HSE management goals are directly related to the Company Development Strategy. The KMG-2028 strategy includes strategic initiatives to improve environmental liability. Environmental priorities of the Company include management of greenhouse gases and reduction of flaring, water resource management, production waste management, land reclamation and increasing energy efficiency.

Based on the Strategy priorities, in 2019, the Company approved the Environmental Policy. Management of KMG and its subsidiaries and associated companies exercises zero tolerance to losses and damage due to environmental pollution. For instance, it is the first time that the Policy addresses such environmental aspects as climate, biodiversity, commitments to apply additional risk assessment for environmentally valuable sites, reclamation of polluted land, ensuring integrity of pipelines.

Principle 7. Environment: Businesses should support a precautionary approach to environmental challenges

Principle 8. Environment: Businesses should undertake initiatives to promote greater environmental responsibility

Principle 9. Environment: Businesses should encourage the development and diffusion of environmentally friendly technologies

In 2015, KMG supported the World Bank’s GGFR initiative intended to achieve zero regular associated petroleum gas (APG) flaring by 2030. As part of implementation of the above initiative, in 2019, KMG approved the Emissions Management Policy. The Policy consists of eight key principles, of which six directly concern climate change, and is aimed at zero regular flaring.

The Group implements the KMG Safety and Environment Improvement Roadmap 2020, which includes basic strategic environment and sustainability initiatives. Each year, the Company builds new disposal facilities, upgrades the existing units, invests in construction of pipelines and infrastructure, e.g. construction of the gas treatment unit package, Saryarka trunk gas pipeline.

Health, safety and environment management system in KMG is based on best international practices and recommendations of the International Association of Oil & Gas Producers: IOGP, ISO 14000 and ISO 45001. The System consists of 10 areas and is supported by fundamental principles of leadership, achievement of goals, risk management and continuous improvement.

Since 2006, the quality, environment, health and safety management system as required by ISO 9001, ISO 14001 and OHSAS 18001 has been implemented in the Company’s subsidiaries and associated companies. The entities with substantial energy consumption levels are ISO 50001 certified. Management systems are regularly verified to be effective by independent auditors.

To improve safety management, subsidiaries and associated companies of KMG are scheduled to certify their health and safety management systems under ISO 45001:2018, which supersedes OHSAS 18001:2007 by 2021.

The Company has three levels of HSE management system

1.KMG Board of Directors

2.HSE Committee at the KMG Management Board level

3.EHS Committees of subsidiaries and associated companies.

Since 2019, the Health, Safety and Environment Committee has been active at Samruk-Kazyna level.

The HSE reports are presented monthly at the KMG Board of Directors meetings, detailed information reports are submitted to meetings of the HSE and Sustainable Development Committee of the KMG Board of Directors.

The Company is committed to improvement of the criteria for selection of potential suppliers to guarantee high quality of work and complete transparency of the whole service cycle. Corporate HSE contractor’s coordination standard in the KMG Group is an element of the Management System and includes requirements for contracts, including HSE agreements, HSE requirements and penalties for violation of such requirements, pre-mobilisation audit to ensure that contractor’s machinery and equipment, personnel are ready, assessment of the contractor’s HSE performance. Moreover, the Company regularly holds forums, meetings with potential service providers to discuss future partnership and HSE requirements applicable in KMG.

The KMG Group Health and Safety Policy is based on leadership and top management commitment to health and safety, and is intended to get each employee involved in development of the safety culture. Management of the Company and its subsidiaries and associated companies exercises zero tolerance to losses and damage due to accidents and incidents, abuse of alcohol, drugs, psychotropic and their equivalents, road traffic accidents. The Company’s commitment is to follow the national law alongside requirements of international and national standards.

The first SPE (Society of Petroleum Engineers) Caspian HSE Symposium included in the official Forum programme sponsored by KMG and supported by IOGP (International Association of Oil & Gas Producers) was held in September 2019 in Nur-Sultan as a part of the Kazakhstan Energy Week 2019. The Symposium was dedicated to health, safety, environment and social responsibility. Today, HSE in KMG goes hand in hand with increase in efficiency, cost cutting, increased performance, profitability improvement, team motivation and social responsibility of the environment all oil and gas companies operate in. Having come a challenging way of formation and growth, we have finally moved from being a company, which bases its operations on the law only to become a proactive company, which applies best international and industrial HSE practices.

Getting to Zero was the topic of the Symposium, and concentrated on creating value/zero incident approach, active introduction of innovations and learning lessons in the developing business environment. We have explored how our industry may respond to and affect the emerging technical and social challenges in a reliable and sustainable manner. Moreover, we have studied opportunities offered by digitalisation and automation, and how our industry may use benefits and integrate innovations like these to supplement HSE, rather than to compromise it.

The raised topics also included rational use of environmental resources and sustainable development: management of water resources, waste handling, emissions management, community investments and longevity of social projects, human welfare, and how national oil companies should stand their ground to hold their rightful place in the energy mix.

The Symposium also addressed absolute leadership and safety culture, standards and norms, which form thinking, attitude and behaviour of employees. Workplace safety culture is defined by “how we work when we are not being watched”. We covered the definition of human factor as a new cause-effect factor for the industry, which sparked interest and raised many questions from the majority of attendees.

The Symposium brought together over 300 local, regional and international experts and practitioners from the Upstream, Midstream and Downstream sectors to share best practices, progressive approaches and innovative solutions to enhance HSE performance.

Pilot project “Near Miss Reporting/Qorgau Card” was launched in 2019 and focused on detection and correction of unsafe behaviour. The Near Miss Reporting Programme will be aimed to define unsafe working conditions. This Programme will involve employees of all levels and will enable them to communicate their concerns, challenges and suggestions.

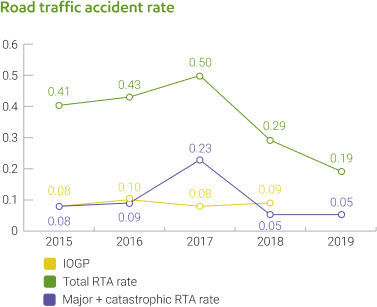

Review of the Land Transport Safety Management System revealed three improvement areas: training and qualification of drivers, vehicle monitoring system, GPS and journey management system. Resolution of the KMG Modernisation Board of 23 October 2019 approved initiation of Journey Management project under KMG Digital Transformation Programme to improve transport safety and enforce procedural framework, establish consistent requirements in accordance with the KMG Transport Safety Policy.

The Project will be focused on increasing transport safety by creating safe driving culture based on best international practices, and implementing state-of-art digital solutions and process automation. The Project will be implemented in 2020–2022. The Project will allow establishing consistent requirements for journey safety management for all land transportation, introduce centralised monitoring of the main metrics and use vehicles efficiently through implementation of analytical reports and corporate indicators

Getting to Zero are not just words, it is a particular, clear and tangible goal that we all, as representatives of the oil and gas sector, are facing today. This is what we all need to work on, each in his/her own company, yet together. This is what we need to improve continuously and always search for new methods. All to achieve the ultimate workplace safety. Because the priority of human life and health is higher than any performance figures.

Caring about safety of employees starts out small: from improving working conditions and workplaces. KazMunayGas strives for meeting the highest safety standards; we do our best to make this culture wax in size and strength.

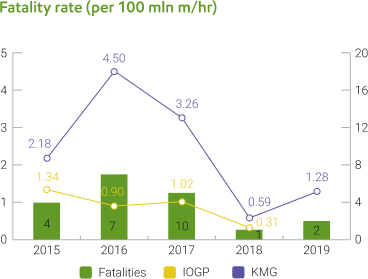

Life and health of our people is our priority, that is why we will never stop working on our goal to achieve zero accidents, i.e. 100% safety. In the past 5 years, we have achieved considerable improvements in our health and safety performance. Our employees note how safe working conditions are created and how the highest standards are introduced to protect themselves, their colleagues and people around. However, we still have room for improvement. To our great regret, in the second half of 2019, we lost two of our employees through a road traffic accident and fire.

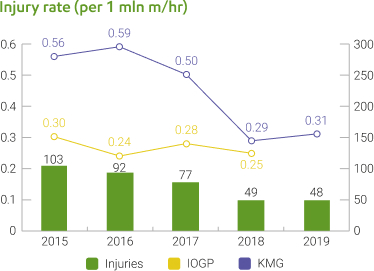

• Injury rate: 0.31 (compared to 0.32 in 2018)

• Violations of the Golden Rules reduced by 23% as compared to 2018 (47/36)

• Arm and hand injuries reduced by 57% as compared to 2018 (21/9)

• The KMG CC audit plan was fulfilled (15 out of 15 SACs and facilities)

• Ten corporate HSE guidelines were approved.

KMG and its SACs manage occupational health and workplace hygiene issues in compliance with the Kazakhstan laws: RK Labour Code, Health Code, Sanitary Rules and Instructions as well as international requirements for occupational health and workplace hygiene.

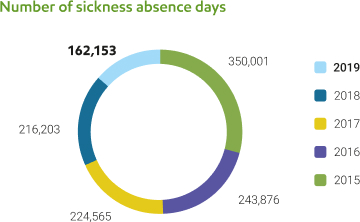

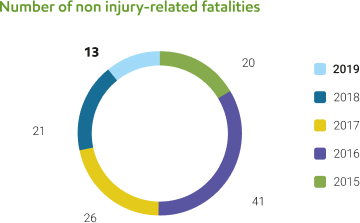

In 2019, the number of sickness absence days of SAC employees was 162,153, which is 54,050 days or 24.9% less than in 2018. The non-occupational death rate for SAC employees decreased by 8 or 38.0% compared to 2018.

As part of implementation of the KMG Safety and Environment Improvement Roadmap 2020 as approved by the Resolution of the Management Board dated 27.09.2016 (Minutes No. 39), the KMG corporate health improvement programmes aimed first of all at reducing the burden of disease and non-occupational death rate among employees are being gradually implemented.

To ensure improvement and efficiency of the occupational health and workplace hygiene management, the following activities were carried out:

• Comprehensive audits of SACs with the involvement of SAC specialists included into the KMG occupational health and workplace hygiene functional group, for sharing experience purposes.

• Emergency first aid drills at EMG, KGM, KTO and Atyrau Refinery with the involvement of a specialised healthcare provider and government emergency response agencies.

• A training (seminar) for the SAC occupational health and workplace hygiene specialists in “Occupational Pathology and Workplace Conditions Compliance Certification” (Atyrau) was organised and conducted.

Activities in the following priority areas are scheduled for 2020:

1.Introducing the key corporate document — KMG Group Occupational Health and Workplace Hygiene Corporate Standard, including tools to assess the current level of the management system, inter alia, to assess risks, equipment and facilities at first aid stations, preparedness for emergency medical response. Such tools will serve as a basis for developing management system improvement measures.

2.Conducting audits at SACs to control and monitor occupational health and workplace hygiene.

3.Organising an emergency first aid drill within the KMG Group at the premises of MMG, ICA, POCR, KBM.

Organising and conducting a training (seminar) for the SAC occupational health and workplace hygiene specialists.

In 2019, a benchmark of the Tier 1 Process Safety Event Rate (PSER) was performed for KMG’s process safety against international oil producers that are members of the International Association of Oil & Gas Producers (IOGP). This rate for the IOGP Group is 0.17, which is much lower than KMG’s rate for the Exploration and Production business line being 1.76.

In the meantime, in 2019, the volume of oil spills for Exploration and Production increased by 15% compared to the previous year and amounted to 646 tonnes, while the last year’s figure was 741 tonnes. These are the results of continuing implementation of the Exploration and Production SACs field pipeline reliability improvement programmes aimed at worn-out pipeline replacement and pipeline corrosion protection through inhibition. In 2019, 3 man-made non-fatal accidents occurred at the Company’s production facilities. By their nature, these accidents are classified as well out-of-control with subsequent gas and water ingress, and in one case ignition took place.

On 13 March 2019, man-made gas and water ingress occurred in the process of well construction on a problem site of Kalamkas Field. From 13 to 24 March, specialists were engaged in well flushing with weighted drilling mud as well as remedial cementing to eliminate gas springs. On 25 March, in spite of the efforts taken, the gas and water blow-out source combusted. On 28 March 2019, the gas spring ignition source extinguished spontaneously. No fatalities or injuries were reported. The associated water spill area was about 1.5 km2 . The distance to the Caspian Sea protection dyke is 4.5 km, which prevents associated water spilling into the sea. The population was not affected, as the field is remote from settlements (the nearest Shebir village is more than 70 km away). Government authorities collected out of schedule the air and soil samples at the border of the field sanitary protection zone and sea water samples from the Caspian Sea near the field. No excess of maximum permissible concentrations of pollutants was found in the samples collected.

In August and October 2019, two cases of gas and water ingress and gas ingress with subsequent underground equipment blowout occurred in Atyrau region.

The Company performed a range of recovery operations. The analysis of the lessons learnt enabled elaboration of a plan of remedial actions to ensure the quality and safety of further well drilling.

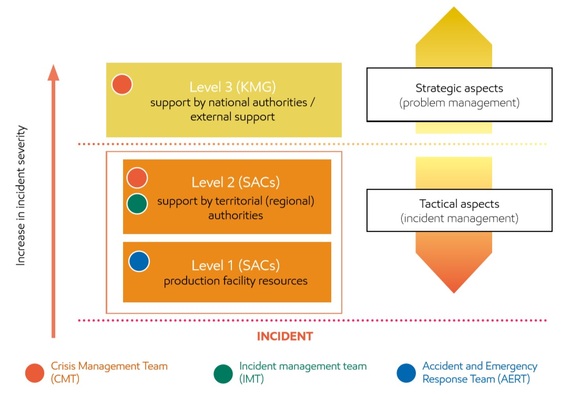

In order to ensure prompt response, prevent the escalation of possible crisis situations, minimise the severity of consequences and probable loss, if any, the Crisis Management System was introduced. The KazMunayGas Group employs a three-level management system that ensures the escalation of incident response from the level of a production facility and subsidiary up to the level of strategic crisis management by the corporate centre. In 2019, the first drill was held by the Crisis Management Team. In-house training in the crisis management system is conducted within SACs.

We are aware of our responsibility to the society for the efficient use of natural resources and preservation of favourable environmental conditions within our footprint to take extensive measures aimed at reducing and minimising our environmental impact.

KMG ranked first in the Eurasian Environmental Transparency Rating of Oil and Gas Companies 2019 organised by the World Wide Fund for Nature (WWF) of Russia and the CREON Group in partnership with the United Nations Environment Programme (UNEP), CREON Capital and the National Rating Agency (NRA). By taking the lead for the third year in a row, the Company confirmed its title of Kazakhstan’s most environmentally transparent and responsible company.

The purpose of the rating is to promote reduced environmental load, effective use of hydrocarbon resources, and socially responsible business practices.

From 2019, the rating extended its coverage and became a Eurasian one, comprising companies of Russia, Kazakhstan and Azerbaijan. Uzbekistan and Turkmenistan are to be included at the next stage. The rating covered 14 Kazakh oil and gas companies with their volumes of hydrocarbon production exceeding half a million tonnes.

Beyond that, a separate survey was conducted among KMG’s 17 subsidiaries (with a share of no less than 50% and compliant with other rating requirements). Moreover, the rating included not only upstream assets, but also companies engaged in refining and transportation with JSC Intergas Central Asia and JSC Embamunaygas taking the lead.

“The Company is consistent in improving its environmental performance. The activities taken to increase the beneficial use of associated petroleum gas allowed to reduce significantly pollutant and greenhouse gas emissions into the air, activities to dispose of waste, including historical waste, and to reclaim contaminated lands are being implemented. The programme activities being implemented and planned will promote the reduction in water consumption from surface water sources and improvement of the waste water qualitative composition. A desalination plant is under construction in Mangystau region. A Memorandum of Understanding and Cooperation was signed with the Zhanaozen Akimat for the construction of a desalination plant near the Kenderly recreation area. Integrated waste water treatment at ultra-filtration and reverse osmosis plants enables the Refineries to save up to 1.5 million m3 of fresh water per year, which was earlier taken from the municipal water supply systems. Therefore, KMG contributes to preserving favourable environmental conditions within its footprint.”

• Liquidation of historical contamination as well as liquidation of negative environmental impact sources (idle wells, waste water collectors, landfills and other production facilities).

• Reduction in environmental emissions by improving process solutions, for example, replacing heating oil with heating/natural gas used as fuel in process furnaces, using new generation additives, planting and developing the territories of production facilities, replacing equipment, extending gas refining capacities, constructing gas refining plants, etc.

• Reduction in pollutant emissions: Tazalyq project: upgrade of waste water treatment facilities of Atyrau Refinery and remediation of Tukhlaya Balka evaporation ponds.

• Overhaul of the cooling tower to increase the volume of fresh technical water by 3,000 m3 ; improvement of the performance of treatment facilities.

Within the framework of the NAMA climatic project, KTGO also plans to further increase the share of gas motor vehicles and specialised machinery within its own fleet as part of the “Transition of Motor Vehicles from Traditional Fuel (RON Petrol, Diesel Fuel) to CNG (Fleet Upgrade)”. From 2020 to 2024, the share of gas vehicles (Euro 3 class and higher) is expected to grow up to 35 percent following the fleet structure upgrade. Improvement of the fuel consumption structure and vehicle class by upgrading (purchasing new) 16 vehicles using LPG and 46 vehicles using CNG will significantly reduce hazardous substance emissions by KTGO vehicles. In 2018, the volume of hazardous substance emissions from vehicles was 17,962 tonnes, while in 2024, after implementation of the scheduled activities that will require some KZT 600 million for the entire five-year period; these emissions could be reduced to 17,144 tonnes/year or by 4.6% accordingly.

In accordance with the precautionary principle (Principle 15 of the Rio Declaration on Environment and Development adopted by the United Nations in 1992) as well as requirements of our management system and requirements of the RoK laws, an environmental impact assessment (EIA) is conducted prior to implementation of each project to identify environmental and other effects of managerial and business decision choices, elaborate recommendations for environmental enhancement, prevent the destruction, degradation, damage and depletion of natural environmental systems and natural resources. Further, public hearings with the participation of stakeholders’ representatives — administrative, government and controlling authorities, research organisations, public associations, local communities, mass media — are conducted at the designing stage of each project. We ensure access to draft EIAs for all stakeholders, accept and keep record of comments and suggestions. All draft EIAs of the KMG Group are subject to the state environmental expert review and are available to the public concerned on the Company’s official website and on the websites of local authorities throughout the entire life cycle of the project. In 2018–2019, 77 meetings with the local community and public organisations were held, including 27 meetings in 2019 and 50 in 2018. Following the public hearings, appropriate measures are taken with account of the recommendations and opinions of the stakeholders.

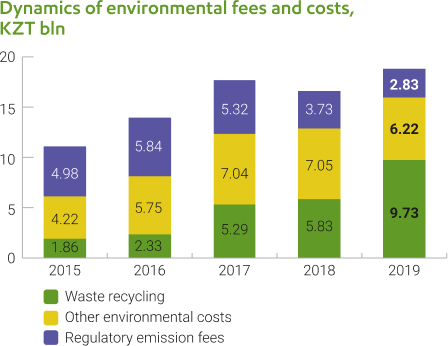

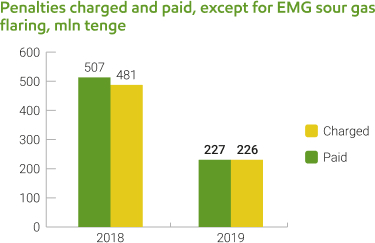

To effectively manage environmental risks, the Company is permanently improving its approaches to environmental management and allocates necessary resources for environmental protection. Environmental costs include taxes on permitted emissions, cost of environmental activities, insurance, compensatory environmental measures, investments to prevent environmental impact, etc. We increased the budget for historical waste treatment and contaminated land remediation. Investments in waste treatment increased 3 times since 2015 and make up over a third of all environmental costs. At the same time, a reduction in air pollutant emission fees is observed. Environmental costs amounted to KZT 18.8 billion in 2019, which is KZT 2.4 billion more than in 2018.

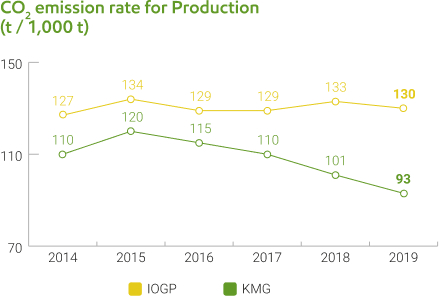

The continuation of energy efficiency activities is seen by our Company as one of the environmental protection and productivity enhancement tasks. The Corporate Centre collects and analyses energy consumption and energy efficiency data, monitors the progress and identifies areas for improvement, performs a benchmarking against the previous period and the performance of peers (IOGP).

The Company’s activities in the field of energy conservation and energy efficiency are based on the methodology of ISO 50001 Energy Management Systems, which is the best generally recognised international practice for system management in this area.

From 2017 on, KMG employs the Road Map 2017– 2020 for Energy Conservation and Energy Efficiency for KMG Subsidiaries and Associated Companies, including Jointly-Controlled Entities and Joint Ventures.

The objectives of the Road Map for Energy Conservation include:

• Increasing responsibility of the top management, introducing energy efficiency KPIs for managers in charge of energy conservation and energy efficiency

• Ensuring the efficient use of energy resources

• Reducing the payment burden by increasing the energy efficiency of energy conservation activities

• Ensuring the energy efficiency while procuring construction, reconstruction, overhaul of energy equipment

• Raising private investments for increasing energy efficiency, including under the terms of performance contracts (agreements)

• Improving the energy efficiency compliance and index monitoring system

• Complying with the legislative requirements for energy conservation and energy efficiency.

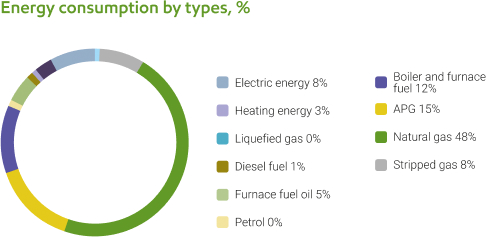

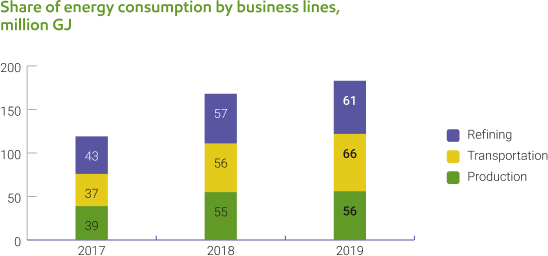

A total of 182.8 million GJ of fuel and energy resources were consumed in the reporting year — a 9% increase compared to 2018, of which 12.7 million GJ of electric energy, 4.7 million GJ of heating energy, 1.7 million GJ of motor fuel, 163.7 GJ of boiler and furnace fuel were consumed. The energy consumption volume is distributed among three business processes — Oil and Gas Production, Oil and Gas Transportation, and Oil and Gas Refining.

The increase in energy consumption compared to 2018 is first due to the expansion of operations and commissioning of new processing units to increase the oil refining efficiency and natural and associated gas consumption for own needs.

In 2019, own generated energy for the KMG Group amounted to 642.8 million kW of electric energy and 3,850.6 thousand Gcal of heating energy.

The main strategic development areas of energy conservation and energy efficiency of the Group are upgrading process equipment, introducing energy saving technologies, optimising heating energy generation and consumption as well as developing own generation sources, including those with the use of raw gas.

In 2019, 69 energy conservation and energy efficiency activities were implemented, the planned annual saving of fuel and energy resources is 0.8 million GJ, which in kind is 11.3 million kW of electric energy, 91.3 thous. Gcal of heating energy, 8,508 thous. m3 of natural gas.

This year, the energy audit of JSC Embamunaygas and JSC Karazhanbasmunay has been started, bidding procedures for 2020 energy audits of JSC Ozenmunaygas, JSC Mangistaumunaygas, LLP Kazakhturkmunay, LLP Kazakhoil Aktobe, LLP Pavlodar Refinery, LLP PetroKazakhstan Oil Products and JSC Intergas Central Asia are in place. Following the energy audits, energy conservation and energy efficiency activities to be implemented within the next 5 years will be suggested.

The refineries continue studying the current refinery development level compared to the best global refineries using the methodology of HSB Solomon Associates LLC (hereinafter — Solomon). The Solomon study is aimed at identifying the key indicators — Solomon indices — of the refineries on a comparable basis, i.e. how efficiently the existing capacities are used. The efficiency indicators are designed to compare refineries similar in size and configuration and are better to be used for prompt comparisons, enabling to compare the performance (both production and economic) of a refinery with the performance of other refineries in various groups.

Further, the upstream assets plan to introduce fiscal and technical electric energy metering as part of the Continuous Production Improvement System projects. The completion of this project will cut electric energy costs through the arrangement of reliable technical metering, efficient electric energy distribution and consumption.

Renewable energy sources (hereinafter — RES) introduced in KazTransGas subsidiaries and associated companies during previous years perform effectively: Waterkotte geothermal pumps; single-crystal solar panels (batteries); closed cycle vapour turbogenerators.

The total volume of renewable energy generated (produced) in 2019 by the KMG Group broken down by sources:

• Geothermal energy generated by heating pumps — 623.808 Gcal

• Electric energy generated by solar panels — 96,377 kW·hour in total (7,884 kW·hour + 88,493 kW·hour)

• Electric energy generated by closed cycle vapour turbogenerators (Rankine cycle) — 240,900 kW·hour.

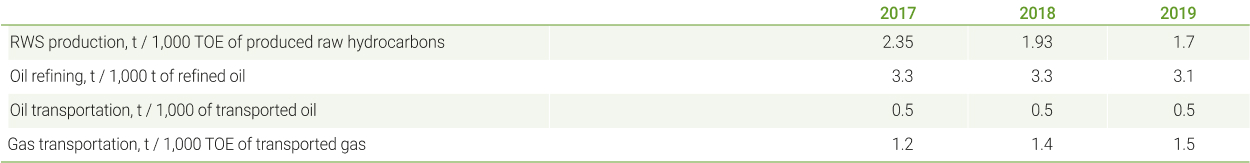

In 2019, the Group average specific energy consumption for hydrocarbons production was 2.4 GJ per tonne of produced RWC (2.38 GJ in 2018), which is still 60% higher compared to the figure of the International Association of Oil & Gas Producers being 1.5 GJ per tonne of produced hydrocarbons in 2018. Growth of specific energy consumption for oil production is first due to the increased water-cut at mature fields, since the increased water-cut increases the specific density of produced liquid and, accordingly, the consumed energy for mechanical production methods.

In 2019, the Refinery average specific energy consumption for Oil Refining was 3.7 GJ per tonne (3.5 GJ in 2018). This is 19% higher than that of the European refineries, which is first due to the severe climatic conditions at the Refineries’ location.

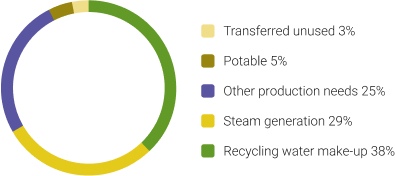

Water is an integral part of all KMG production processes. In its operations, the Company endeavours to reduce water consumption, increase the efficient use of water resources, build up water reuse and recycling, improve the quality of waste water and minimise the impact on natural water bodies.

The KMG Group’s water use activities are consolidated in the Corporate Centre, where the Company’s overall impact on the country’s water resources is analysed. The Corporate Centre also analyses achievements, problems, risks and identifies areas for improvement, objectives and tasks for further activities, performs a benchmarking of the water consumption dynamics and spacing.

In 2018, the Company adopted the corporate water resources management standard (hereinafter — the Standard) that will be gradually introduced in the Group during subsequent years. The Standard sets out KMG’s key water use principles — 8 Water Principles, systematises the water management approach of KMG’s subsidiaries and associated companies as well as helps increase the commitment of the Company’s managers and employees to saving fresh water.

LLP PetroKazakhstan Oil Products

The completed upgrade of treatment facilities has improved the efficiency of industrial waste water treatment, for oil products and suspended substances — from 76% to 98%, which decreases the environmental burden through the reduction in environmental emissions.

Extra waste water treatment stages were added to the ultra-filtration and reverse osmosis plants. The treated waste water is used in the recycling water supply system and meets the regulatory requirements. Integrated waste water treatment at the ultra-filtration and reverse osmosis plants enables to save up to 1.5 million m3 of fresh water per year, which was earlier taken from the municipal water supply systems.

In 2019, the volume of returned treated waste water and reused industrial waste water amounted to 882,721 thous. m3 , including 645,430 thous. m3 returned to the fire fighting system. Fresh water is saved for KZT 184 million. After integrated treatment at the ultra-filtration and reverse osmosis plants, 237,291 thous. m3 of treated waste water were used to make up the recycling water supply unit, which enabled to save the equivalent volume of fresh technical water.

LLP Atyrau Refinery

One of the key environmental protection activities currently implemented by Atyrau Refinery is the Tazalyq project comprising:

1.Reconstruction of mechanical treatment facilities, 2019–2022

2.. Reconstruction of biological treatment facilities and construction of a post-treating unit, 2019–2023

3.Reconstruction of Atyrau Refinery evaporation ponds, 2020–2022. Remediation of disturbed lands and construction of an underground pipeline to replace the open channel are planned.

Upgrade of the treatment facilities will help reduce water withdrawal from the Ural River through the use of a multistage waste water treatment system, which will remove up to 99% of pollutants from waste water and, accordingly, increase many times the water reuse and return up to 50% of treated waste water to operations. This project will enable to stop the operation of evaporation ponds, eliminate the impact on ground water, flora, fauna and the air in Atyrau. The project is to be completed at the end of 2023.

A desalination plant is planned to be constructed near the Kenderly recreation area in Mangystau region. The capacity is expected to be 50 thousand m3 of water per day. Currently, Zhanaozen is supplied with drinking water from a distance of 2,000 km by transportation of Volga water from the Kigach River.

As is known, the problem of water supply in Mangystau region is very urgent, as the region is located in the semi-desert area with limited water resources. Apart from oil and gas producing companies, the Astrakhan — Mangyshlak water pipeline provides Volga water to the population, industrial facilities, utility and governmentfunded organisations, agricultural producers. However, water consumption volumes grow as the population grows and new enterprises come into being, therefore the water pipeline capacities are insufficient, despite improvements in the drinking water supply system.

Besides, KMG provides the region with water not only through the pipeline but through the desalination plants as well. Currently, a desalination plant is under construction at Karazhanbas Field, which will help release at least 17 thous. m3 of Volga water per day.

Conducting its operations in the region and realising its responsibility, the KMG Group is interested in gradual social and economic development of Mangystau region. The construction of desalination plants will have a positive effect on the population of not only Mangystau region but of Atyrau region as well.

In 2019, KBM started construction-and-assembly works for the desalination plant. The plant is planned to be commissioned in December 2020. The desalination plant is designed to treat and dispose of reservoir water and supply with technical water in order to increase the reservoir recovery at Karazhanbas Field by steam injection into the reservoir. This is going to be Kazakhstan’s first plant powered by foreign technologies and foreign investments.

The total water withdrawal of the KMG Group in 2019 amounted to 93.609 million m3 and remained at the same level (2018: 93.660 million m3 ).

Midstream water withdrawal has grown since 2018 as a result of refinery upgrades that were completed, and consequential increase in oil refining capacities and depth.

In 2019, the Group discharged 10.980 million m3 of waste water (10.847 million m3 in 2018). Waste water from KMG entities is mainly sent to (and end up in) various dedicated receivers: collection ponds, evaporation ponds and filtration beds. These facilities are engineering structures intended to treat waste water naturally and avoid environment pollution. Entities that have no own reservoirs have their waste water treated and disposed of by special companies. Discharged water quality standards established by the environmental law are achieved by mechanical and biological waste water treatment.

Retreated water is reused to wash vehicles, suppress dust and make up fire fighting systems. Considerable portion of treated waste water is only reused by refineries, thus, 3.2 million m3 of treated waste water was reused in 2019 (4.1 million m3 in 2018); the water was mainly used to make up recycling water supply units. KMG plants reused 19% of water, which is below the level achieved in 2018 by 7% (of Midstream water withdrawal).

Volume of water reused in 2019 dropped against 2018 due to generally lower water consumption by units of POCR. AR reused less water because less waste water was used to make up cooling towers as the treated waste water at biotreatment facility outlet contained salt, and completely stopped using treated waste water to irrigate sanitary protection zones, as the sanitary protection zone covered alkali soils and was naturally saline.

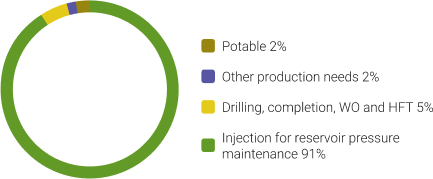

After the advanced treatment unit of the biotreatment plant is upgraded in 2023, 50% of treated waste water is planned to be reused. In 2019, the recycling water supply systems of KMG Refineries used (circulated) total of 463 million m3 of water (399 million m3 in 2018). Recycled water circulation in 2019 increased against 2018 as the result of new units being commissioned after refineries upgrade. Oil production generates large volumes of so-called produced associated water: water-oil emulsion is drawn to surface, which is then separated into water and oil by gravity. After settling in this manner, water is injected to the reservoir. Out of 129.1 million m3 of associated water produced in 2019, 99% was re-injected to maintain reservoir pressure, and only 1 % was re-injected in absorbing wells. The fact that volumes of produced associated water are substantial and gradually increase suggests that oil reservoirs are depleting (watered out). In 2019, 47.763 million m3 of water from other sources (19.4 million m3 of sea water, 6.5 million m3 of Volga water and 21.8 of underground water) was additionally injected to maintain reservoir pressure.

The Company has a considerable impact on water bodies in the west of Kazakhstan (Ural River, Kigach River, Kokzhide Sands, Pyatimarskoe Reservoir), which have special environmental, economical, historical and cultural, recreational value. Regular monitoring is implemented to prevent adverse impact on susceptible ecosystems.

Golden eagle

We understand that biodiversity is the key to environmental well-being. According to UN GC Principles 7 and 8: “Businesses should support a precautionary approach to environmental challenges” and “Businesses should undertake initiatives to promote greater environmental responsibility.” Further, SDG 14 and SDG 15 aim to “conserve marine and terrestrial ecosystems.” Accepting responsibility and demonstrating its commitment to the UN GC and SDGs, KMG works on conserving biodiversity within the Company footprint and minimising effects of its operations on flora and fauna.

Biodiversity management is based on the following key principles:

• Identification and assessment of environmental and social risks and impact. To achieve this, when planning our future activities we evaluate potential impact on biodiversity.

• According to international practice, to monitor changes in environmental situation in the contract territories during exploration and development of oil fields, and to evaluate and specify potential damage to biodiversity, regular environmental monitoring focusing on specially protected natural sites and conservation areas.

• Implementation of precautionary and preventive activities and measures to reduce impact, and, where residual impacts remain, remedial activities to compensate for consequences of adverse impacts.

• Continuous improvement of HSE management system.

KMG Upstream SACs which operate onshore continuously monitor flora and fauna. The following studies take place to collect data on condition of natural sites:

• Floristic studies

• Ornithological studies

• Observations of land mammals.

Vegetation is monitored by periodic description of phytocenoses including species composition, abundance, general and individual projective cover of soil, arrangement, phenological development and general condition of species. The areas of focus:

• Rare, endemic and relict plants

• Presence of species stimulated for development by economic activity

• Signs of transformation or degradation of vegetation.

Environmental features of habitat with various man-made impacts, including pollution, are also described.

Fauna monitoring defines the following fauna categories: common species, predominating species, endemic and rare species recorded in the Red Book of Kazakhstan; potentially endangered and vulnerable species; migratory, non-migratory and nesting birds. Recorded and noted are bird nests, how animals are spread across the observed area of a field. Fauna observation evaluates habitable conditions, reproduction opportunities, food reserves, the presence and nature of the mammals’ shelters, birds and reptiles, amphibians.

Close attention is paid to establishing species composition, number of rare and endangered faunal and floral forms listed in the Red Book of Kazakhstan and IUCN.

On 12 August 2018, during the Fifth Caspian Summit in Aktau, the Republic of Azerbaijan, the Islamic Republic of Iran, the Republic of Kazakhstan, the Russian Federation and Turkmenistan signed the Convention on the Legal Status of the Caspian Sea (hereinafter — the Convention), which was ratified by the Republic of Kazakhstan on 8 February 2019. In accordance with the Convention, all Caspian bordering countries strive for creating favourable conditions to develop mutually beneficial economic cooperation in the Caspian Sea region. Considering that exploration and production of hydrocarbons is an important part of economic development of the Caspian bordering countries, and promotes better human welfare, conserving environmental balance and unique Caspian Sea ecosystem becomes of special importance. Among other things, the Convention prioritises environmental issues, more specifically, it obliges all Caspian bordering countries to “protect and conserve ecological system of the Caspian Sea and all its components.” According to the Convention, “ecosystem of the Caspian Sea is interacting components of air, water and biological organisms, including human beings, within the Caspian Sea and parts of the land affected by the proximity of the Sea.”

As part of ensuring compliance with the Kazakhstan environmental law and guided by the particular importance of the Caspian Sea, oil operations in the Kazakhstan sector of the Caspian Sea provide for baseline environmental studies including such components and parameters of the environment as bottom sediments, benthos, phytoplankton, zooplankton, marine vegetation, ichthyofauna and so on.

KMG also manages potential risks of adverse impact on biodiversity from accidents, and provides for activities to conserve animals as part of their Oil and Oil Products Spill Response Plans.

In our offshore operations, we strictly adhere to the following principles:

• Strict compliance with design solutions

• Zero discharges — all wastes and waste water are removed to land

• Fish protection devices for all floating crafts, no bilge water

• Operations are prohibited during spawning season from 1 April till 15 July

• Fishing using industrial vessels is prohibited

• Well testing and raw hydrocarbons combustion are prohibited at night

• Special usage conditions.

North Caspian republican conservation area

North Caspian is the most productive part of the Caspian Sea. This part of the sea is rich with bioresources. There are 25 species of main commercial fish species, of which the most valued are sturgeons with 70–80% of the global reserve living in the sea basin.

Eastern area of the North Caspian with deltas of Volga (within Kazakhstan) and Ural is a part of the State Conservation Area in the North Caspian. Wetlands of the North Caspian, particularly deltas of Volga, Ural and Emba, and the adjacent coast and the sea itself are essential for Eurasia and support millions of water birds and semiaquatic birds during nesting, moulting, seasonal migrations and wintering. One of the largest Eurasian flyways, the Siberia — Black Sea — Mediterranean Sea flyway, crosses the North Caspian.

According to the baseline studies, more than 70 bird species (including 5 rare species listed in the Red Book of Kazakhstan) migrate through open areas of the North-East Caspian 20–60 km away from the shore. Little egret, spoonbills, pelicans, whooper swan, ferruginous duck and great black-headed gull are nesting near the shore. Swamphen, white-tailed eagle and osprey are also observed flying.

Land cenoses are nesting grounds for 5 species listed in the Red Book of Kazakhstan. Steppe eagle is the most common one. As for rare birds, avocets, oystercatcher, little egret may be observed in these areas.

Caspian seal

The only large marine mammal (pinnipeds) of the Caspian Sea is Caspian seal (Phoca caspica). It is an endemic mammal species. Seals are spread all across the Caspian Sea, although they vary in number in the North part depending on a season. Seasonal distribution of animals across the sea area is based on three main phases of the annual cycle: reproduction, moulting and feeding. Reproduction grounds are in the North Caspian, which freezes in winter. During feeding period from April till September, seals mainly stay in the Middle and South Caspian. In summer, only a few animals (about 30,000) remain in the North Caspian, the majority of population move to the deeper and colder South Caspian. They migrate to the North shallow waters in the late autumn, where water starts to freeze. The majority of population gathers in the North Caspian in October — November.

This area is essential to conserve biodiversity in Kazakhstan and the entire Eurasian continent and it needs to be continuously monitored and timely protected. From the very beginning of its operations in the North Caspian, KMG has focused on protection of environment of the region.

Republican Novinsky State Natural (Faunal) Reserve was established to create better conditions for reproduction of flora and fauna, including species listed in the Red Book of Kazakhstan. Protection status: a reserve.

Jeyran

Zhambyl is in the northern part of the Caspian Sea. The contract territory is within the Caspian Sea conservation area, and a part of it covers Novinsky Reserve, although industrial sites do not affect environmentally sensitive areas. This area has restrictions for production operations during the most environmentally sensitive period. Over the period under studies, there were no recorded abnormalities in natural conditions, environmental situation or unnatural factors, which would cause concerns or require closer attention.

Isatay is in the northern part of the Caspian Sea, 45 km north of the coast of Bozashy Peninsula, in Mangystau Region.

Dead Kultuk (Ustyurt) is the habitat of the most characteristic Caspian species: flamingo, which was common in the north-east in the past, and is still using this part of the sea, moulting and summer birds near Komsomolets bay and Dead Kultuk shor and Kaidak.

Flamingo (Phoenicopterus roseus) is a locally nesting, decreasing species. It is the only specimen of its species in Kazakhstan fauna. Until now, the main nesting grounds in Kazakhstan included Tengiz Lake, Chelkarteniz Lake and north-eastern coast of the Caspian Sea.

Komsomolets bay, Dead Kultuk and Kaidak shors are still regularly used by thousands of birds to spend summer and moult. Birds from Central Kazakhstan fly through these areas and enlarge the local non-nesting population in April and August-September. Up to 35 thousand birds migrate through Komsomolets bay each year.

Mangystau Region. Mangystau Region has a vast system of designated nature conservation areas including Ustyurt State Nature Reserve and republican Kenderli-Kayasan Conservation Area, as well as 8 reserves and 1 regional natural park. Blotched snake (Elaphe sauromates) is a reptile listed in the Red Book of Kazakhstan (2010) and inhabiting Mangystau Region. Afghan tortoise is a common, well spread species, which is quite numerous in local areas of Mangystau Region, nevertheless, according to the Red List of International Union for Conservation of Nature (IUCN) it is a vulnerable species.

Republican Kenderli-Kayasan Conservation Area was established to preserve habitat and natural reproduction grounds of chlamydotis and saker falcon. Established status: a conservation area, reserve/nature reserve, controlled area.

Ustyurt State Nature Reserve has the highest category of republican designated nature conservation areas. Ustyurt State Nature Reserve (USNR) was founded with the main goal of preserving the natural state of unique natural complexes, historical monuments, flora and fauna of Kazakhstan deserts. The Reserve is the main habitat of several species listed in the Red Book of Kazakhstan and/ or International IUCN Red List: goitered gazelle, Ustyurt mountain sheep (urial), caracal, honey badger, saker falcon, golden eagle, Eurasian eagle-owl, white scavenger vulture, chlamydotis, etc. According to the leading experts, the USNR meets the criteria of a UNESCO World Heritage Site and may be honoured as one in future to prove the highest level of recognition internationally.

In 2018, for the first time in the entire USNR history the observations located a living Persian leopard. Formerly, leopard was only known in Kazakhstan because it was killed by human 3 times, including twice in Mangystau Region in 2007 and 2015. Leopards sometimes get to Mangystau from the neighbouring Turkmenistan, and considering the adequate food reserves (mountain sheep and goitered gazelle), they might possibly form a local population if they were not hunted by human and if the habitats were properly protected. There is at least 600 km between the Ustyurt Reserve to Kopetdag in Turkmenistan, where the leopard is known to live for a fact.

It should also be noted that leopard is not currently on the Kazakhstan fauna lists or in the Red Book of Kazakhstan. The USNR employees have already addressed the Forestry and Wildlife Committee of the Kazakhstan Ministry of Agriculture with the suggestion to immediately record the Persian leopards in the Red Book of Kazakhstan to ensure the necessary legal status for the species efficient protection.

Over the last decades, certain species of mammals that are new for the region were found: desert long-eared bat in West Ustyurt, lesser mouse-eared bat and common noctule in North Ustyurt, honey badger in South-Western Ustyurt, golden jackal in Mangyshlak plains and Karagiye Depression, raccoon dog. Striped hyena was encountered in West Ustyurt and signs of Indian crested porcupine were observed, which has not been recorded in the area for more than 40 years.

Kansu is in Karakiya District of Mangystau Region, partially lays within Kenderli-Kayasan conservation area and borders Ustyurt State Natural Reserve (2 km of buffer zone from the site boundaries). No geologic exploration work was carried out on the site in 2016. Due to high geological, environmental risks and non-profitability, KMG made a decision to exit the project. In 2019, the procedure for return of the contract territory to the government started.

Samtyr Since 2018, KMG holds a 50% participation interest in LLP Samtyr, Mangystau Region. It lays within SouthUstyurt sedimentary basin in the vicinity of Uzen, Shakhpaty, Dzhel fields.

Kokzhide-Kumzhargan, Local State Nature Reserve. This reserve accommodates two sites of the republican nature reserve fund: Kokzhide Sands and Kokzhide Groundwater, which are included in the List of Republican and International Geological Sites of the State Nature Reserve Fund.

Urikhtau, Alibekmola and Kozhasai fields are located in Mugalzhar District of Aktobe Region, Kazakhstan. Northwestern part of the contract territory within Urikhtau Field ays within the Kokzhide Sands, the fields also border Kozhide-Kumzhargan Local State Nature Reserve. To avoid groundwater pollution, environment is being regularly monitored both within the Group operations footprint and near the Kokzhide Sands adjoining the contract territory.

Karazhanbas Field is in the north-western part of Buzachi Peninsula, within Caspian Depression, in the territory bordering the Caspian Sea on the west. The field’s west borders the State Nature Conservation Area of the North Caspian. Industrial environmental monitoring includes bi-annual flora and fauna monitoring.

Production sites within and near designated nature conservation areas

West Kazakhstan Region. Rozhkovskoe Field is a part of Fedorovsky block, which lies within the northern flank of the Caspian Depression. Boundaries of Fedorovsky block were determined by a geological allotment of 1,291.37 m2 . A prospective element of this exploration block is Chinarevskoe crystal base emergence, which exposed Rozhkovskoe Gas Condensate Field and local subsalt structures, which could bear oil and gas.

Geologic exploration resulted in location of Rozhkovskoe Field among structures of Fedorovsky block, and in 2015, Contract for Gas and Condensate Production at Rozhkovskoe Field No. 4130 UVS-ME was signed.

Nine kilometres from Rozhkovskoe Field there is Kirsanovsky State Nature Reserve.

Kirsanovsky Republican State (Integrated) Nature Reserve was established by Resolution of KazSSR Council of Ministers dated 17 February 1986 No. 69, Resolution of the Kazakhstan Government dated 27 June 2001 No. 877 and Resolution of the Kazakhstan Government dated 19 July 2005 No. 746. It is permanently valid. The Nature Reserve was established to conserve and reproduce rare and endangered flora and fauna species, preserve integrity of the entire natural complex. It occupies 61 thousand ha in the Ural River flood plain, from Eltyshovka River and low reaches of Utva River in the north, to Ozernoe and KabylTyube villages in the south. This territory is currently a part of Zelenovsky, Burlinksy and Terektinsky districts.

The main mission of Kirsanovsky Nature Reserve is to acclimatise and re-acclimatise beavers. The Nature Reserve area which spreads across the Ural valley is predominated by river valley landscapes with flood-plain forests and oxbow lakes overgrown with shrubs, cereal, grass and reed meadows. Multiple water birds are nesting here. The Nature Reserve is the only Kazakhstan habitat of small colonies of beavers, which proves its national economic significance.

The area is within a tectonic deflection between Obshchy Syrt and Poduralskoe Plateau. In its centre, there is a modern Ural River plain 3–7 km wide, upland fringes enlarge the valley to 10 km. Right bank of the plain adjoins Rubezhinsko-Yanvartsevskie Sands formed by deltaic deposits of the Khvalyn Sea.

Fauna of the Ural River plain mostly consists of eurychoric species: Holarctic, Palaearctic, Mediterranean species which are the considerable percentage.

There are over 2,000 insect species in the concerned area, including 29 species listed in the Red Book of Kazakhstan, 15 rare and small-numbered species; 26 fish species including 4 rare ones (Acipenser, Acipenser stellatus, Huso huso, Acipenser nudiventris); 7 amphibians, 2 smallnumbered species (Bombina bombina and Pelobates fuscus); 26 reptiles including 2 rare species (Coluber and Zootoca vivipara); about 65 species of birds (3 rare species: Pandion haliaetus, Haliaeetus albicilla Linnaeus, Bubo bubo); 23 species of mammals including 4 species recorded in the Red Book of Rare and Endangered Animals of the Republic of Kazakhstan (Desmana moschata Linnaeus, Martes martes Linnaeus, Mustela lutreola Linnaeus, Alces alces Linnaeus).

Bubo bubo chicks

In 2019, the baseline environmental studies (Isatay), well drilling and testing (Zhambyl) took place in the sites within the North Caspian state nature conservation area. There are currently no significant man-made effects in these regions, which would restrict free movement of wild animals and birds within their habitats. During drilling operations, the following activities have environmental impacts: drilling rig installation, well drilling and testing, navigation. Among impact factors are increased concentrations of suspended solids in water during offshore construction, disturbance of natural structure of bottom deposits due to intensive navigation among other things, physical effects of noise.

LLP Zhambyl Petroleum compensates for damage to fish reserves by purchasing young sturgeons from fish farms and releasing them into Ural River. This effort is supported by LLP Kazakh Research Institute of Fishery, which studies food reserves of sturgeons, purchases and releases young fish into Ural River. In 2019, about KZT 7.5 million was spent for these activities.

Construction of an appraisal well in East Urikhtau Field and an appraisal directional well in South Urikhtau Field has started in Urikhtau, which shares borders with designated nature conservation lands. Groundwater impact factor is the well drilling which may pollute groundwater. Pollutants may also enter groundwater with infiltrating precipitations from the surface of industrial and domestic waste accumulations, oil-contaminated areas, oil and produced water storage areas. In this respect, KMG implements certain measures to protect groundwater and prevent it from being polluted, littered or depleted. Well design isolates groundwater reservoir by running a casing down to 80–85 m, and regular observations are performed over occurrence, level and quality of groundwater in currently and potentially polluted areas.

Another impact factor of industrial development of the territory on biodiversity is power transmission lines, which pose major danger for birds. The network of overhead power lines is constantly expanding and invades natural bird habitats, often causing their mass death. This is of special concern for predatory birds living in forest-free steppes and semi-deserts where overhead line pylons are the most attractive for the birds to sit on.

In 2019, KMG continued its efforts to prevent death of rare birds on overhead lines. JSC Embamunaygas installed bird protection devices on insulators of overhead line pylons; branches of JSC ICA install bird protection devices on insulators of cross arms and hooks of overhead lines as they break, and bird-protection devices are also installed during major repairs and construction of overhead power lines.

In October 2019, JSC ICA supported the initiative of LLP Dostyk Advisory and took part in an expedition to study the adverse effect that overhead lines have on bird population in Atyray Region. In 2019, in its facilities Umirzak-SPN 112 km (30 km) and Zhetybai-SPN 112 km 65–112 km (57 km), JSC KazTransOil repaired 6 kW overhead lines and used self-supporting insulated conductors which fully prevent death of birds when they sit on overhead power lines.

To improve knowledge and awareness of the KMG Group employees, and to promote careful attitude towards natural resources, corporate newspaper Munaily Meken published article titled Care for Nature is our Common Responsibility. In addition, in order to raise environmental responsibility and enhance transparency of oil & gas companies, information about environmental performance, including biodiversity and monitoring results, was published on the KMG and SAC websites.

Each of us can contribute to conservation of biodiversity in our country by following simple rules:

• Do not litter streets and nature

• Care for environment

• Do not engage in illegal hunting and fishing

• Focus on conservation of biodiversity when planning environmental activities

• Report violations of environmental law by legal entities and individuals to authorized officers and to hse@kmg.kz;

• Record red-book listed animals and plants in an area by taking photos and tagging locations, and send to hse@kmg.kz;

• Participate in campaigns and programmes to preserve biodiversity in Kazakhstan

• Send your initiatives, ideas and projects to hse@kmg.kz.

We make it our highest priority to minimise our impact on environment through compliance with environmental law, rational use of natural resources and continuous improvement of our environmental activities. Our priorities include careful and rational use of natural resources, minimisation of environmental risks. Target Programmes are intended to reduce raw gas flaring, develop green energy based on renewable energy resources and generally increase energy efficiency.

The KMG Corporate Centre manages activities of subsidiaries and associated companies with regard to greenhouse gas and pollutant atmospheric emissions, monitors that all permits for activities are obtained in due time, such as emissions permit, greenhouse gas quota, raw gas flaring permit.

Atmospheric impact minimisation programmes include raw gas development and refining programmes for production sector, oil refineries upgrade programme, application of the latest available technologies in the construction of new transportation facilities, etc. Gradual implementation of these programmes will result in reduced pollutant and greenhouse gas emissions into the air, increased benefits from using raw gas.

In 2019, the KMG Group approved the Emissions Management Policy, which defines atmospheric impact minimisation philosophy:

1. Operating in strict compliance with the law and other Company commitments

2. Following the established pollutant emission standards and emission limits, greenhouse gas quotas

3. Clearly allocated functions and duties, increased competence, training and awareness

4. Regular recording, inventory checks and monitoring of emissions

5. Ending regular flaring of raw gas during hydrocarbon production operations

6. Activities to reduce greenhouse gas emissions and carbon footprint

7. Management of carbon assets

8. Continuous improvement of emissions management activities.

We comply with the national laws, best international standards, provisions of corporate HSE documents and other corporate documents, identify and assess environmental risks, ensure that our environmental activities are transparent and open.

We are still working on improvement of our facilities’ operations to reduce the atmospheric impact. We take active part in improvement of regulatory framework of the country, hold meetings of Emissions Management Work Group, participate in climate change forums, conferences, enhance our knowledge and skills to improve our abilities in emissions reduction strategy.

KMG’s Long-Term Development Strategy defines the following climatic priorities:

• Managing greenhouse gas emissions

• Reducing regular flaring of associated petroleum gas

• Improving performance in emissions intensity per volume of production and increasing energy efficiency.

We are committed to increase oil and natural gas production to meet the world’s growing demand for energy, that is why we primarily focus on activities to minimise adverse impact our operations have on the environment through compliance with the environmental law, rational use of natural resources and continuous improvement of our environmental activities.

As a party to UN GC, we recognise the importance of activities to prevent climate change, and are determined to make our contribution to achieve SDG 13: Climate Action. Our responses to climate change and climate change adaptation are reflected in our strategic documents and corporate policy. The year 2019 marked the first time that we took part in The Carbon Disclosure Project (CDP) initiative, which is an international association of investors disclosing information about greenhouse gas emissions and climate change risks, and started working on evaluating the total carbon footprint of the commercial yield, from wellhead to a final consumer, under Climatic Programme. In 2020, we want to extend our reporting also to the CDP Water Disclosure Project. Our climate change priorities: reducing green gas emissions, increasing effective use of associated petroleum gas, increasing energy efficiency and energy saving, etc.

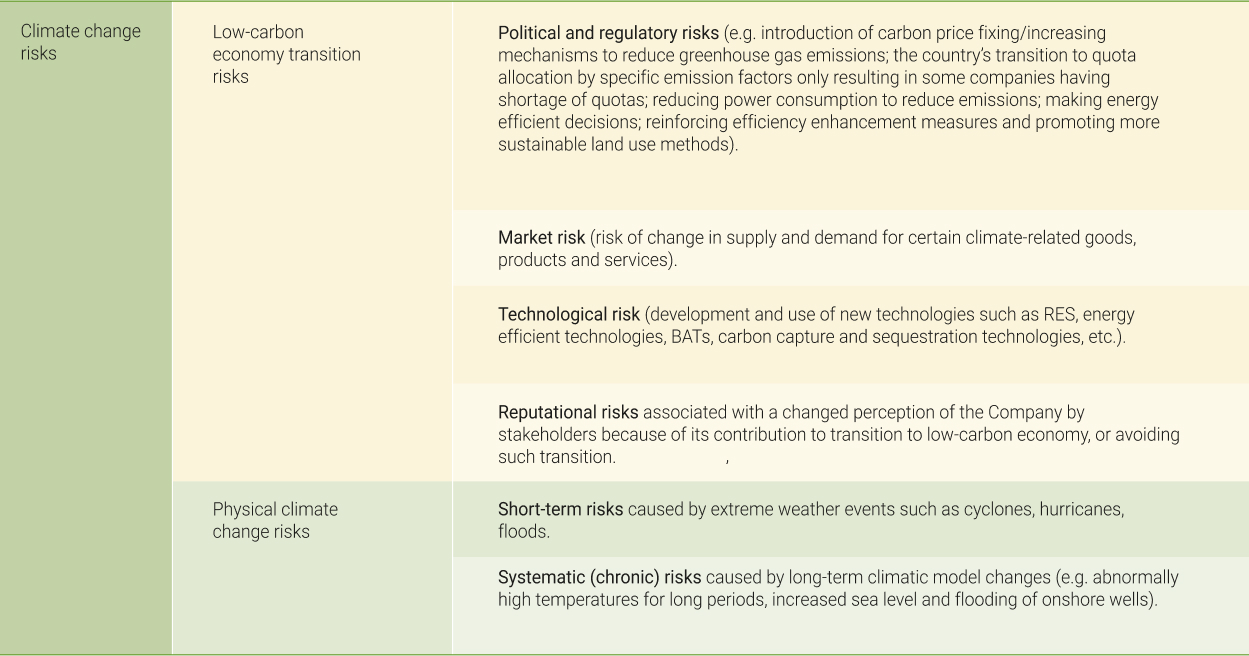

Corporate risk management system is the key element of the corporate management system and is aimed at timely identification, assessment, monitoring and mitigation of potential risk events which may have adverse effect on strategic and operational goals. The Company accepts climate change risks and is committed to make its contribution to sustainable future with minimised environmental impact and greenhouse gas emissions at every stage of its operations. In 2019, the Corporate Risk Register was expanded to include a new climate change risk. We quarterly report on HSE risks to the Board of Directors.

On 29 July 2019, KMG for the first time published a verified Greenhouse Gas Emissions Report 2018 under the CDP’s (Carbon Disclosure Project) Climate Program. The Report comprises data on the volumes of direct and indirect greenhouse gas emissions for all KMG assets, including subsidiaries in Romania and Georgia. The carbon dioxide (CO2 ), methane (CH4 ), and nitrogen oxide (N2 O) figures are factored in. Information on greenhouse gas emissions of the KMG Group for 2019 will be disclosed in the CDP report in Q3 2020.

On 26 November 2019, the first KMG Forum on Greenhouse Gas Emissions Control (Climate Session) was held in Nur-Sultan.

Attended by about one hundred representatives of various industry players, the Forum became a venue for a constructive dialogue of professionals, a platform for sharing experience and knowledge. The lively discussions held during the Forum were devoted to the challenges of managing KMG greenhouse gas emissions, expected changes in greenhouse gas emissions regulations, trading in quotas, KMG’s reporting under the CDP’s Climate Programme, etc.

A reduced rate of greenhouse gas emissions is observed for the Production business line due to gas flaring reduction activities.

We conduct operational environmental monitoring and take measures to reduce air pollutant emissions generated by the operations and processes.

As part of the operational environmental monitoring programmes, observations of air emissions are made in the designated sampling points and measurements are taken to assess the potential impact. The bulk of pollutant emissions is generated by heating gas burned in boilers, process furnaces and compressors, gas turbine plants, compressor stations, gas flaring, etc.

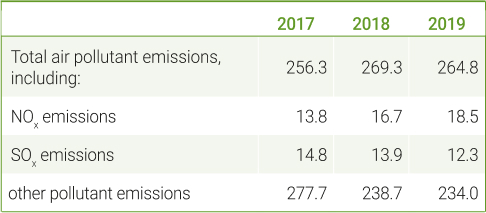

The permitted volume of all pollutant emissions within the Group amounted to 264 thous. tonnes in 2019 (269 thous. tonnes in 2018). A slight reduction in emissions is seen.

Gross air pollutant emissions within the KMG Group, thous. t

The volume of pollutant emissions for the Production business line is reduced by 10% compared to 2018, and by 27% compared to 2017 due to the increased beneficial use of raw gas and, respectively, reduced gas flaring. The Oil Refining business line sees a 5% reduction in emissions compared to 2018. The Transportation business line sees an increase in emissions due to the commissioning of new sources and growth of gas exports.

The completed projects for upgrade of the oil refineries enabled better environmental performance of fuel produced by the refineries through the manufacture of C4 oil products of the European quality standards in compliance with the Customs Union Technical Regulations. A 13% reduction in sulphur oxide/dioxide (SОx ) as compared to 2018 is due to a reduction in gas flaring in the upstream operations. An increase in NOx emissions in 2019 is due to growth of gas export and commissioning of new plants at the enterprises.

At this point, we do not make direct, real-time measurements using, for example, gas analysers, however, in accordance with the new Environmental Code, the authorised environmental body plans a company-wide switch to automated monitoring of pollutant emissions by installing sensors / gas analysers at emission sources of Category 1 natural resources sites. Currently, some organisations are developing design documentation for switching to online monitoring of pollutant emissions.

In its operations, the Company does not emit persistent organic pollutants.

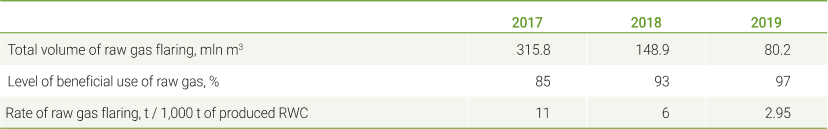

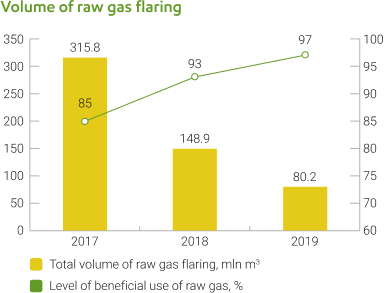

This section reflects data on upstream companies where processes related to production and beneficial use of raw gas are in place. One of the most important tasks in reducing greenhouse gas emissions is to increase the beneficial use and utilisation of associated petroleum gas, minimising gas flaring. In 2019, 97% of associated petroleum gas was utilised, the rate of gas flaring was 2.95 tonnes per 1,000 tonnes of produced RWC (11 in 2017, 6 in 2018), which is almost 51% lower than KMG’s rate for 2018 and lower than IOGP’s rate (International Association of Oil & Gas Producers) — 10.5. In 2015, KMG supported the World Bank’s “Zero Regular APG Flaring by 2030” initiative. The Company does not re-inject APG into reservoir. The construction of infrastructure and advanced capacities for raw gas utilisation enable a full-scale development of upstream assets and a considerable reduction in greenhouse gas emissions into the atmosphere.

KMG’s operations inevitably involve generation of considerable volumes of hazardous waste. In order to minimise the impact of waste on the environment, KMG continually plans and implements waste management activities. Such activities comprise accounting for generated and accumulated waste (including that of contractors), gradual reduction in waste generation volumes, safe storage of waste until it is reused or treated, KMG allocates significant funds to treat the waste generated and accumulated across all its contract territories.

The waste management performance is regularly reviewed and assessed within the KMG Group, advanced methods and modern technologies of waste management are considered so as to be implemented at production facilities.

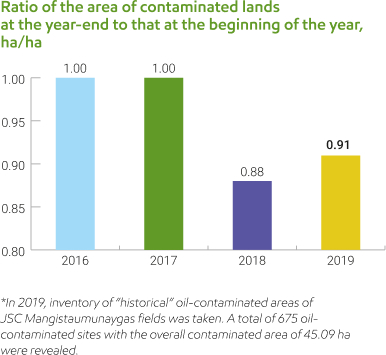

The critical task that KMG faces today is the liquidation of historical contamination and clean-up of oil-contaminated areas. In this regard, studies were conducted to take inventory of historical contamination; plans to liquidate all historical contamination were developed subject to the specifics of each field, region, and climatic conditions. In addition, on 6 August 2019, a Memorandum of Environmental Cooperation was signed between the Kazakhstan Ministry of Ecology, Geology and Natural Resources and KMG, which is aimed at disposal/ treatment of waste stored in the unorganised sludge collectors (OMG) and clean-up of oil-contaminated lands in Mangystau Region.

On 2 October 2019, the KMG Historical Waste Disposal and Treatment Technologies Forum was held in Aktau. The Forum was attended by over 30 companies that provide such services. The objective of this event was to meet with Kazakhstan’s providers of oily waste treatment/ disposal services and to explain them the requirements for the quality, scope and timing of services for the KMG historical waste treatment/disposal so as to help them assess their capabilities and decide on the use of new technologies.

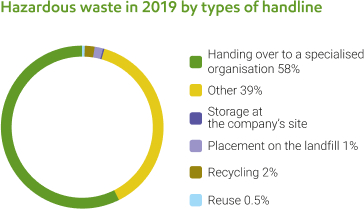

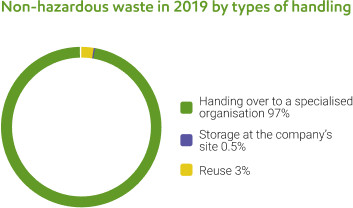

The Forum also presented a category-based procurement strategy — Waste Disposal (historical contamination), which will further serve as a basis for the procedure for procuring historical contamination disposal and oilcontaminated area clean-up services. The overall weight of waste in circulation for 2019 was 997.2 thous. tonnes, including waste classified as “hazardous” — 972,3 thous. tonnes, and “non-hazardous” — 24.9 thous. tonnes, accordingly.

Fifty-eight percent of waste is handed over for contractbased treatment by specialised companies, 39% of waste is treated by biological method, other significant waste handling methods include recycling, placing on the landfill and reuse. Three hundred and twenty-five thousand tonnes of historical waste and oil-contaminated lands were treated out of the bulk of hazardous waste.

In 2019, JSC Embamunaygas reclaimed historically oil-contaminated lands and cleaned up 35 ha of oil-contaminated lands (125 thousand tonnes of oil-contaminated soil), 200 thousand tonnes of oilcontaminated soil from unorganised sludge collectors were treated in the premises of JSC Ozenmunaygas. Nine out of 11 landfills for oily waste storage were fully cleaned up and liquidated at JSC Mangistaumunaygas production facilities by the end of 2019, the solid domestic waste landfill is in the process of liquidation, which is planned to be completed in 2020. In 2019, JSC “KazTransOil” reclaimed 1.775 ha of disturbed lands (historical contamination) at section 984–985 km and 1,016.3 km of the Uzen — Atyrau — Samara trunk oil pipeline of Uralsk LODS, the volume of treated oilcontaminated soil amounted to 38,238.9 tonnes.

As part of the upgrade of treatment facilities, an oily sludge treatment unit was built and commissioned. Oily sludge treatment on the decanter plant is arranged with a three-phase distribution of oily sludge and with trapped oil products being returned to the process. This activity enables prevention of the accumulation of oil products in the company’s sludge collectors, which also improves the environmental situation.

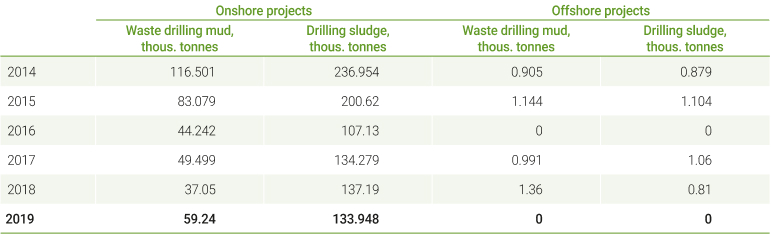

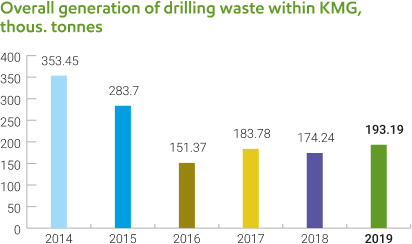

In 2019, KMG’s upstream companies generated 193.19 thousand tonnes of drilling waste (11% more than in 2018), including: 59.24 thousand tonnes — waste drilling mud; 133.948 thousand tonnes — drilling sludge. All drilling waste generated by the KMG Group’s upstream companies are handed over for disposal by specialised organisations. The methods of further waste disposal used by these companies include inertisation, thermal method, chemical method, biological remediation and burial on specialised landfills.

The safety of operations, personal safety of employees and environmental safety directly depend on the competence of employees. The safety culture aimed at achieving one hundred percent safety rests on the high qualification, awareness and professionalism of the staff. Thus, ensuring the competence of employees becomes essential for development process. The average number of academic hours per employee trained in HSE within the KMG Group is 17.

Over 34 thousand employees were trained for free in occupational health and safety, industrial and fire safety as well as safe driving under the training model introduced within the KMG Group — “70/20/10 — on-the-job/in-house/ out-of-house training” on the basis of own 6 Training Centres. JSC Ozenmunaygas (Zhanaozen), JSC “KazTransOil” (Aktau), JSC Intergas Central Asia (Atyrau, Shymkent), LLP Pavlodar Oil Chemistry Refinery (Pavlodar) and LLP Oil Services Company (Aktau) have their own training centres. In addition to their own teaching staff, the centres engage line managers and highly skilled specialists from among operations personnel, who have long record of service in operations, to provide training and professional development for personnel. Mentoring and internal coaching programmes with the involvement of experienced employees are implemented, master classes and trainings are conducted, various contests among advanced employees are held, which enables to improve internal communications and encourage people to be the best in their professions.

Training under the NEBOSH international programme was conducted within the KMG Group, training certificates were issued. Twenty employees were trained under this programme.

Seventy-eight employees of KMG’s Corporate Centre were trained in HSE. Further, 7 employees completed certification training under the NEBOSH programme, 3 employees — under the IOSH programme, and 3 employees — under the IEMA programme. Thus, KMG is committed to improve the safety culture in compliance with international standards and to ensure the effective functioning of the HSE management system. In general, the dynamic growth of figures shows that HSE training remains in demand within the KMG Group. Considering the specifics of the Kazakhstan oil and gas sector as well as mandatory requirements of the RoK laws for compulsory learning, training and professional development of personnel in general, more priority is given to occupational health and safety, industrial and fire safety.