 2020 amounted to 631.8 thousand tons, for the reporting period of international transportation of waste, as well as imports and no hazardous waste was exported.

The company, when handling waste, ensures compliance with the environmental, sanitary and epidemiological requirements of the Republic of Kazakhstan, all transportation of hazardous waste is carried out in accordance with the rules for the carriage of dangerous goods by vehicles in the territory of the Republic of Kazakhstan.

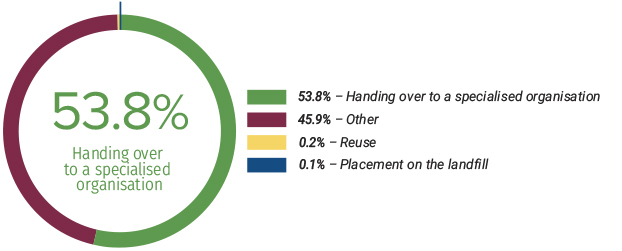

HAZARDOUS WASTE IN 2020 BY MANAGEMENT METHOD

NON-HAZARDOUS WASTE IN 2020 BY MANAGEMENT METHOD

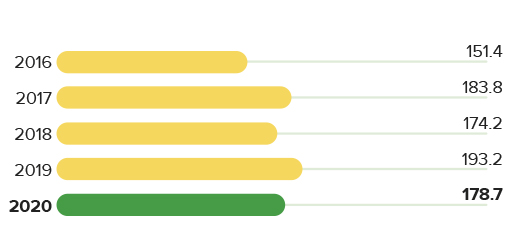

GENERATION OF DRILLING WASTE

The producing companies of the KMG Group generated 178.75 thous. tonnes of drilling waste in 2020, including: 29.41 thous. tonnes – waste drilling mud; 149.34 thous. tonnes – cuttings. All drilling waste of the KMG Group is transferred to specialised organizations for utilization. The organisations further utilise the waste by thermal and chemical methods, inertisation and bioconversion.

Measures to reduce the volume of drilling waste generation:

- rational use of raw materials and materials used in well drilling;

- reuse of drilling wastewater after separation of the solid phase (up to 20 % of the total).

|

|

thous. tonnes |

2016 |

2017 |

2018 |

2019 |

2020 |

|

Onshore projects |

Waste drilling mud |

44.24 |

49.50 |

37.05 |

59.24 |

29.41 |

|

Drilling sludge |

107.13 |

134.28 |

137.19 |

133.95 |

149.34 |

|

|

Offshore projects |

Waste drilling mud |

0 |

0.99 |

1.36 |

0 |

0 |

|

Drilling sludge |

0 |

1.06 |

0.81 |

0 |

0 |

OVERALL GENERATION OF DRILLING WASTE WITHIN KMG, THOUS. TONNES

The possibility of introducing a technology for treating drilling wastewater after the separation of the solid phase is being considered, which will reduce the volume of waste drilling fluids (in service subsidiaries and affiliates for drilling wells).

CONSERVATION OF BIODIVERSITY AND ENVIRONMENTAL MONITORING

Protected natural areas in the regions where we operate and the species of flora and fauna affected

North Caspian is the most productive part of the Caspian Sea. This part of the sea is rich with bioresources. There are 25 species of main commercial fish species, of which the most valued are sturgeons with 70-80 % of the global reserve living in the sea basin.

Eastern area of the North Caspian with deltas of Volga (within Kazakhstan) and Ural is a part of the State Conservation Area in the North Caspian. Wetlands of the North Caspian, particularly deltas of Volga, Ural and Emba, and the adjacent coast and the sea itself are essential for Eurasia and support millions of water birds and semiaquatic birds during nesting, moulting, seasonal migrations and wintering. One of the largest Eurasian flyways, the Siberia – Black Sea – Mediterranean Sea flyway, crosses the North Caspian.

According to the baseline studies, more than 70 bird species (including 5 rare species listed in the Red Book of Kazakhstan) migrate through open areas of the North-East Caspian 20-60 km away from the shore. The coastal areas are nesting home to little egret, Eurasian spoonbill, pelicans, whooper swan, ferruginous duck, and Pallas’s gull. Swamphen, white-tailed eagle and osprey are also observed flying.

Land cenoses are nesting grounds for 5 species listed in the Red Book of Kazakhstan. Steppe eagle is the most common one. As for rare birds, avocets, oystercatcher, little egret may be observed in these areas.

The only large marine mammal (pinnipeds) of the Caspian Sea is Caspian seal (Phoca caspica). It is an endemic mammal species. Seals are spread all across the Caspian Sea, although they vary in number in the North part depending on a season. Seasonal distribution of animals across the sea area is based on three main phases of the annual cycle: reproduction, moulting and feeding. Reproduction grounds are in the North Caspian, which freezes in winter. During feeding period from April till September, seals mainly stay in the Middle and South Caspian. In summer, only a few animals (about 30,000) remain in the North Caspian, the majority of population move to the deeper and colder South Caspian. They migrate to the North shallow waters in the late autumn, where water starts to freeze. The majority of population gathers in the North Caspian in October − November.

This area is essential to conserve biodiversity in Kazakhstan and the entire Eurasian continent and it needs to be continuously monitored and timely protected. From the very beginning of its operations in the North Caspian, KMG has focused on protection of environment of the region.

Republican Novinsky State Natural (Faunal) Reserve was established to create better conditions for reproduction of flora and fauna, including species listed in the Red Book of Kazakhstan. Protection status: a reserve.

Zhambyl is in the northern part of the Caspian Sea. The contract territory is within the Caspian Sea conservation area, and a part of it covers Novinsky Reserve, although industrial sites do not affect environmentally sensitive areas. This area has restrictions for production operations during the most environmentally sensitive period. Over the period under studies, there were no recorded abnormalities in natural conditions, environmental situation or unnatural factors which would cause concerns or require closer attention.

Isatay area is located in the northern part of the Caspian Sea, 45 km north of the coast of the Bozashy Peninsula in Mangistau region.

Dead Kultuk (Ustyurt) is the habitat of the most characteristic Caspian species – flamingo, which was common in the north-east in the past, and is still using this part of the sea, moulting and summer birds near Komsomolets bay and Dead Kultuk shor and Kaidak. Flamingo (Phoenicopterus roseus) is a locally nesting, decreasing species. It is the only specimen of its species in Kazakhstan fauna. Until now, the main nesting grounds in Kazakhstan included Tengiz lake, Chelkarteniz lake and north-eastern coast of the Caspian Sea.

Komsomolets bay, Dead Kultuk and Kaidak shors are still regularly used by thousands of birds to spend summer and moult. Birds from Central Kazakhstan fly through these areas and enlarge the local non-nesting population in April and August-September. Up to 35 thousand birds migrate through Komsomolets bay each year.

Mangistau region Mangistau Region has a vast system of designated nature conservation areas including Ustyurt State Nature Reserve and republican Kenderli-Kayasan Conservation Area, as well as 8 reserves and 1 regional natural park. Elaphe sauromates is one of the reptiles inhabiting the territory of Mangistau region that has been included in the Red Book of the Republic of Kazakhstan (2010). Afghan tortoise is a common, well spread species which is quite numerous in local areas of Mangistau Region, nevertheless, according to the Red List of International Union for Conservation of Nature (IUCN) it is a vulnerable species.

Kendirli-Kayasan protected area of national importance has been established to preserve the habitat and natural reproduction of MacQueen’s bustards and saker falcons. Established status: a conservation area, reserve/nature reserve, controlled area.

Ustyurt State Nature Reserve has the highest category of republican designated nature conservation areas. Ustyurt State Nature Reserve (USNR) was founded with the main goal of preserving the natural state of unique natural complexes, historical monuments, flora and fauna of Kazakhstan deserts. The Reserve is the main habitat of several species listed in the Red Book of Kazakhstan and/or International IUCN Red List: goitered gazelle, Ustyurt mountain sheep, caracal, honey badger, golden eagle, Eurasian eagle-owl, white scavenger vulture, chlamydotis, etc. According to the leading experts, the USNR meets the criteria of a UNESCO World Heritage Site and may be honoured as one in future to prove the highest level of recognition internationally.

A living Persian leopard was spotted for the first time in the entire history of Ustyurt State Nature Reserve in 2018. Formerly, leopard was only known in Kazakhstan because it was killed by human 3 times, including twice in Mangistau Region in 2007 and 2015. Leopards sometimes get to Mangistau from the neighbouring Turkmenistan, and considering the adequate food reserves (mountain sheep and goitered gazelle) they might possibly form a local population if they were not hunted by human and if the habitats were properly protected. There is at least 600 km between the Ustyurt Reserve to Kopetdag in Turkmenistan, where the leopard is known to live for a fact.

It should also be noted that the leopard is currently not listed in the fauna of Kazakhstan or the Red Book of the Republic of Kazakhstan. The USNR employees have already addressed the Forestry and Wildlife Committee of the Kazakhstan Ministry of Agriculture with the suggestion to immediately record the Persian leopards in the Red Book of Kazakhstan to ensure the necessary legal status for the species efficient protection.

Over the last decades, certain species of mammals that are new for the region were found: desert long-eared bat in West Ustyurt, lesser mouse-eared bat and common noctule in North Ustyurt, honey badger in South-Western Ustyurt, golden jackal in Mangyshlak plains and Karagiye Depression, raccoon dog. Striped hyena was encountered in West Ustyurt and signs of Indian crested porcupine were observed, which has not been recorded in the area for more than 40 years.

Kansu area of Karakiya district in Mangistau region lies partially within the territory of Kendirli-Kayasan protected area and borders with Ustyurt State Nature Reserve (2 km of the buffer zone from the borders of the area). No geologic exploration work was carried out on the site in 2016. Due to high geological, environmental risks and non-profitability, KMG made a decision to exit the project. In 2019, the procedure for return of the contract territory to the government started.

Samtyr area Since 2018 JSC NC “KazMunayGas” has owned 50 % of Samtyr LLP located in Mangistau region. It is located within South-Ustyurt sedimentation basin immediately next to Uzen, Shakhpaty, and Dzhel fields.

Kokzhide-Kumzhargan, Local State Nature Reserve. This reserve accommodates two sites of the republican nature reserve fund: Kokzhide Sands and Kokzhide Groundwater, which are included in the List of Republican and International Geological Sites of the State Nature Reserve Fund.

Urikhtau, Alibekmola and Kozhasay fields are located in Mugalzhar District of Aktobe Region, Kazakhstan. North-western part of the contract territory within Urikhtau field lays within the Kokzhide Sands, the fields also border Kozhide−Kumzhargan Local State Nature Reserve. To avoid groundwater pollution, environment is being regularly monitored both within the Group operations footprint and near the Kokzhide Sands adjoining the contract territory.

Karazhambas field is in the north-western part of Buzachi Peninsula, within Caspian Depression, in the territory bordering the Caspian Sea on the west. The field’s west borders the State Nature Conservation Area of the North Caspian. Industrial environmental monitoring includes bi-annual flora and fauna monitoring.

PRODUCTION SITES LOCATED WITHIN THE BOARDERS OR NEXT TO NATURE RESERVES

|

Type DNCA |

Within |

Adjacent borders |

Outside |

|

Category IUCN I-IV |

0 |

0 |

Kansu |

|

Category IUCN V-VI |

Zhambyl Satpayev Isatay Dead Kultuk (Ustyurt) |

Zhambyl Urikhtau |

Alibekmola Kozhasai Karazhambas Rozhkovskoe |

|

World heritage sites |

- |

- |

- |

|

Ramsar lands |

- |

- |

- |

OUR CONTRIBUTION TO PROTECTION OF BIODIVERSITY IN 2020

Number and percentage of major operating sites where biodiversity risk has been assessed and monitored in 2020

Baseline environmental studies, drilling, and well testing have been performed in the areas located in the state reserve territory in the north of the Caspian Sea. There are currently no significant man-made effects in these regions, which would restrict free movement of wild animals and birds within their habitats. During drilling operations the following activities have environmental impacts: drilling rig installation, well drilling and testing, navigation. Among impact factors are increased concentrations of suspended solids in water during offshore construction, disturbance of natural structure of bottom deposits due to intensive navigation among other things, physical effects of noise.

Construction of an appraisal well in East Urikhtau field and an appraisal directional well in South Urikhtau field has started in Urikhtau, which shares borders with designated nature conservation lands. Groundwater impact factor is the well drilling which may pollute groundwater. Pollutants may also enter groundwater with infiltrating precipitations from the surface of industrial and domestic waste accumulations, oil-contaminated areas, oil and produced water storage areas. In this respect, KMG implements certain measures to protect groundwater and prevent it from being polluted, littered or depleted. Well design isolates groundwater reservoir by running a casing down to 80-85 meters, and regular observations are performed over occurrence, level and quality of groundwater in currently and potentially polluted areas.

The Company performs continuous environmental monitoring of abandoned wells and hydrology, hydrochemistry, hydrobiology, and ichthyology researches as part of compensation for the unavoidable damage to fish resources caused by operations. Zhambyl Petroleum LLP invested 72.8 mln tenge in research work to compensate for the damage to fish in 2020. KMG System&Services LKP released 94,600 starry sturgeon underyearlings in the Ural river in 2020.

|

|

|

Onshore operations |

Offshore operations |

||

|

|

2019 |

2020 |

2019 |

2020 |

|

|

Sites where biodiversity is covered in EIA or an equivalent document (%) |

100 |

100 |

100 |

100 |

|

|

Sites where environmental monitoring is performed regularly (%) |

100 |

100 |

100 |

100 |

|

|

Parts with abandoned wells where abandoned wells are regularly monitored (%) |

100 |

100 |

100 |

100 |

|

Another impact factor of industrial development of the territory on biodiversity is power transmission lines which pose major danger for birds. The network of overhead power lines is constantly expanding and invades natural bird habitats, often causing their mass death. This is of special concern for predatory birds living in forest-free steppes and semi-deserts where overhead line pylons are the most attractive for the birds to sit on.

Identification and research of electrical installation areas of high risk for birds is performed as part of special researches or as part of industrial environmental control. To exclude electrocution of birds on overhead power lines (6-10 kV OPL), special polymer bird protective devices (BPD) are installed on the lines. This type of BPD, despite being commonly used abroad, is only being introduced in operation in Kazakhstan. The advantage of this device is use of non-conducting material for manufacturing of all BPD parts. Installation of the BPD requires no preliminary complex preparation (welding, crossbar drilling, etc.). At the same time, insulation of live wire ensures that hazardous short-circuits involving birds are avoided.

For instance, KTO replaces the used АС-50/8 steel-reinforced aluminium cable with self-supported SPW-3 protected wire during overhauls of 6-10 kV overhead lines. The performed overhauls included installation of 223 km of SPW-3 wire. Use of self-supported protected wire ensures insulation of birds from exposed live parts, thus protecting birds from electrocution and death.

Each of us can contribute to conservation of biodiversity in our country by following simple rules:

- Do not litter streets and nature;

- Care for environment;

- Do not engage in illegal hunting and fishing;

- Focus on conservation of biodiversity when planning environmental activities;

- Report violations of environmental law by legal entities and individuals to authorized officers and to hse@kmg.kz;

- Record red-book listed animals and plants in an area by taking photos and tagging locations, and send to hse@kmg.kz;

- Participate in campaigns and programmes to preserve biodiversity in Kazakhstan;

- Send your initiatives, ideas and projects to hse@kmg.kz.

PREVENTION OF SPILLS ON WATERS

Permanent preparedness for emergency oil spill response (EOSR) is our absolute priority.

The Caspian Sea is a unique natural object with fragile ecosystem which is particularly sensitive to oil pollution due to its enclosed nature. We set high requirements to environmental safety during offshore oil operations: any work is preceded by baseline environmental studies in the contractual territories and assessment of our potential social and environmental impact. We also monitor the impact, emissions, and accidents – both during and after operations.

Prior to commencement of offshore drilling operations, we ensure permanent preparedness to respond to any possible emergency oil spills. Upon termination of the operations, we continue with ongoing environmental monitoring of the abandoned wells. Monitoring of abandoned wells in contractual territories includes monitoring over the following: air quality, sea water and sediment pollution, biodiversity condition, as well as laboratory and analytical work, photo and video recording of the abandoned wellheads.

In our offshore operations, we strictly adhere to the following principles:

- Strict compliance with the design solutions

- Zero discharge principle – all waste and waste water is taken to the shore

- Equipping all facilities with fish protection devices and absence of bilge water

- Prohibition of any production operations during the breeding season – from 1 April through 15 July

- Prohibition of fishing on production vessels

- Prohibition of well testing and burning of raw hydrocarbons at night time

- Compliance with the special operation mode

Zhambyl Petroleum LLP has signed a contract with the consortium comprising KMG Systems & Services LLP, Kazmortransflot LLP, and Republican State Enterprise on the Right of Economic Use “Professional Militarized Emergency Rescue Service” to receive services of emergency oil spill response (hereinafter – EOSR). In the period of development well construction, the EOSR vessels stay within 500 meters from Caspian Explorer SSDR.

The initiative of volunteering for emergency oil spill response

Taking into account the seriousness and importance of a thing like volunteering for emergency oil spill response (hereinafter – EOSR), KMG Systems&Services LLP initiated development and implementation of the Volunteering Programme for EOSR in Atyrau and Mangistau regions (hereinafter – the Programme). The Programme includes all volunteering aspects such as legal aspects of volunteering in the Republic of Kazakhstan and other countries, how to involve volunteers, how to register and manage volunteers before and during EOSR, it also classifies volunteers and suitable tasks, rights and obligations of volunteers and basic personal safety for volunteers. The Programme specifies the tasks that need to be completed before a spill (preparatory stage) and oil spill response action (operating stage).

The key purpose of the project is to ensure transferring knowledge and training to volunteers in the basics of emergency oil spill response (EOSR) and wildlife rescuing.

As part of the project, a training video on “Transfer of basic knowledge in wildlife rescuing during emergency oil spill response operations”.

The target audience of the course are both potential volunteers for EOSR and other concerned parties, including representatives of authorities, specialists of companies engaged in offshore oil operations, etc.

The video course will teach you about personal safety of a volunteer, a volunteer’s rights and obligations, the impact of oil spills on wildlife, as well as the types of operations volunteers might be involved in during wildlife rescuing operations. It is essential to understand that volunteers cannot be engaged in all wildlife rescuing operations as safe and effective work requires special training and experience in such operations. The course shows which types of work a volunteer can do independently and which can only be performed with expert guidance only.

Everyone who is interested may filll in a questionnaire on the corporate website of KMG Systems&Services LLP for further 2-day training in Atyrau and Aktau in the basics of oil spill response.

Climate change and air quality

We make it our highest priority to minimise our impact on environment through compliance with environmental law, rational use of natural resources and continuous improvement of our environmental activities. Our priorities include careful and rational use of natural resources, minimisation of environmental risks. Target Programmes are intended to reduce raw gas flaring, develop green energy based on renewable energy resources and generally increase energy efficiency.

The KMG Corporate Centre manages activities of subsidiaries and associated companies with regard to greenhouse gas and pollutant atmospheric emissions, monitors that all permits for activities are obtained in due time, such as emissions permit, greenhouse gas quota, raw gas flaring permit.

Atmospheric impact minimisation programmes include raw gas development and refining programmes for production sector, oil refineries upgrade programme, application of the latest available technologies in the construction of new transportation facilities, etc. Gradual implementation of these programmes will result in reduced pollutant and greenhouse gas emissions into the air, increased benefits from using raw gas.

The KMG Group has an effective Emission Management Policy specifying the key principles of operational management to reduce the harmful impact on the air:

- Operating in strict compliance with the law and other Company commitments;